Hanging lug type mounting and supporting mechanism of ram air turbine system

A technology of turbine system and ram air, which is applied to gas turbine power plant, power plant type, power plant construction, etc., can solve the problems of RAT support structure size, poor RAT support stability, large external size, etc. Reliability, the effect of increasing support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

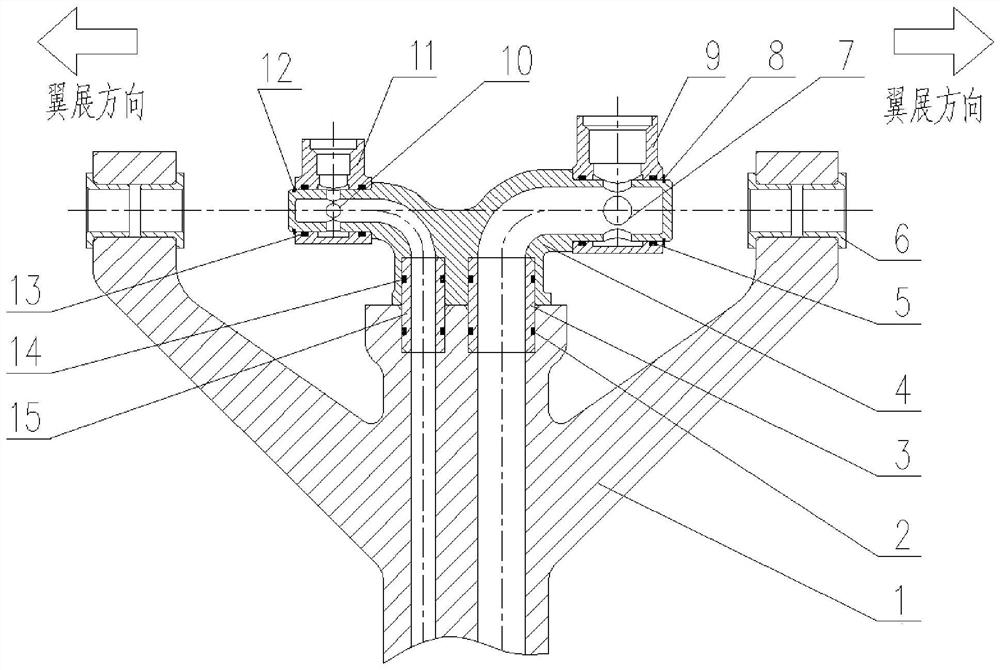

[0027] Example 1. An ear-mounted support mechanism for a ram air turbine system, consisting of Figure 1-2 As shown, it includes a support arm, an adapter seat and a sealing structure. A fork-shaped structure is derived from the upper end of the RAT support arm, and a hole structure is set at the fork-shaped structure as the installation interface between the RAT and the aircraft. At the same time, the support arm and the adapter seat are provided with mutually independent high-pressure oil circuit and low-pressure oil circuit. The high and low pressure oil circuits of the support arm are connected.

[0028] High and low pressure intubations are arranged between the adapter base and the support arm for connecting the high and low pressure oil circuits between the support arm and the adapter base.

[0029] There are high and low pressure mounting seats on the outside of the oil circuit on both sides of the adapter seat, which are used to connect with the hydraulic oil circui...

Embodiment 2

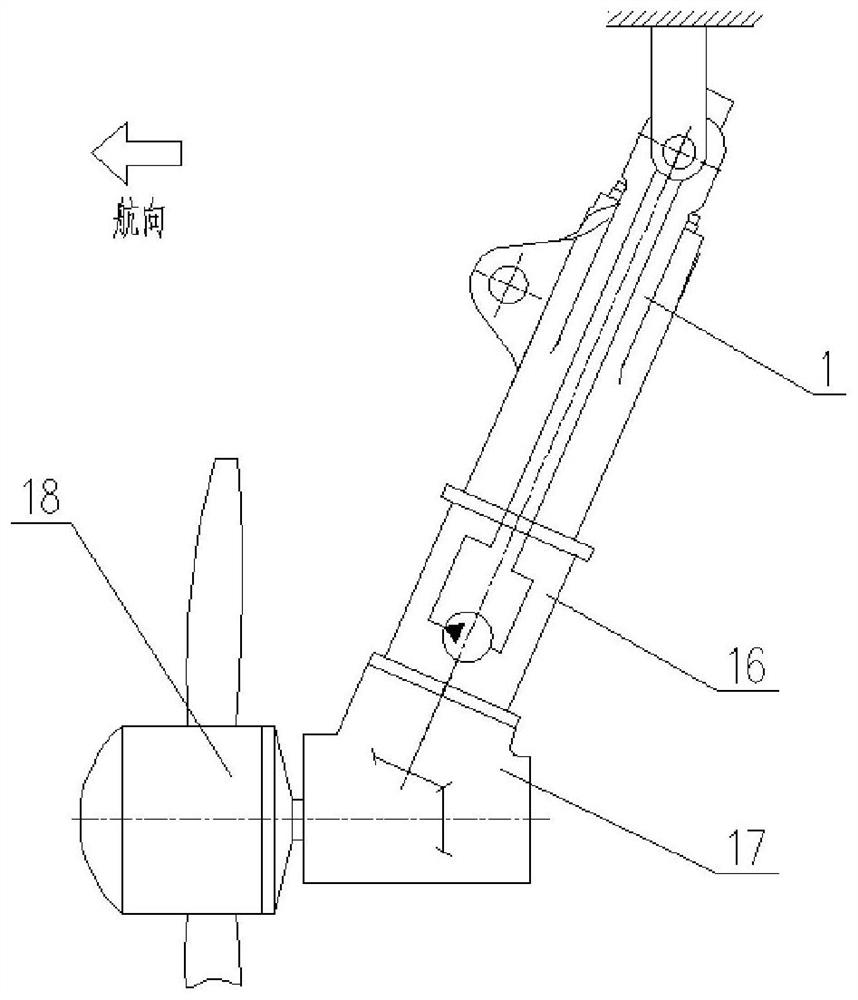

[0035] Example 2. A ram air turbine system lug mount support mechanism, see figure 1 , The ram air turbine system hanger mounting support mechanism of the present invention includes a support arm 1, an adapter seat 4, a high-pressure intubation tube 15, a low-pressure intubation tube 3, a high-pressure mounting seat 11, a low-pressure mounting seat 9 and other parts. Wherein, a fork-shaped structure is derived from one end of the support arm 1, and a mounting hole is provided at the fork-shaped structure, which is used as a mechanical interface between the RAT and the aircraft.

[0036] When installing the RAT, align the axis of the mounting holes at the mounting lugs with the corresponding holes of the aircraft RAT mounting seat, and then insert the fixing screws to realize the fixing of the RAT. When the RAT is retracted, the RAT rotates around the axis of the mounting hole of the mounting ear to realize the rotation function of the RAT. In order to reduce the friction bet...

Embodiment 3

[0044] Example 3. An ear-mounted support mechanism for a ram air turbine system, consisting of Figure 1-2 As shown, it includes setting support arm 1, adapter seat 4, low-voltage mounting seat 9 and high-voltage mounting seat 11; wherein, the top of the support arm derives a fork-shaped structure, and the RAT mounting holes at the top of the two fork-shaped structures realize The connection with the aircraft structure; the adapter seat 4 is arranged between two forks; the adapter seat 4, the support arm 1, the low-pressure mounting seat 9 and the high-pressure mounting seat 11 are all provided with a low-pressure oil circuit and a high-pressure oil circuit. Connector 4, support arm 1, low-pressure mounting seat 9 and high-pressure mounting seat 11 are correspondingly connected to low and high-pressure oil passages, and adapter seat 4 is also respectively connected to low and high-pressure mounting seats in rotation, and the rotation axis is in line with that of the two forks....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com