Concrete pavement maintenance equipment

A technology for concrete pavement and equipment, which is applied in the direction of pavement cleaning, roads, roads, etc., can solve the problems of time-consuming and laborious concrete pavement maintenance, lifting of the heat preservation and moisturizing layer, and cumbersome process, so as to improve the efficiency of pavement maintenance, reduce maintenance costs, and avoid tediousness The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

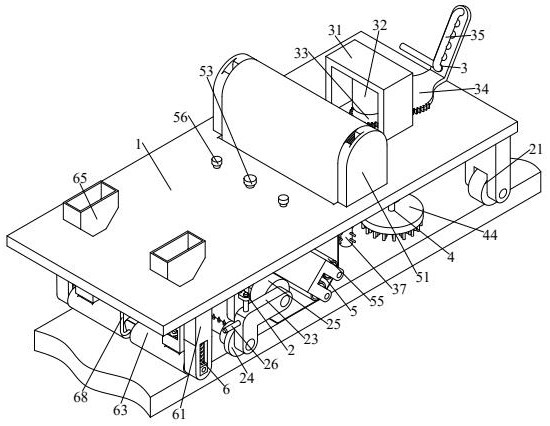

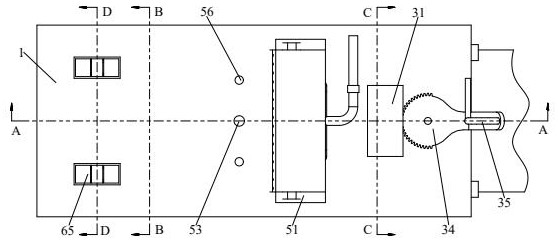

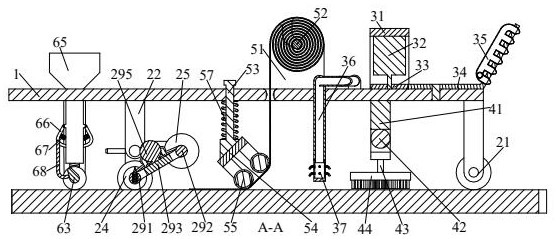

[0033] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0034] refer to figure 1 and figure 2 , a concrete pavement maintenance equipment, including a mounting plate 1, a moving device 2, a sprinkler 3, a cleaning device 4, a laying device 5 and a pressing device 6, the lower end of the mounting plate 1 is equipped with a moving device 2, and the right side of the mounting plate 1 A sprinkler 3 is installed on the side, and a cleaning device 4 is arranged inside the sprinkler 3, and the cleaning device 4 is installed on the right side of the lower end of the installation plate 1, and a laying device 5 is installed in the middle of the lower end of the installation plate 1, and a compacting device 5 is installed on the left side of the laying device 5. Device 6, pressing device 6 is installed on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com