A lithium battery linear sensing detection primary disassembly device and method

A linear sensing and lithium battery technology, applied in the direction of shearing devices, battery recycling, shearing machine accessories, etc., can solve a large number of bulging, component extrusion offset, dust pollution and other problems, and achieve the goal of improving the recyclability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

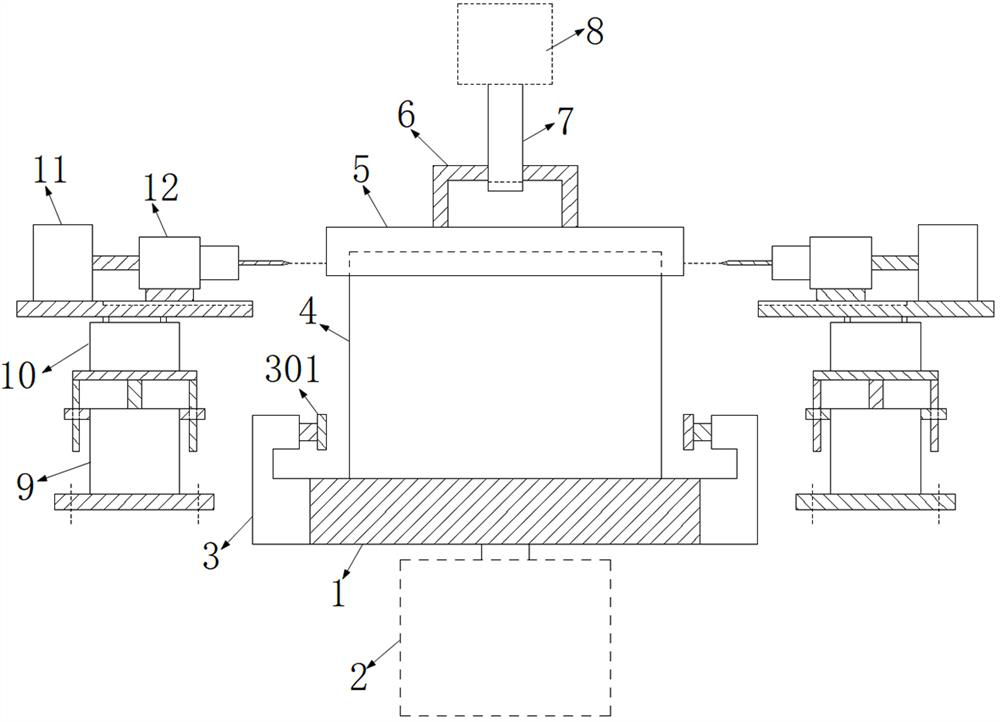

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , after the battery box 4 is placed on the bearing platform 1, the side clamping mechanism 3 is used to drive the clamping push plate 301 to "positive position" the battery box 4. The side clamping mechanism 3 can use a hydraulic device. It is necessary to pay attention to ensure the hydraulic synchronization of the two side clamping mechanisms 3, and ensure that the driving force and the advancing [final] distance of the hydraulically driven clamping and propelling plates 301 on both sides are the same.

[0030] The rotating device 2 below the carrying table 1 can use a servo motor to rotate the carrying table 1 so that the side corresponding to the battery cover 5 faces the cutting piece 22 of the cutting device 12 .

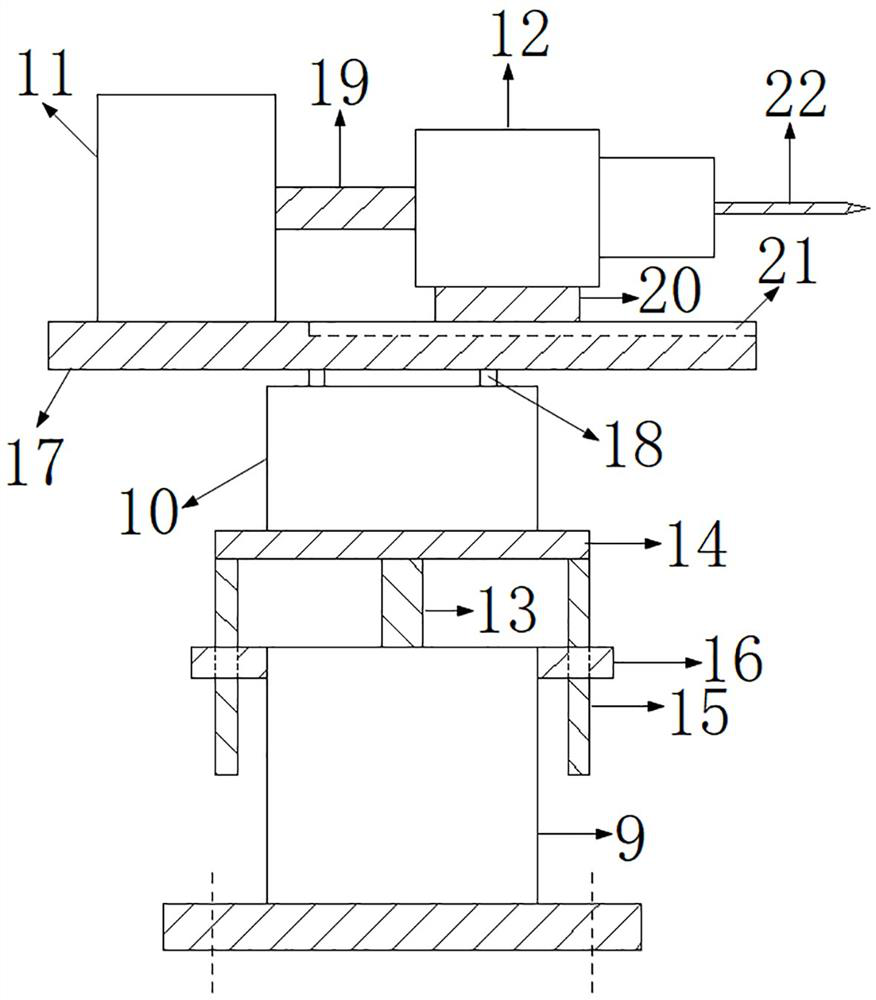

[0031] The lifting device 9 can be fixedly installed on the corresponding base frame. The lifting device 9 is configured with a coding module for sensing and detecting the lifting distance of the lifti...

Embodiment 2

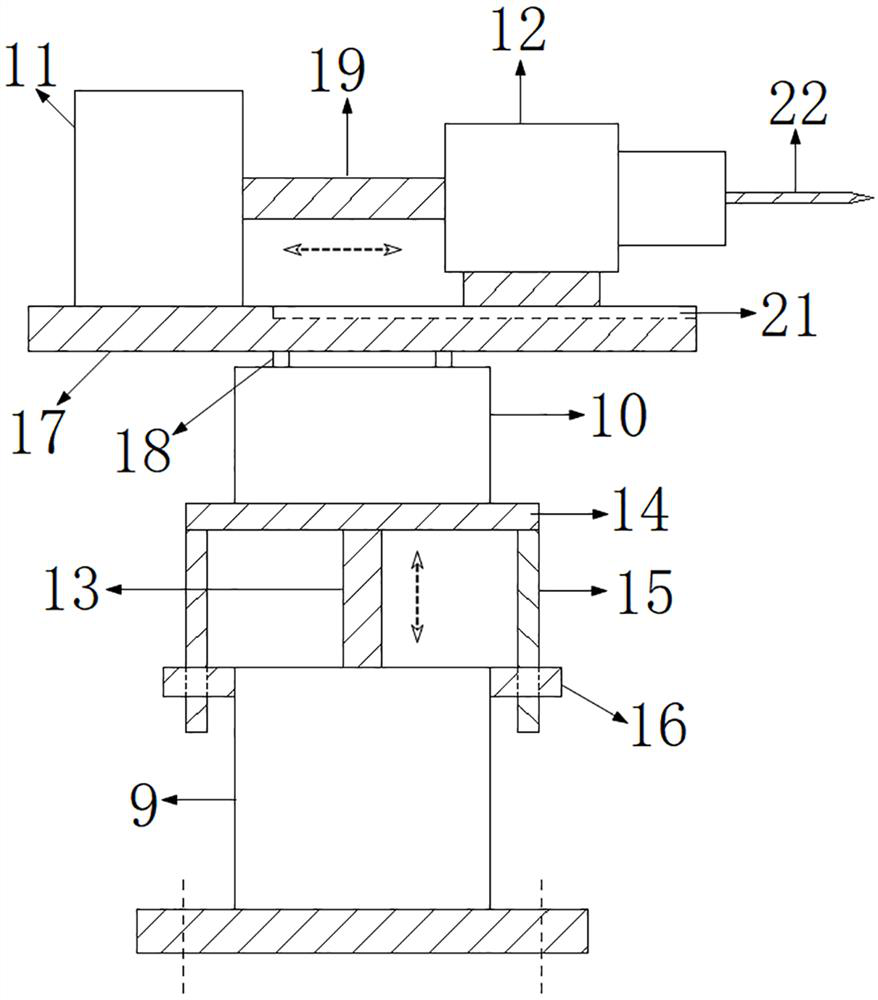

[0035]In the present invention, the specific function meaning of the initial distance: the cutting device 12 moves forward to ensure that the cutting piece 22 of the cutting device 12 is in contact with the outer side of the battery cover 5; moving the initial distance backward, the cutting piece 22 does not contact the battery when turning Cover 5 comes into contact.

[0036] see figure 1 , Figure 5 , when the initial distribution of the cutting device 12 is performed on the periphery of the battery cover 5, the figure 1 A set of pair-side distribution structures in Figure 5 The structure of the adjacent side distribution in the middle.

[0037] use figure 1 In the distribution mode of the middle cutting device 12, the rotating device drives the bearing platform 1 to rotate 90° during each round cutting process, and two parameter values must be set for the initial distance between the two longitudinal moving devices 11 to advance the cutting device 12. The initial...

Embodiment 3

[0041] see figure 1 , figure 2 , image 3 , In the present invention, after completing one cycle of cutting, the lifting mechanism 8 attempts to lift the battery cover 5 once. If the lifting force is too large or the battery cover 5 cannot be lifted under the set lifting force The ring side of the cover 5 has not been completely cut, or the strong sealant layer between the inner side of the battery cover 5 and the battery box 4 has not been cut off. The layer is bonded and cured, and the adhesion is large], sometimes it is necessary to cut to the inner side wall surface of the casing of the battery box 4 to lift the battery cover 5, and then to open the battery cover 5.

[0042] In the present invention, when the lifting mechanism 8 lifts the hook upward, the high stroke position of the hook 7 moving upward is set at a position where the battery cover 5 and the battery box 4 can be separated [after the battery cover 5 and the battery box 4 are cut] . For example, after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com