Intelligent control device for direct-drive screw pump

An intelligent control and screw pump technology, applied in the direction of pump control, pumps, pump components, etc., can solve the problems of positioning structure installation environment exposure, inconvenient use, easy to lose, etc., to achieve easy location search, increase the probability of damage, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

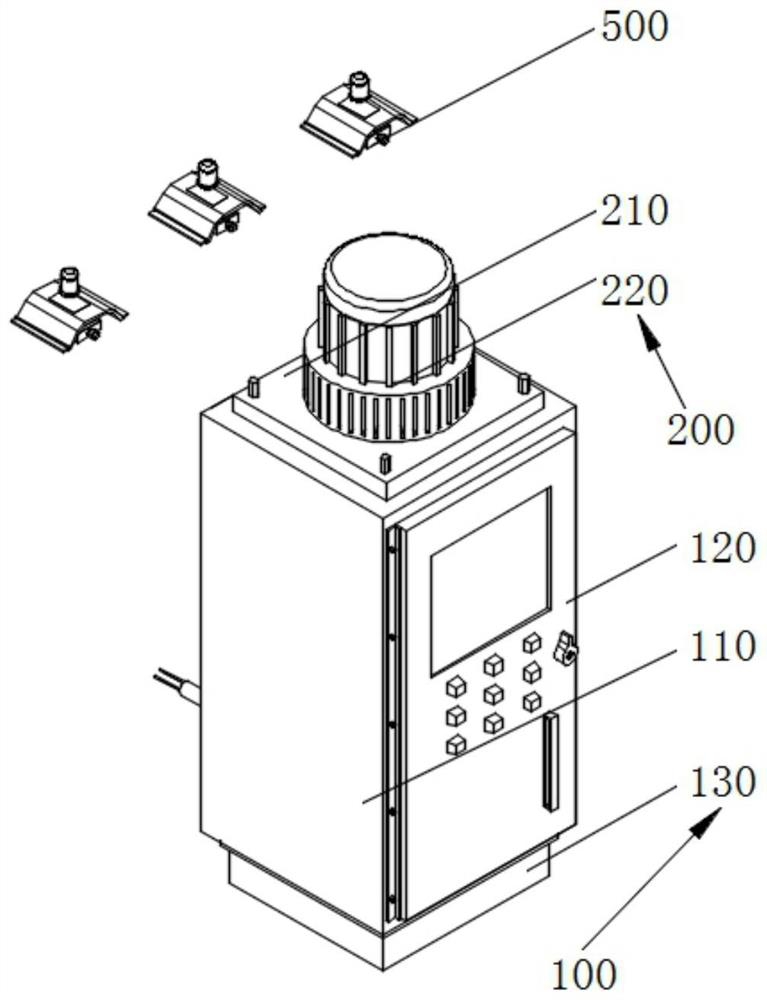

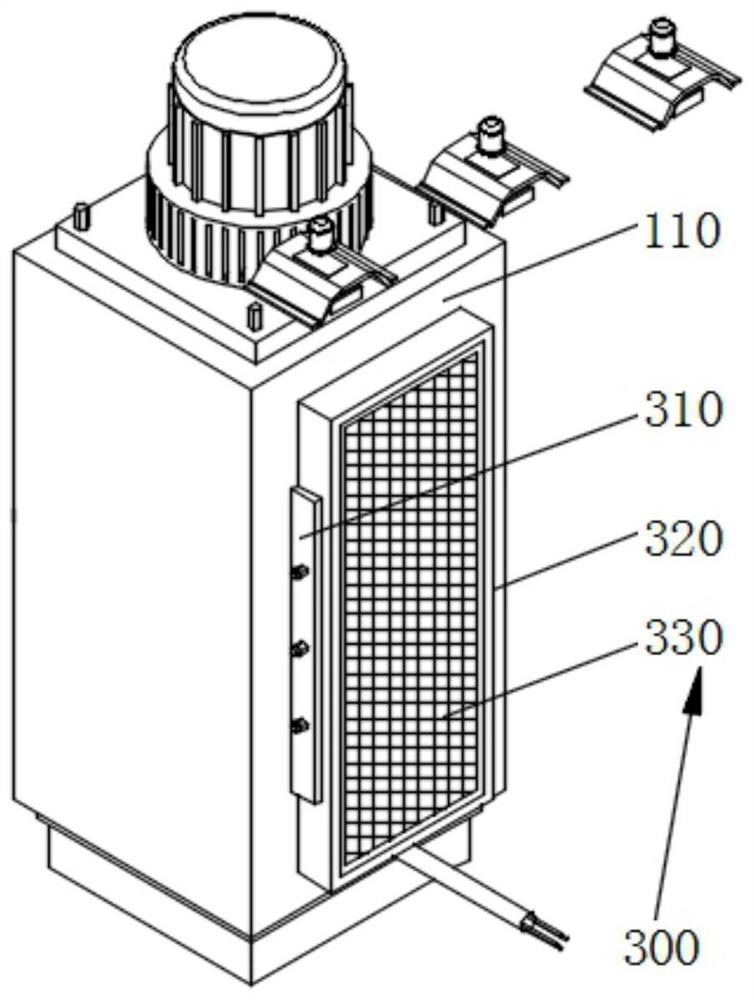

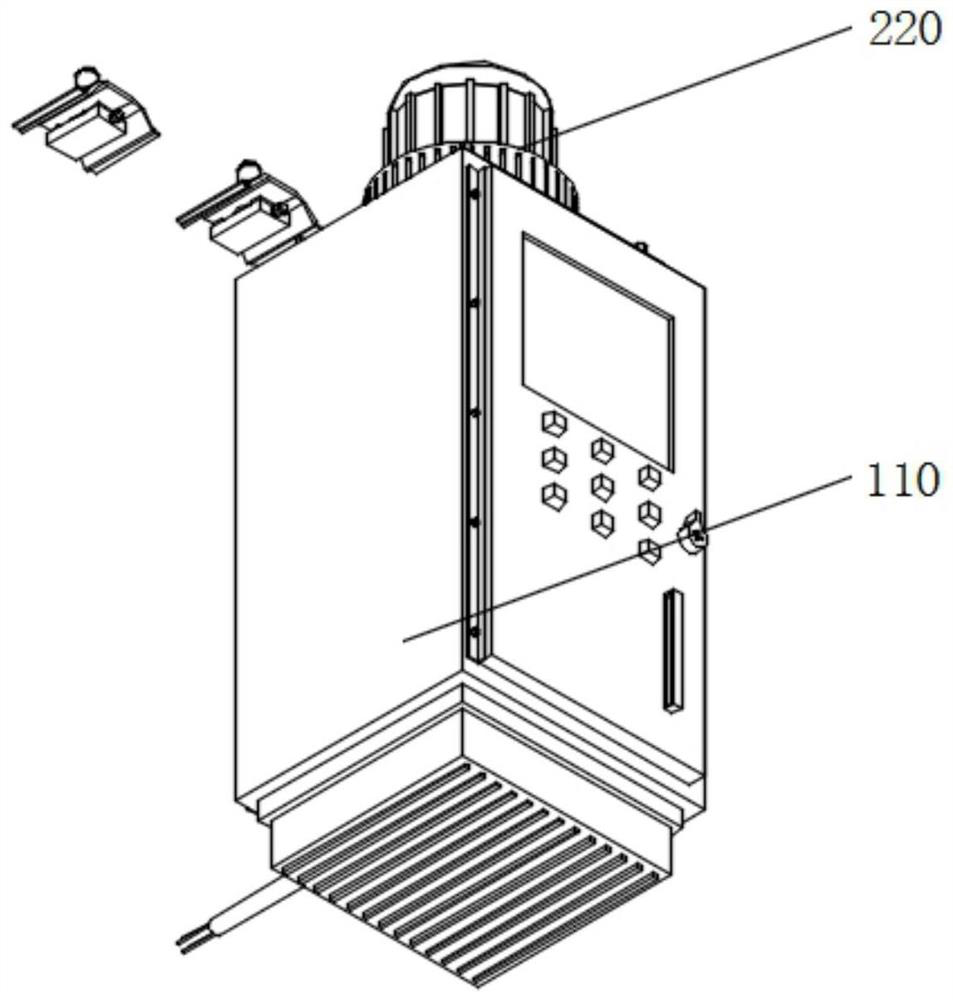

[0038] see Figure 1-6 As shown, the present invention is an intelligent control device for a direct drive screw pump, comprising:

[0039] Control box 100, the central position of the upper end surface of the control box 100 is connected with a cooling mechanism 200, and the central position of the rear end surface of the control box 100 is connected with an isolation mechanism 300. A control module 400 is slidingly connected in the middle of the box 100;

[0040] For the overall use of the device, after the control box 100 is placed at the designated position, the contact between the anti-skid groove and the ground ensures the stability of its structure. At this time, the control module 400 operates to control the direct drive screw pump, and the control box 100 During use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com