Robot positioning calibration charging device

A robot positioning and charging device technology, applied in circuit devices, battery circuit devices, coupling devices, etc., can solve the problems of charging column wear and inaccurate positioning, and achieve the effects of avoiding wear, accurate connection, and delaying connection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

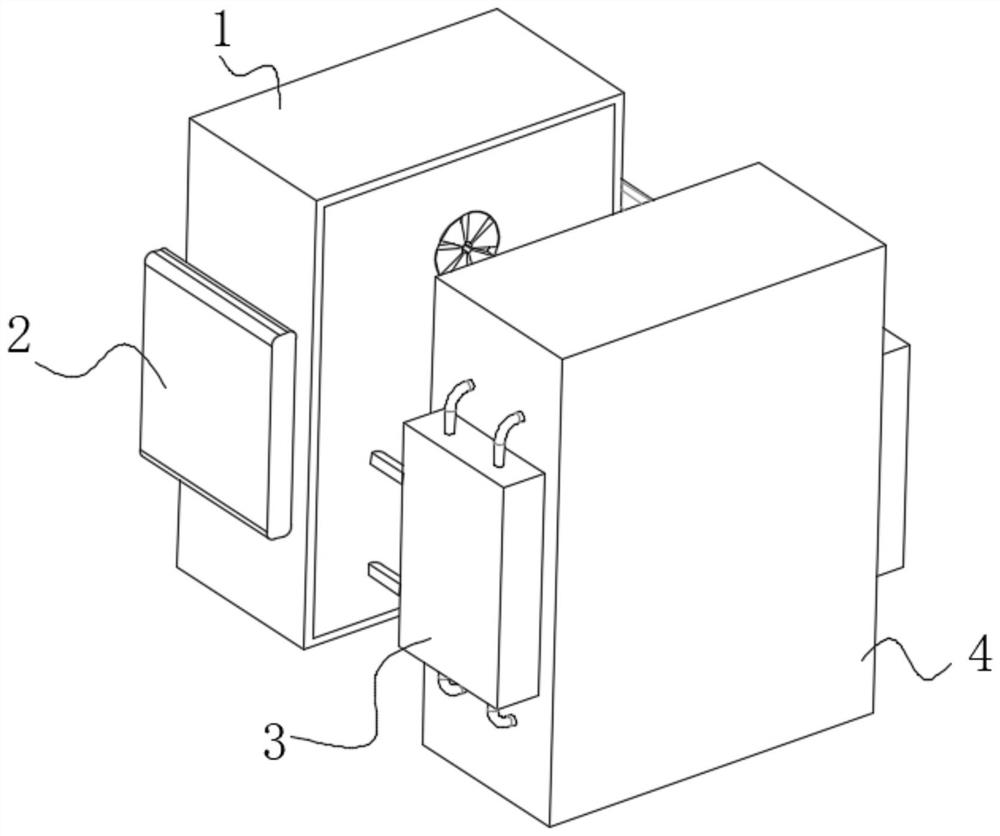

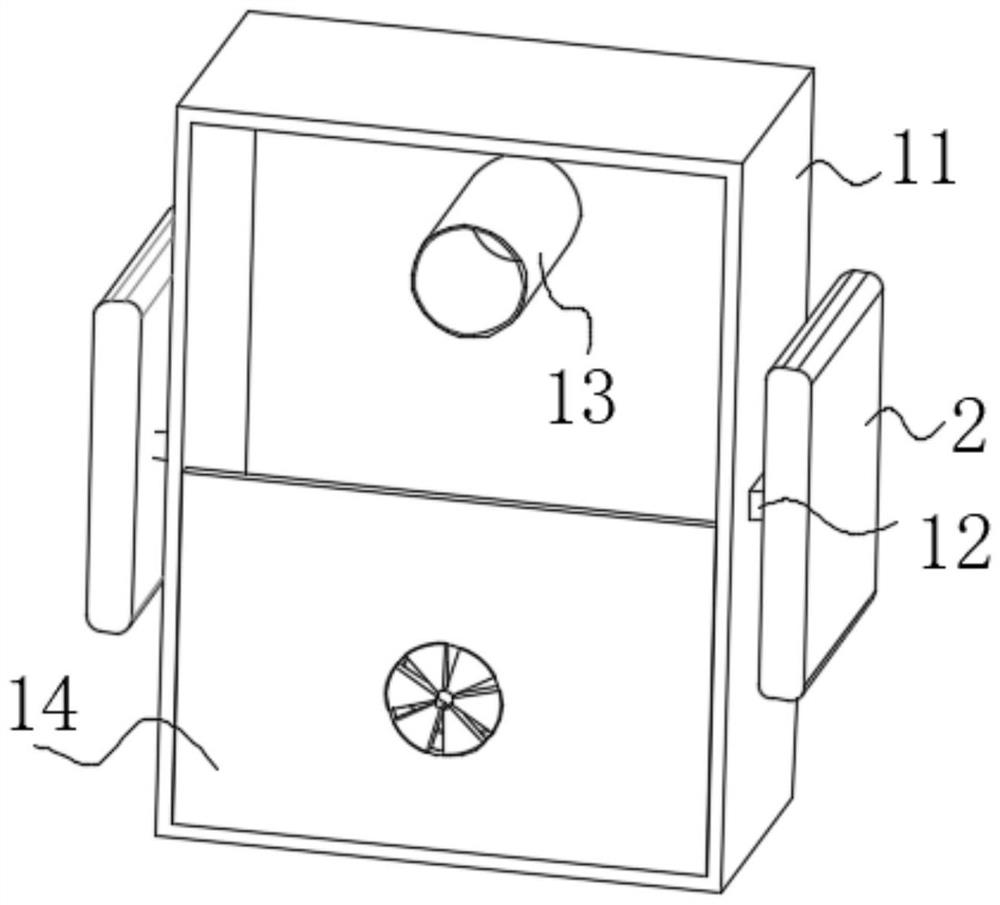

[0023] use Figure 1-Figure 6 A charging device for positioning and calibrating a robot according to an embodiment of the present invention is described as follows.

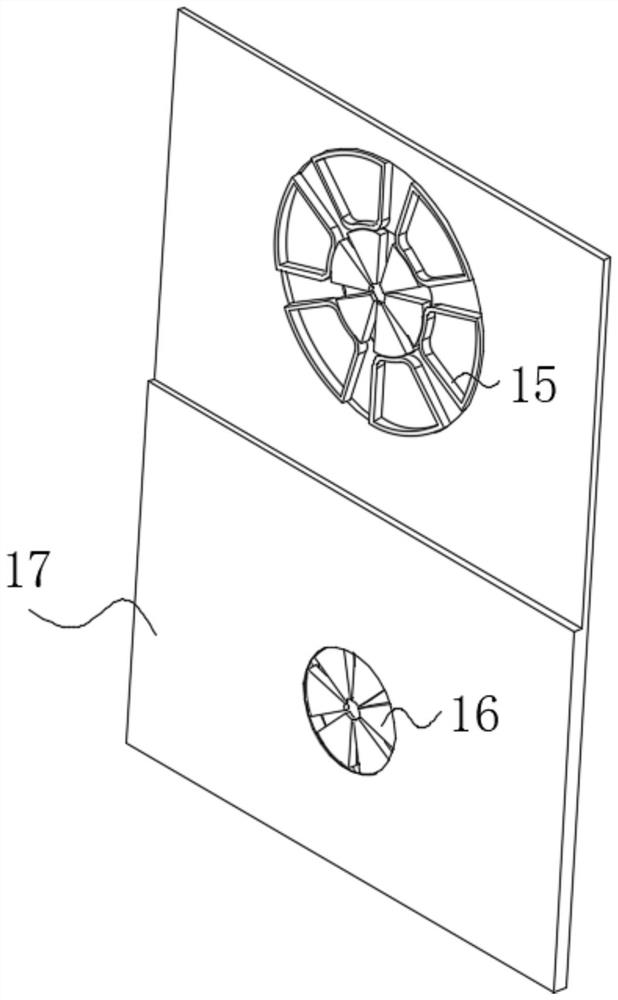

[0024] Such as Figure 1-Figure 6 As shown, a robot positioning calibration charging device according to the present invention includes a connecting block 1; The right end is fixedly connected, the front of the snap-in block 2 is provided with a charging block 4, the two ends of the charging block 4 are symmetrically provided with a snap-in slot 3, and the left end of the charging block 4 is fixedly connected with the right end of the snap-in slot 3, and the snap-in slot is set The purpose of 3 is to reduce the wear efficiency of this kind of robot positioning calibration charging device.

[0025] The charging block 1 includes a main body 11. A charging tank 13 is symmetrically arranged inside the main body 11, and the inner wall of the main body 11 is fixedly connected with the bottom of the charging tank 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com