Automatically adjustable imager

An automatic adjustment, imager technology, applied in the field of imager, can solve the problems of insufficient dust protection, low work efficiency, insufficient clamping, etc., and achieve the effect of improving the efficiency of observation and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

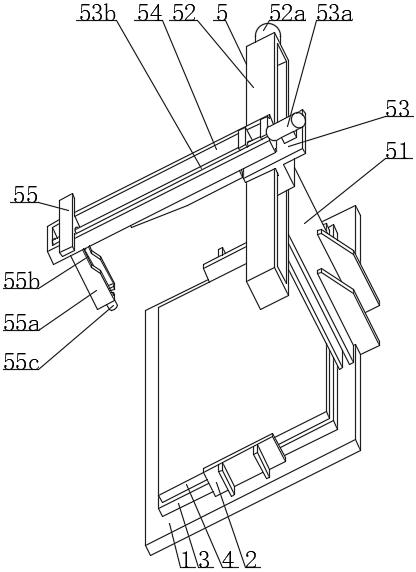

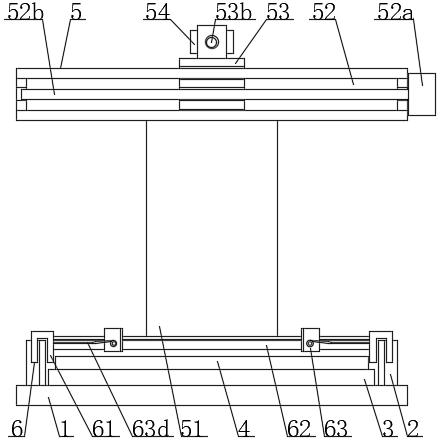

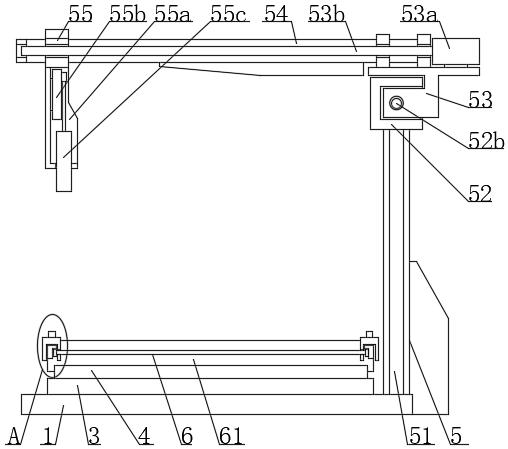

[0033] refer to Figure 1-7 , an automatically adjustable imager, comprising a base 1, the opposite sides of the base 1 are fixedly connected with baffles 2, the top of the base 1 is clamped with a marble table 3, and the top of the marble table 3 is fixedly connected with a loading The object table 4 is fixedly connected with the observation mechanism 5 at the rear end of the base 1 , and the positioning mechanism 6 is clamped at the top of the baffle plate 2 .

[0034] In this example, if figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7 As shown, the observation mechanism 5 includes a bracket 51, the bottom end of the bracket 51 is fixedly connected with the rear end of the base 1, the top end of the bracket 51 is fixedly connected with a mounting frame 52, and the inner side of the mounting frame 52 is slidably connected with a mounting slide 53. The top of the slide seat 53 is fixedly connected with a guide frame 54, and the inner side of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com