Continuous ink supply device for printer

A technology for ink supply devices and printers, applied in printing, etc., can solve problems affecting printing progress and output, affecting printing quality, etc., and achieve the effects of improving printing efficiency, convenient operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

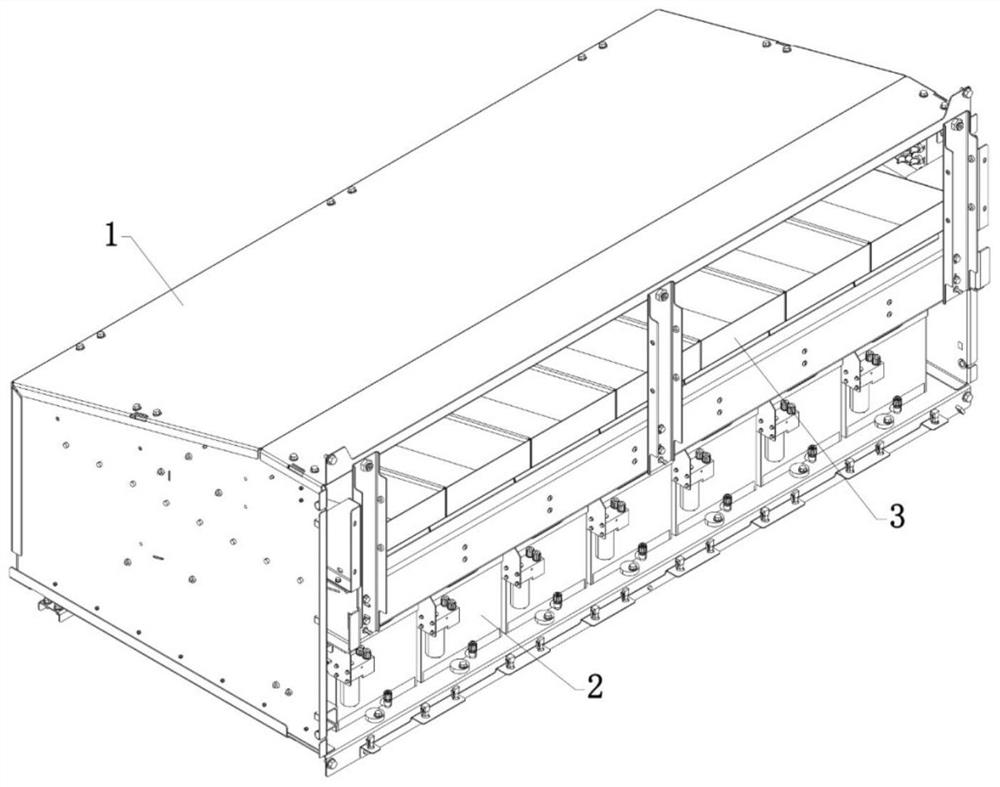

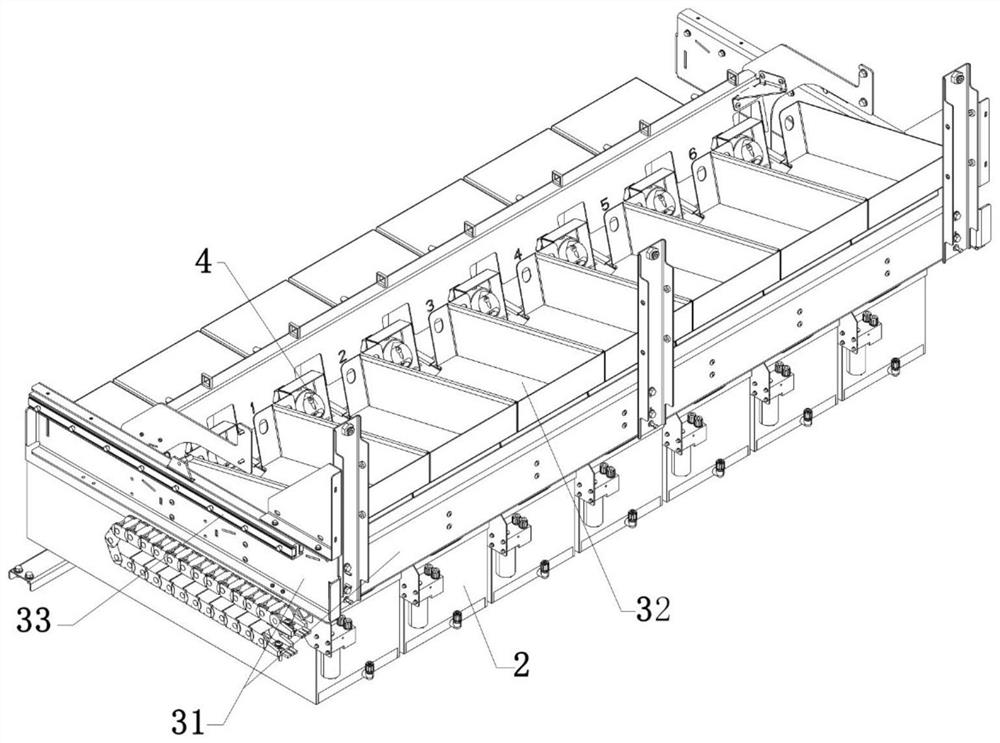

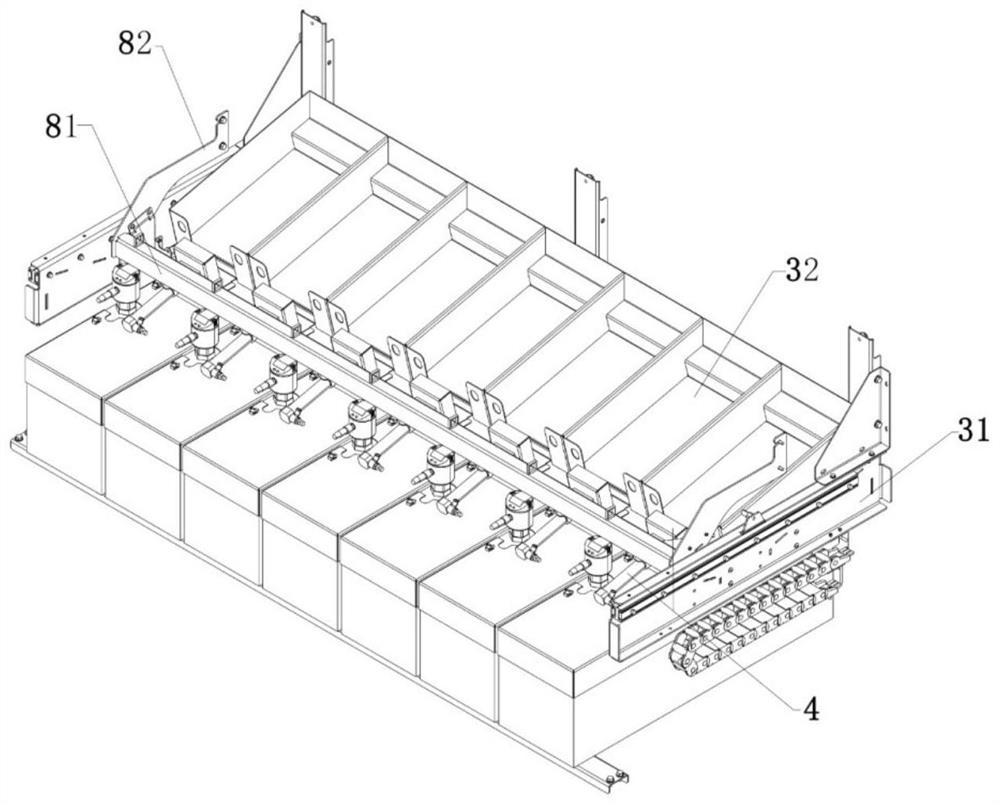

[0032] refer to Figure 1 to Figure 4 As shown, a continuous ink supply device for a printer is improved in that it includes an ink supply tank 1, a main ink tank 2 is provided at the bottom of the ink supply tank 1, and a liquid level is provided in the main ink tank 2. Sensor 23; an ink replenishment device 3 is installed above the main ink tank 2 in the ink supply tank 1, and the ink replenishment device 3 can move back and forth relative to the ink supply tank 1, and the ink replenishment device 3 includes a mounting frame 31, the installation frame 31 is equipped with a storage slot 32 corresponding to the position of the main ink tank 2, and the storage slot 32 is used to place the ink replenishment cartridge, and when the installation frame 31 is moved to the limit position , the position of the ink outlet of the ink replenishment ink cartridge placed on the accommodating tank 32 corresponds to the position of the ink inlet 211 of the main ink tank 2; a hole-breaking de...

Embodiment 2

[0038] On the basis of embodiment 1, with reference to Figure 9 and Figure 10 As shown, the main ink tank 2 includes a tank body 21 and an upper cover 22 that cover each other, the ink inlet 211 is arranged on the upper cover 22, and the lower end of the ink inlet 211 is provided with a chute 2111 .

[0039] Further, the opening direction of the chute 2111 faces away from the liquid level sensor 23 .

[0040] Further, the bottom of the tank body 21 is inclined, and the lower side of the bottom of the tank body 21 is provided with an ink outlet hole 221, and the outer port of the ink outlet hole 211 is provided with an ink outlet joint 24 .

[0041] Further, the bottom of the tank body 21 is provided with a groove 222 communicating with the ink outlet hole 211 , and the upper end of the groove 222 is provided with a filter layer 25 .

[0042]In this embodiment, the setting of the chute 2111 guides the flow of ink, preventing the ink from directly pouring onto the liquid l...

Embodiment 3

[0044] On the basis of embodiment 1 or 2, with reference to Figure 4 and Figure 5 As shown, an ink receiving tank 5 is arranged under the rear side of the accommodating tank 32 , and the ink receiving tank 5 is movably connected with the installation frame 31 and can move back and forth relative to the installation frame 31 .

[0045] Further, the left and right sides of the ink receiving tank 5 are respectively provided with connecting parts, and the ink receiving tank 5 is flexibly connected with the installation frame 31 through the connecting parts, and the connecting parts include The front and rear brackets 61 and rear brackets 62 fixedly connected to the front and rear sides of the groove 5 and the mounting frame 31 are provided with the front bracket 61 and the rear bracket 62 between the front bracket 61 and the rear bracket 62. The connecting column 63 is fixedly connected and passed through the ink receiving tank 5 , and a spring 64 is sleeved on the connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com