LED support manufacturing method, LED support, packaging structure and backlight module

A technology for LED brackets and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of short distance of light guide plates, high requirements for light alignment, and small LED luminous angles, so as to increase LED luminous angles and reduce The number of LEDs used and the effect of increasing the side light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a method for manufacturing an LED bracket, which includes the following steps:

[0034] S1. Form a white plastic material layer above the metal layer electrodes; the white plastic material layer can be formed by injection molding or molding process.

[0035] S2. Before the white plastic layer is solidified and formed, spaces are reserved on the tops of the two opposite sides; the shape of the spaces is a cuboid.

[0036] S3. Use a high-precision glue dispenser to place transparent or translucent silicone on the empty space.

[0037] S4, drying silica gel.

[0038] Specifically, in step S2, the height reserved for the vacancy is greater than 1 / 6 of the complete height of the white plastic material layer, or equal to 1 / 6 of the complete height of the white plastic material layer.

Embodiment 2

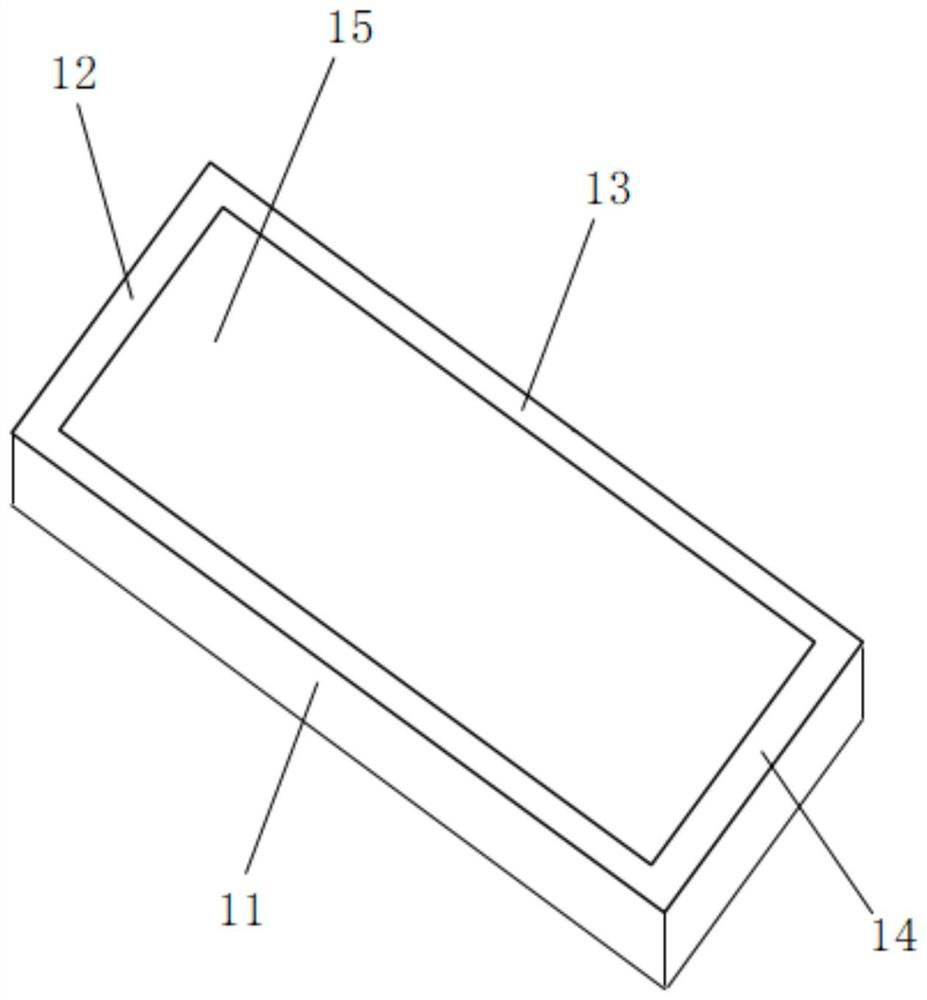

[0040] Such as figure 1 , this embodiment discloses an LED bracket, which is manufactured by using the LED bracket manufacturing method described in Embodiment 1, and includes a metal layer electrode and a bracket body, and the bracket body includes two opposite first side plates 11, 13 and two Two opposite second side plates 12 , 14 , two opposite first side plates 11 , 13 and two opposite second side plates 12 , 14 are connected to form an accommodating cavity 15 .

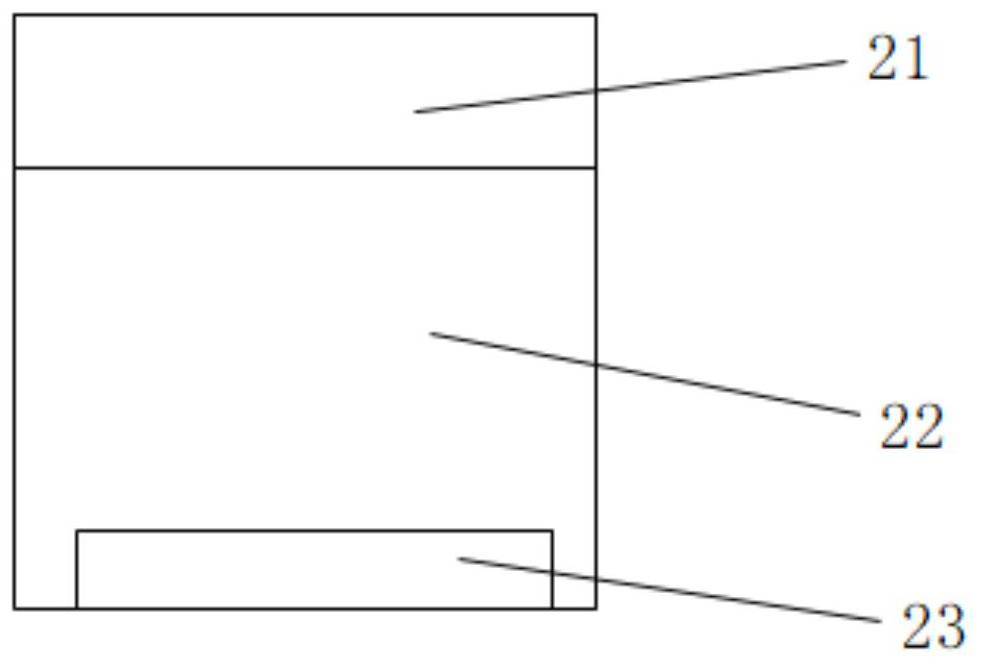

[0041] The first side panels 11, 13 are made of opaque materials, such as figure 2 , the second side plates 12, 14 include a transparent material layer 21 and an opaque material layer 22, the transparent material layer 21 is arranged on the opaque material layer 22, and the bottom of the opaque material layer 22 is provided with a metal layer electrode 23.

[0042] Specifically, the height of the transparent material layer 21 is greater than 1 / 6 of the depth of the accommodating cavity 15 , or equal to 1 / 6 of ...

Embodiment 3

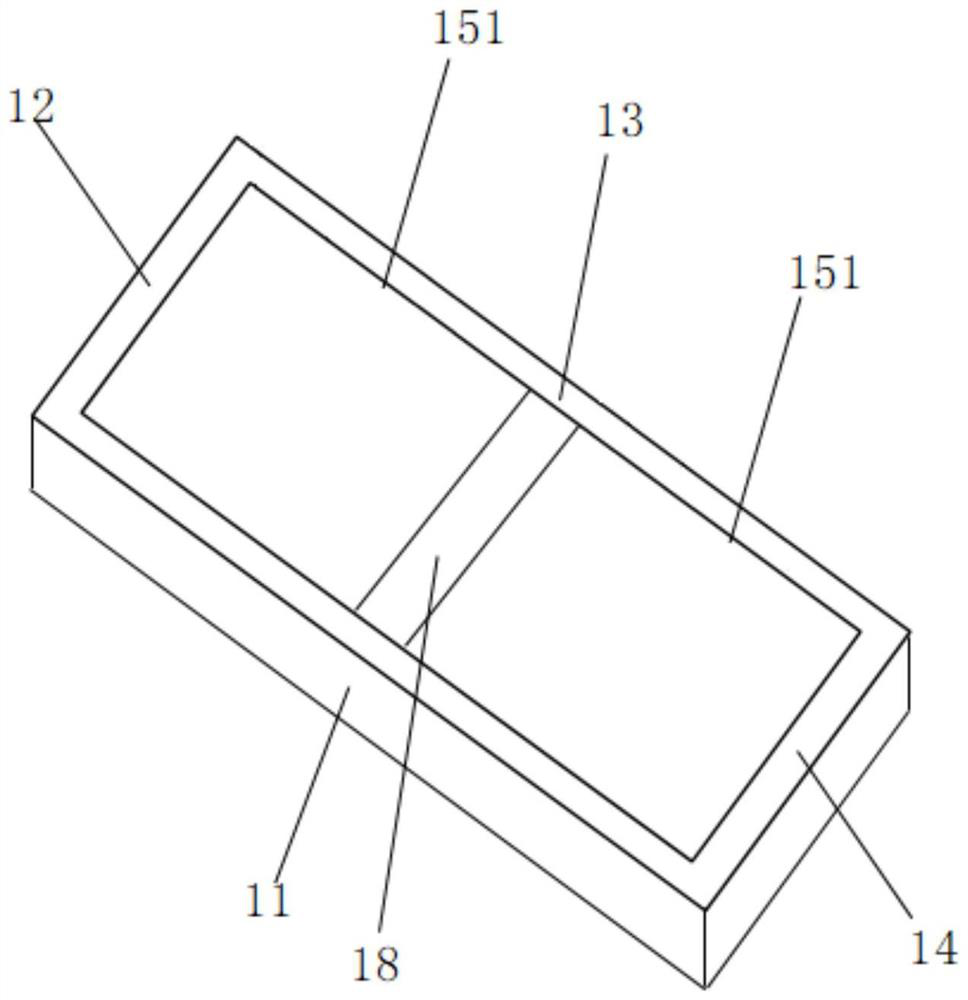

[0045] Such as image 3 , this embodiment discloses another LED bracket, which is manufactured by using the LED bracket manufacturing method described in Embodiment 1, and includes a metal layer electrode and a bracket body, and the bracket body includes two opposite first side plates 11, 13 and Two opposite second side plates 12, 14, two opposite first side plates 11, 13 are connected with two opposite second side plates 12, 14 to form an accommodating cavity, and a baffle plate 18 is arranged in the accommodating cavity The two ends of the baffle plate 18 are respectively connected with the two opposite first side plates 11, 13 to form two small accommodating cavities 151, and the baffle plate 18 is made of opaque material.

[0046] For other details of this embodiment, please refer to the foregoing embodiment, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com