Workshop warehouse automatic door

A technology for automatic doors and warehouses, applied to windows/doors, door/window accessories, window/door frames, etc., which can solve problems affecting the entry and exit of goods handling vehicles, laborious door opening methods, and labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

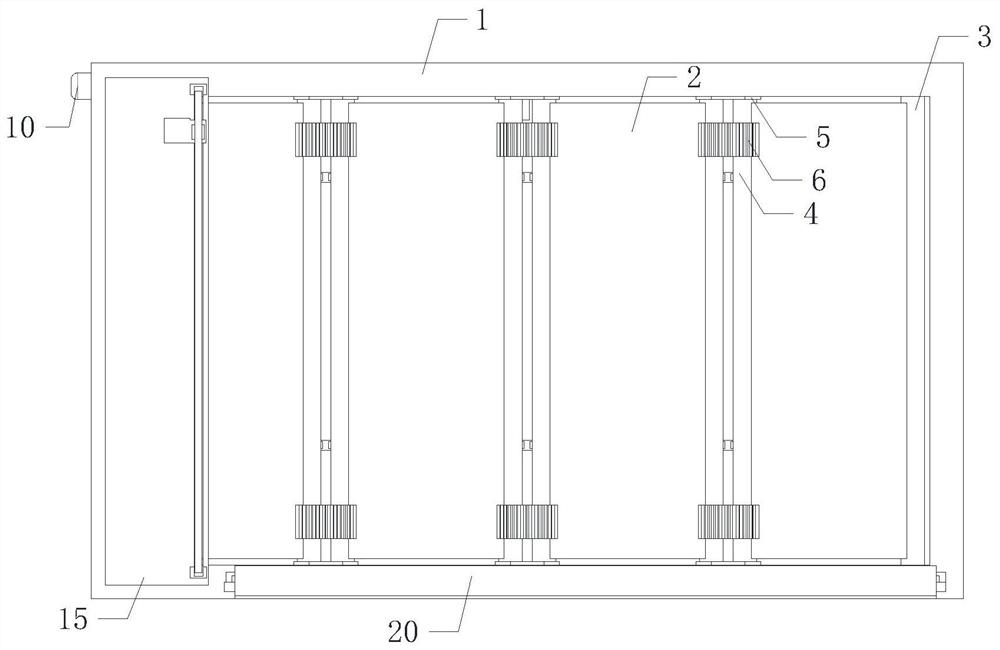

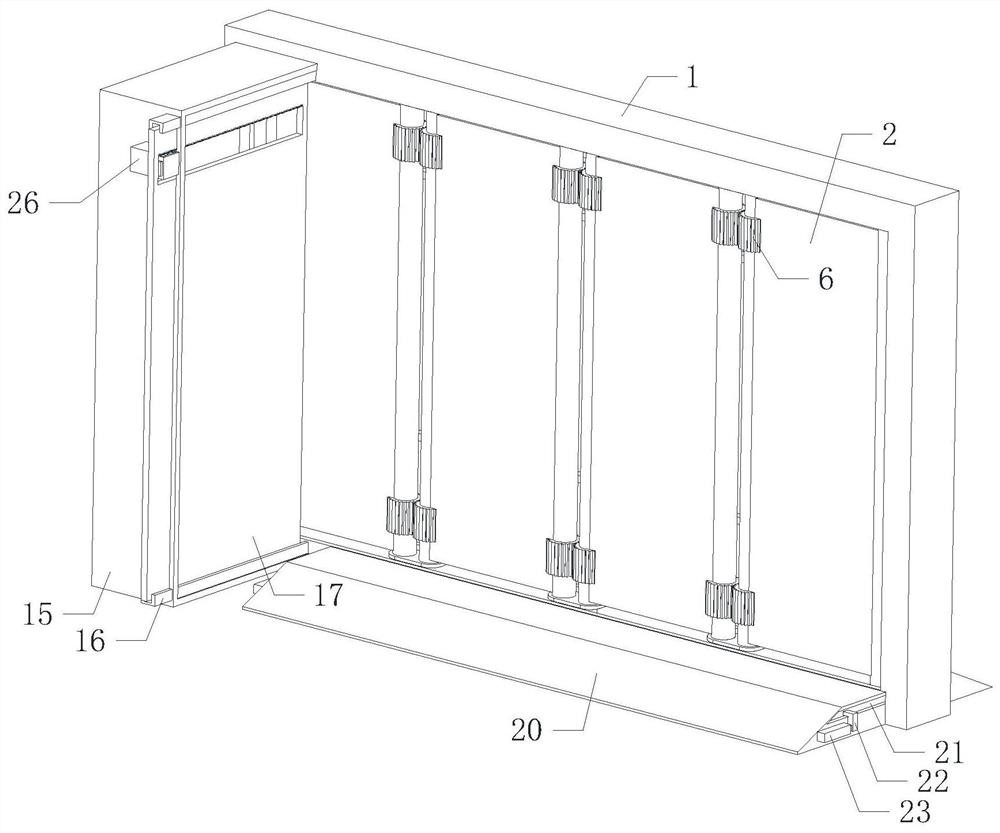

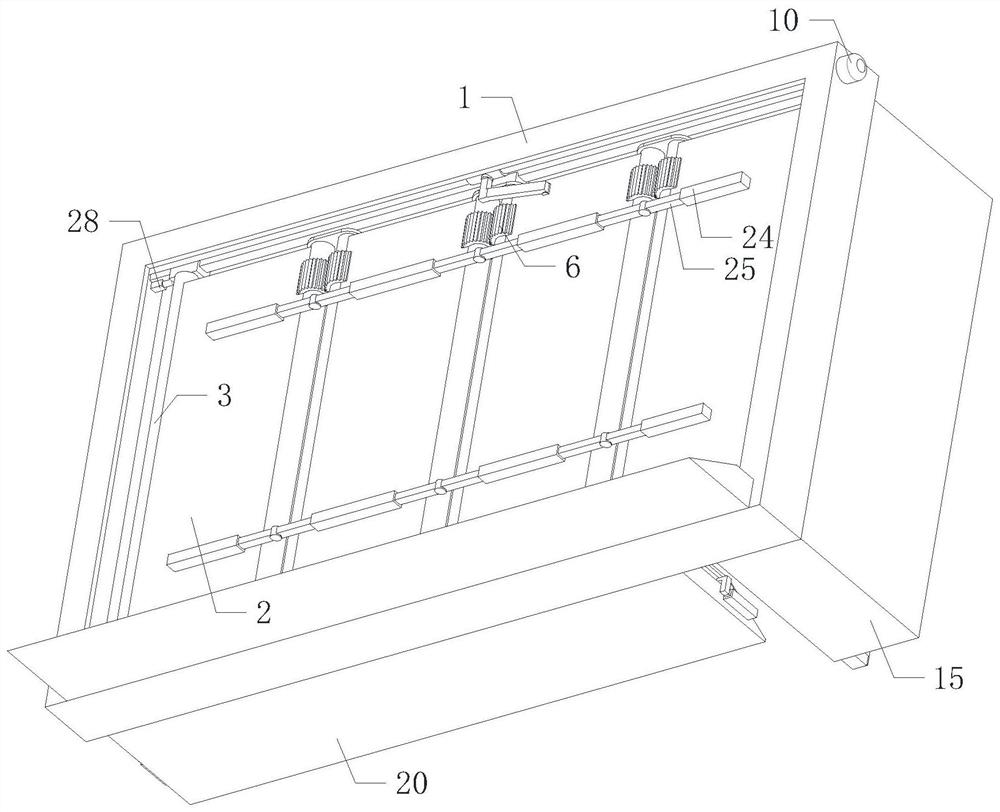

[0022] Such as Figure 1 to Figure 7 As shown, a kind of workshop warehouse automatic door of the present invention, when it is working, equipment is installed on the outside workshop warehouse door position, opens first motor 10, and first motor 10 drives lead screw 9 to rotate, and lead screw 9 and screw The sleeve 11 is screw-mounted and connected, and the lead screw 9 pulls the screw sleeve 11 to move to the left. Since the left side of the push frame 14 is tilted forward, the push frame 14 is respectively connected to the screw sleeve 11 and the second group of door bodies 2, and moves to the left. The threaded sleeve 11 in the best state generates a push force to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com