Hoisting type locomotive battery swap station and battery swap method

A hoisting and power station technology, applied in charging stations, vehicle parts, electric vehicles, etc., can solve the problems of high capital construction investment and maintenance costs, and achieve low construction investment and maintenance costs, fast battery replacement, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

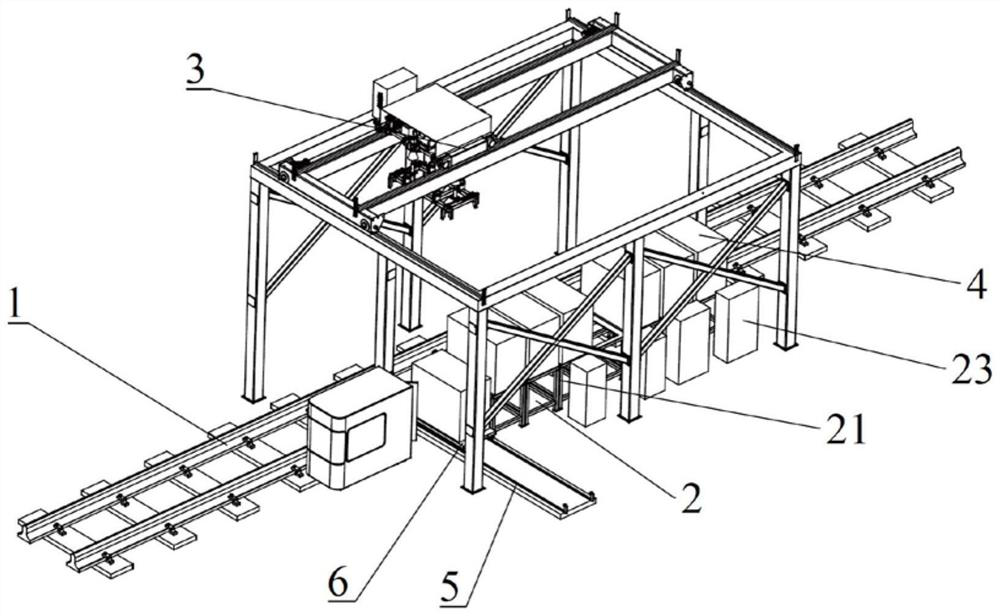

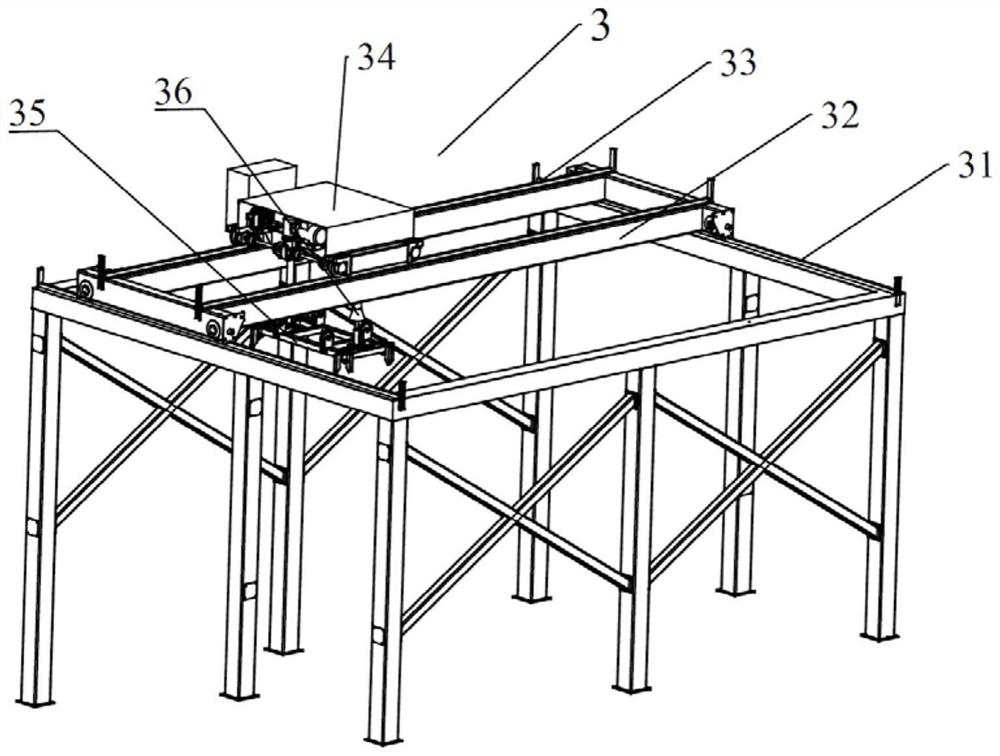

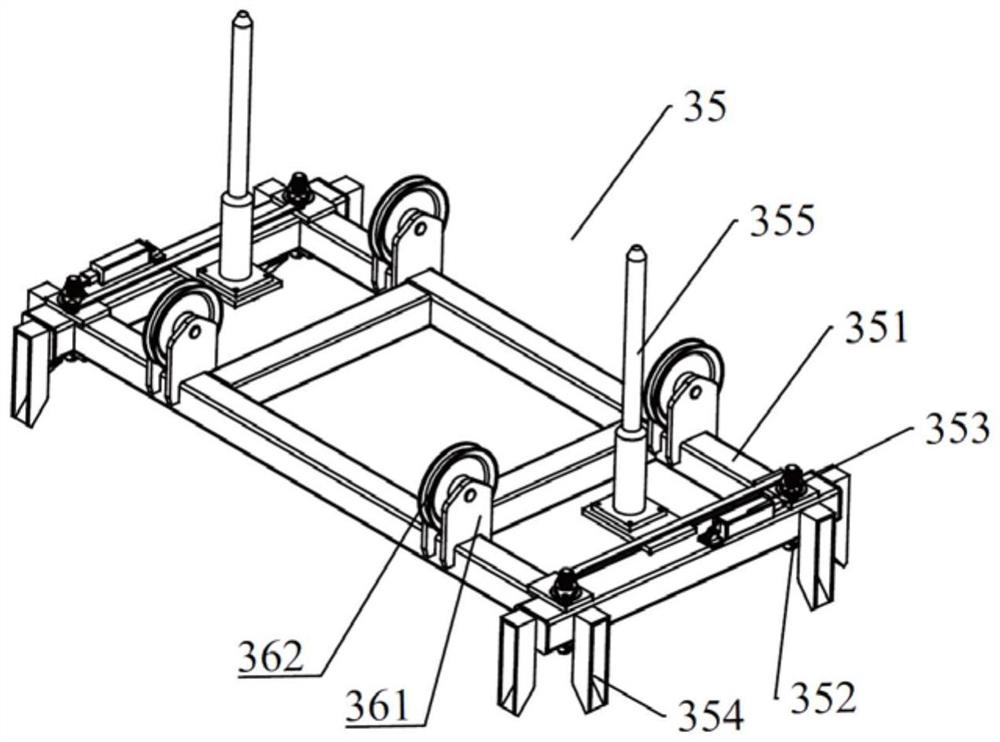

[0062] Such as figure 1 As shown, in one embodiment, the hoisting locomotive power exchange station includes a driving track 1, a battery placement area 2 and a power exchange device 3; the driving track 1 is used for locomotive walking and staying; Side side; including six replacement battery boxes 4, the replacement battery box 4 is used to replace the battery box to be replaced of the locomotive; the power exchange equipment 3 is arranged above the battery placement area 2 and the driving track, and is used to remove the battery to be replaced of the locomotive The box is transferred to the locomotive and outside the running track, and the replacement battery box 4 is grabbed and put into the locomotive.

[0063] The battery placement area 2 can be a charging area for charging the replacement battery box 4 , or a transfer placement area that does not have the function of charging the replacement battery box 4 .

[0064] Such as figure 1 As shown, in another embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com