Stator assembly and motor

A component and stator technology, applied in the direction of electric components, windings, electrical components, etc., can solve the problems of limiting motor performance and uneven distribution of heat generation, and achieve the effect of balancing heat generation and heat dissipation, and reducing loss density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

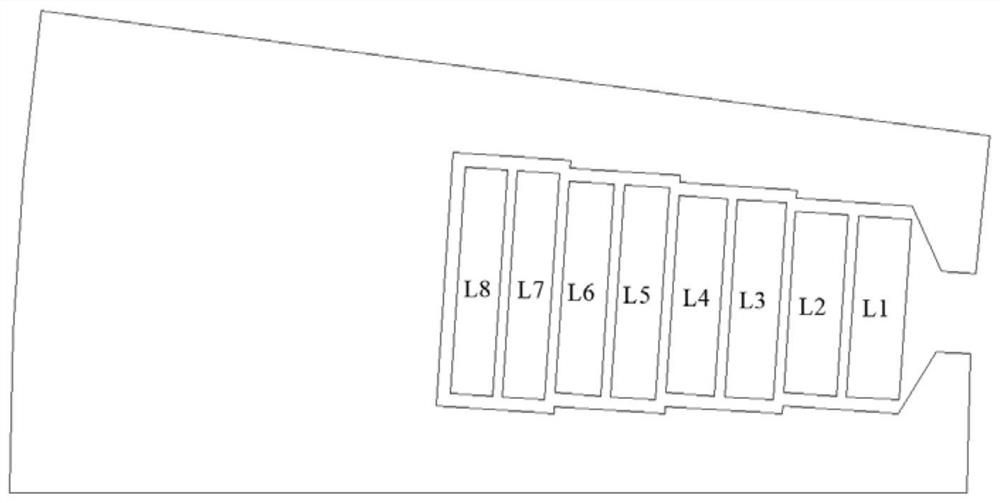

[0059] Such as image 3 As shown, in the technical solution provided by this embodiment, the stator slots are also stepped slots, each stator slot is composed of 4 connected rectangular slots, and each stator slot is provided with 8 layers of rectangular conductors. The rectangular slots of each stator slot are named C1, C2, C3, and C4 in turn. Among them, the rectangular slot C1 is located at the slot opening and belongs to the rectangular slot closest to the center of the iron core in the slot; the rectangular slot C4 is located at the bottom of the slot and belongs to the closest slot in the slot. A rectangular slot in the outer circle of the core. The rectangular conductors in each stator slot are named L1, L2, L3, L4, L5, L6, L7, and L8 in turn, where the L1 conductor is located at the slot opening and belongs to the innermost conductor in the slot near the center of the iron core; the L8 conductor is located at The bottom of the slot belongs to the outermost conductor i...

Embodiment 2

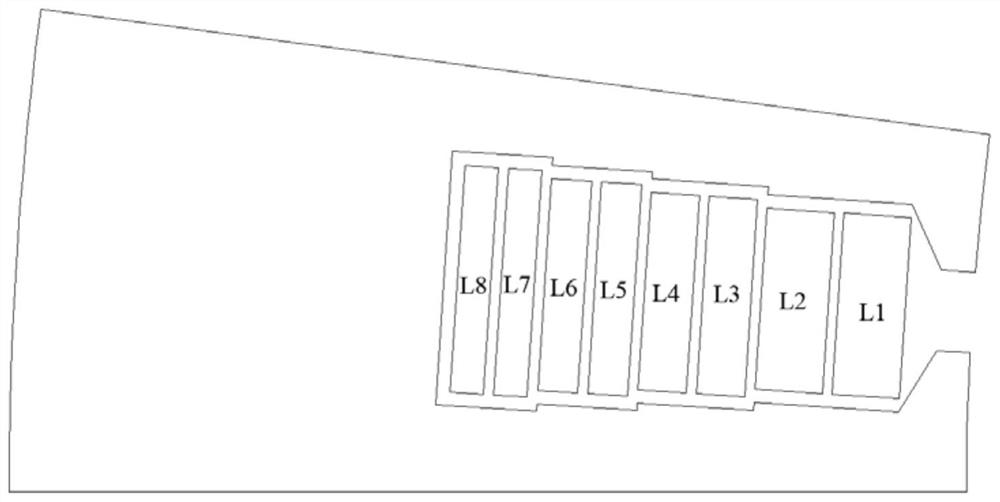

[0066] Such as Figure 5 As shown, in the technical solution provided by this embodiment, the stator slots are also stepped slots, each stator slot is composed of 4 connected rectangular slots, and each stator slot is provided with 8 layers of rectangular conductors. The rectangular slots of each stator slot are named C1, C2, C3, and C4 in turn. Among them, the rectangular slot C1 is located at the slot opening and belongs to the rectangular slot closest to the center of the iron core in the slot; the rectangular slot C4 is located at the bottom of the slot and belongs to the closest slot in the slot. A rectangular slot in the outer circle of the core. The rectangular conductors in the same stator slot are named L1, L2, L3, L4, L5, L6, L7, and L8 in turn. The L1 conductor is located at the slot opening and belongs to the innermost conductor in the slot near the center of the iron core; the L8 conductor is located at The bottom of the slot belongs to the outermost conductor in...

Embodiment 3

[0074] Such as Figure 7As shown, in the technical solution provided by this embodiment, the stator slots are also stepped slots, each stator slot is composed of 4 connected rectangular slots, and each stator slot is provided with 8 layers of rectangular conductors. The rectangular slots of each stator slot are named C1, C2, C3, and C4 in turn. Among them, the rectangular slot C1 is located at the slot opening and belongs to the rectangular slot closest to the center of the iron core in the slot; the rectangular slot C4 is located at the bottom of the slot and belongs to the closest slot in the slot. A rectangular slot in the outer circle of the core. The rectangular conductors in the stator slot are named L1, L2, L3, L4, L5, L6, L7, and L8 in turn. The L1 conductor is located at the slot opening and belongs to the innermost conductor in the slot near the center of the iron core; the L8 conductor is located in the slot Bottom, which belongs to the outermost conductor in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com