Welding-free power supply plug

A technology of plugging and electric energy, which is applied in the direction of electric light sources, circuit layout, lighting devices, etc., to achieve the effects of avoiding material waste, omitting high energy consumption and saving metal solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

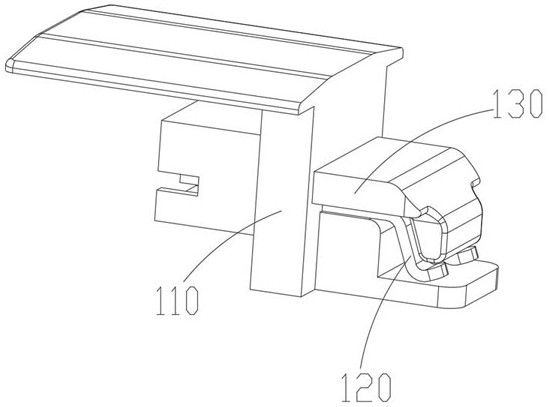

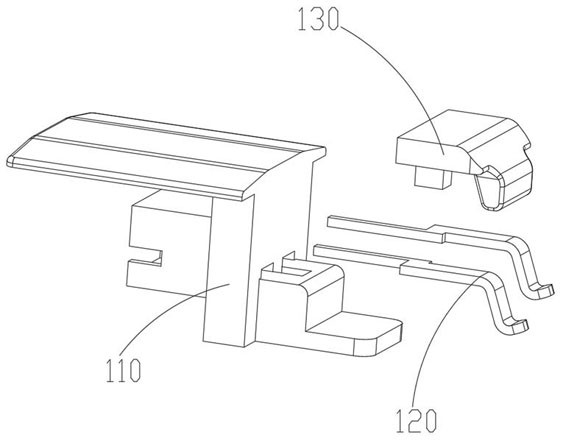

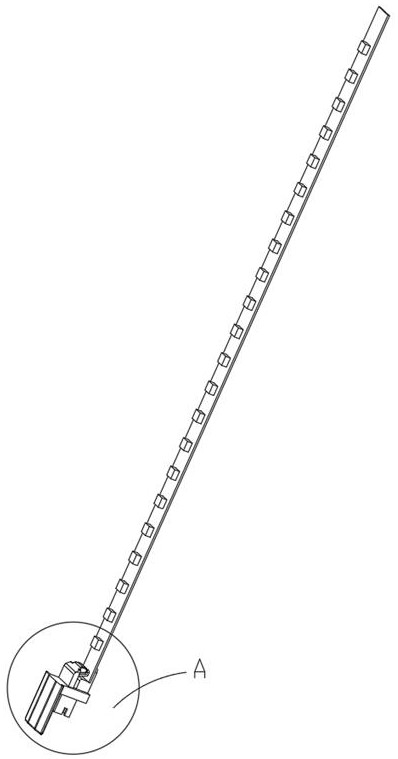

[0021] Such as Figures 1 to 8 As shown, a welding-free power supply plug includes a connecting piece 110, a guide pin 120 and a positioning piece 130, wherein, when in use, the connecting piece 110 is connected to the side end of the lamp, and the inside of the lamp is provided with a light strip 20, The light strip 20 can generate lighting when it is in operation. The side wall 101 of the connector 110 is provided with a number of conductive holes 111 , and the surface of the side wall 101 facing the lamp is provided with a placing platform 200 .

[0022] The placement table 200 is provided with a placement layer 210 and a positioning layer 220 , the positioning layer 220 is higher than the placement layer 210 , and one end of the light strip 20 is set on the surface of the placement layer 210 during use.

[0023] The positioning layer 220 is provided with a positioning groove 221 facing downward, and the conductive hole 111 is disposed at a side end of the positioning layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com