Bow and arrow automatic recovery and treatment device

An automatic recycling, bow and arrow technology, applied in the direction of transportation and packaging, chemical instruments and methods, solid waste removal, etc., can solve the problems of slow speed, time-consuming and labor-intensive, etc., to improve the recycling processing speed, reduce labor costs, realize The effect of automatic recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

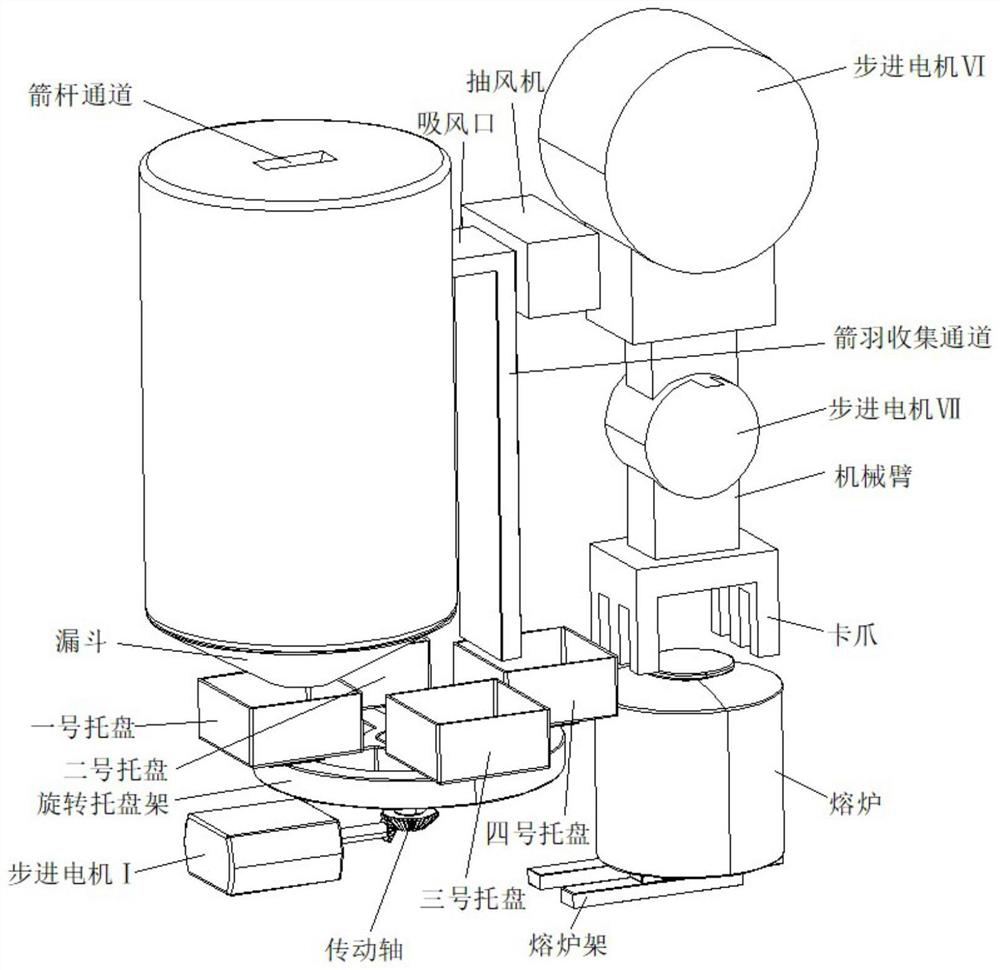

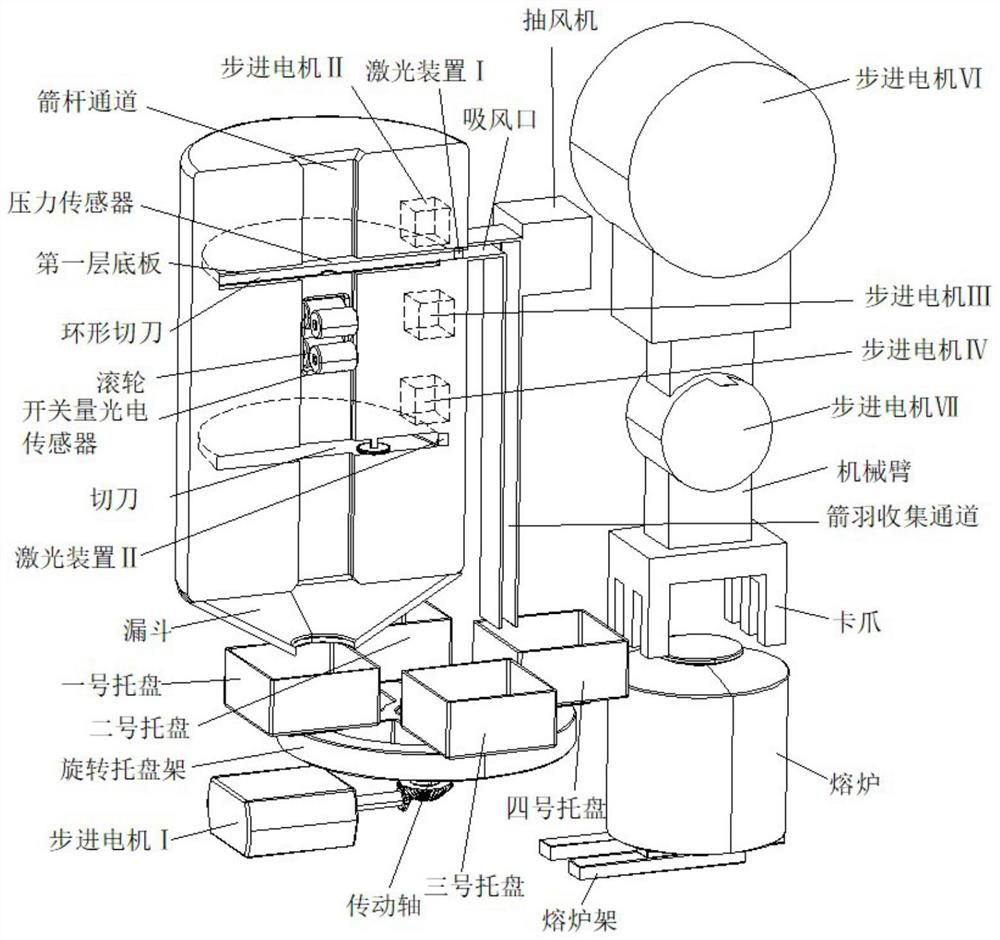

Embodiment 1

[0037] In this embodiment, the control system of the device uses an STM32 processor to control the recycling process of the arrow shaft, and uses a stepping motor and a cutter as mechanical mechanisms to execute control commands. The STM32 processor has a fast calculation speed and adopts the ARM architecture. It can effectively reduce power consumption and have stable performance while having 8 independent timers. At the same time, the motor part, the control end motor uses a stepping motor, which can ensure the accuracy of the knife; and the cutter part uses a high-speed motor to ensure cutting efficiency. The part collected at the bottom is in the form of a rotating disc, and multiple trays are placed on the rotating tray rack to hold the cut materials separately. The trays are connected to the rotating tray rack by buckles. The No. 1 tray is used to recover the fletching, the No. 2 tray is used to recover the nock, the No. 3 tray is used to recover the arrowhead, and the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com