A fixed-distance automatic plate cutting device

A cutting device and fixed-distance technology, which is applied in the field of automatic fixed-distance plate cutting devices, can solve the problems of excessive cutting of plates, unusable plates, etc., and achieves the effect of increasing the degree of automation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

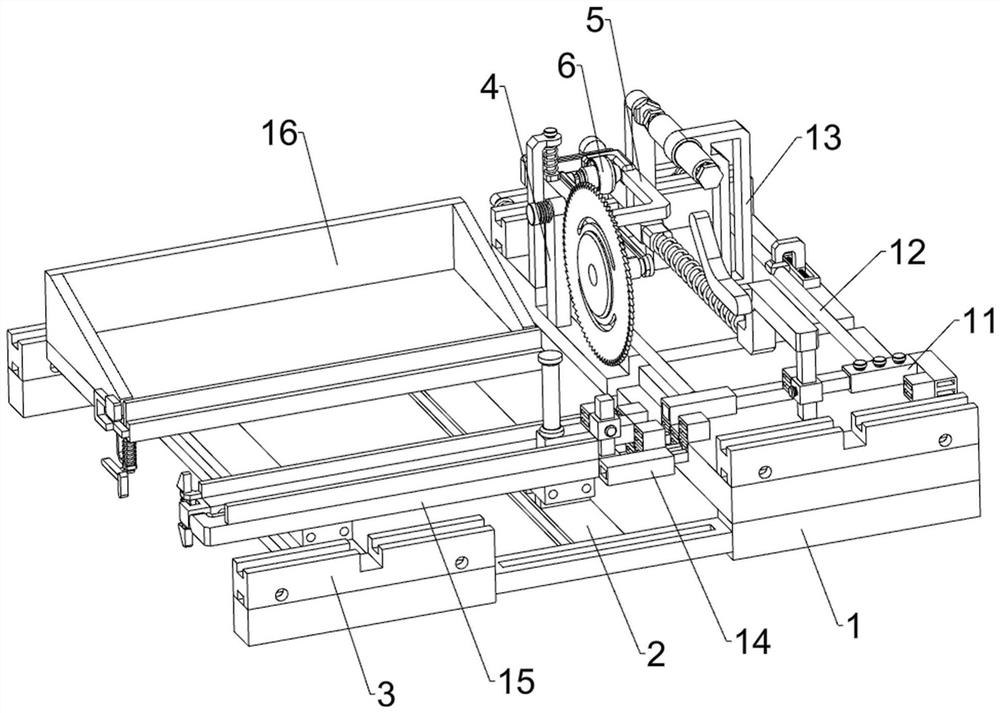

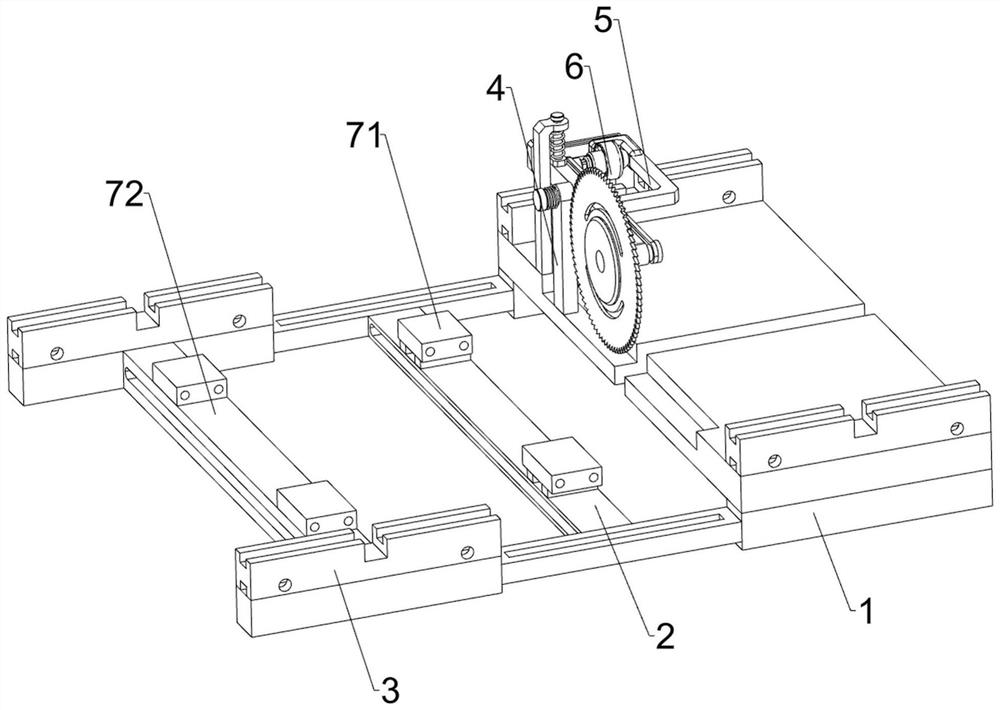

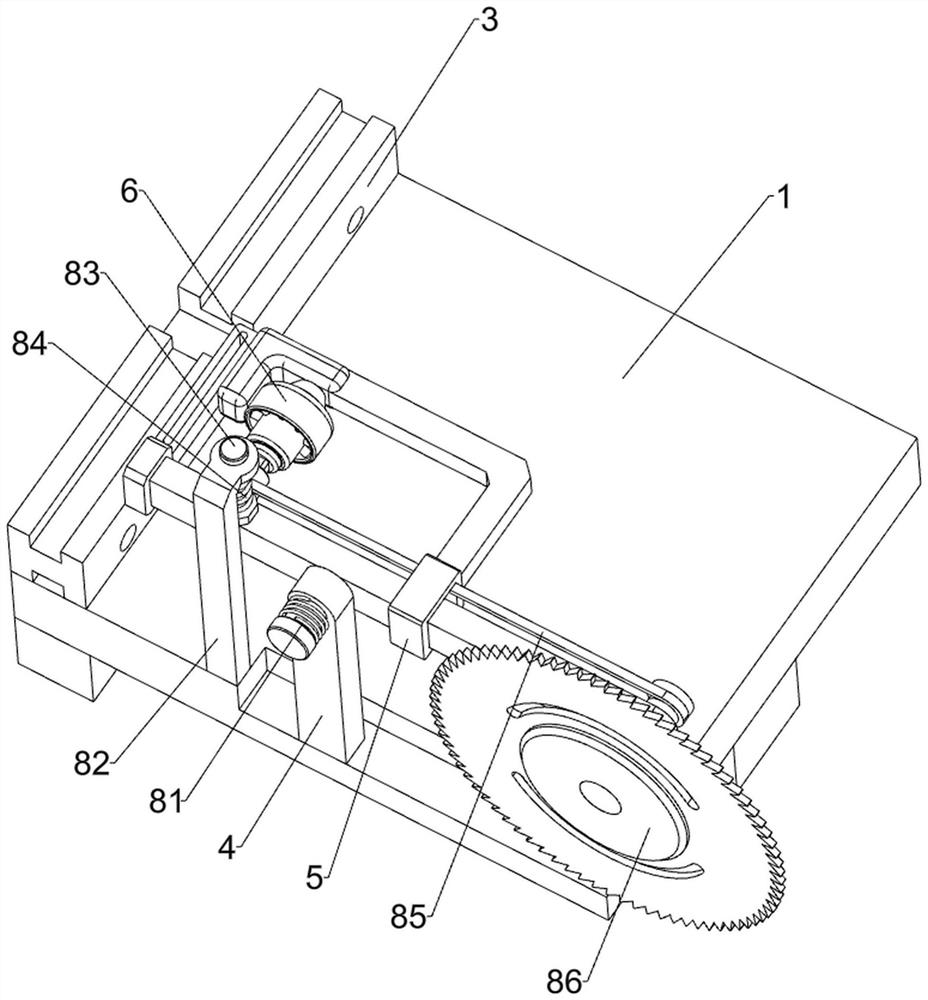

[0036] A fixed-distance automatic plate cutting device, refer to Figure 1-9 As shown, it includes a mounting frame 1, a connecting frame 2, a guide plate 3, a mounting plate 4, a stabilizer frame 5, a servo motor 6, a support block 71, a support plate 72, a first spring 81, a buffer frame 82, a buffer rod 83, The second spring 84, the belt 85, the cutting wheel 86, the spacing mechanism 11, the adjusting mechanism 12 and the pressing mechanism 13, the right side of the connecting frame 2 is symmetrically provided with the mounting frame 1 by welding, and the top of the rear side mounting frame 1 is on the left side. The mounting plate 4 is provided on the side by welding, the upper side of the mounting plate 4 is rotatably provided with a stabilizer frame 5, the rear side of the stabilizer frame 5 is provided with a servo motor 6, and the top right side of the connecting frame 2 is symmetrically provided with supports by welding. Block 71, the left side of the connecting fram...

Embodiment 2

[0042] On the basis of Example 1, refer to figure 1 and Figure 10 As shown, an anti-jam mechanism 14 is also included, and the anti-jam mechanism 14 further limits the plate. The anti-jam mechanism 14 includes an anti-jam plate 141, a splicing block 142, a third sliding rod 143, an anti-jam rod 144 and a third Three screws 145, the lower part of the front side of the second support block 117 is provided with an anti-jamming plate 141 by welding, the left part of the rear side of the anti-jam plate 141 is provided with a splicing block 142 by welding, and the front side of the top of the splicing block 142 is welded There is a third sliding rod 143, the third sliding rod 143 is slidably provided with an anti-jam rod 144, the anti-jam rod 144 can further limit the plate, and the front side of the anti-jam rod 144 is threaded with a third screw 145.

[0043]When placing the board, the staff can first turn the third screw 145 away from the anti-jam rod 144, so that the anti-jam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com