Automatic collecting vehicle for clock milk crystal salt in salt pan

A technology of stalactites and collecting vehicles, which is applied to motor vehicles, tracked vehicles, transportation and packaging, etc., can solve problems such as fatigue and staff injuries, and achieve the effect of improving work efficiency and avoiding breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

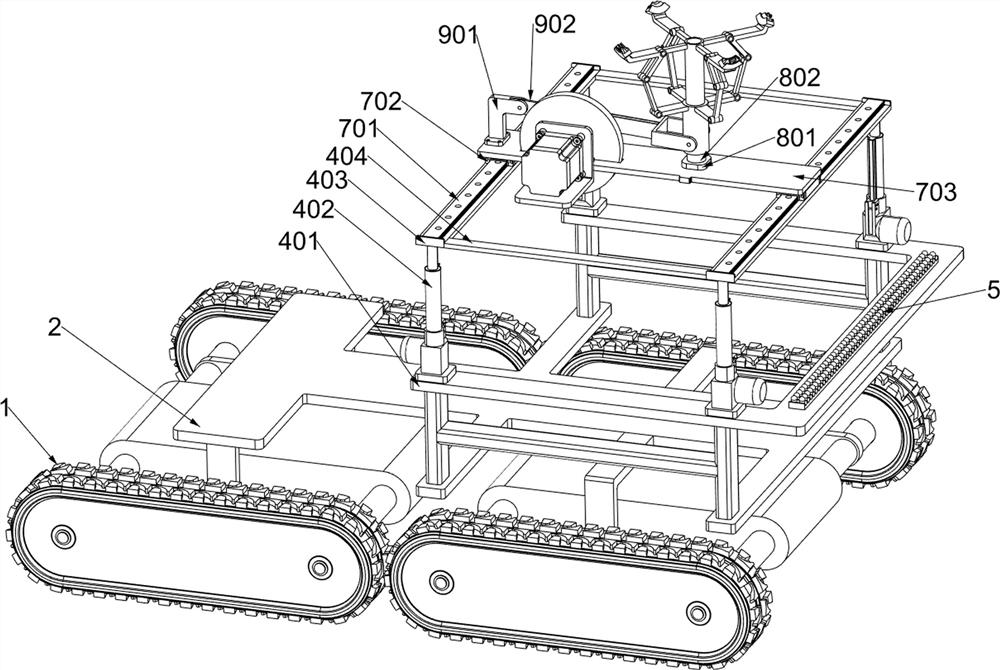

[0031] An automatic collection vehicle for stalactite salt used in salt fields, such as Figure 1-5As shown, it includes a moving mechanism 1, a frame 2, a lifting mechanism 4, an imaging probe 5, a translation mechanism 7, a grasping and cutting mechanism 8, and a transmission mechanism 9; the moving mechanism 1 is connected with a frame 2; the right part of the frame 2 A lifting mechanism 4 is connected; the upper part of the lifting mechanism 4 is connected with a translation mechanism 7; the upper part of the translation mechanism 7 is connected with a grasping and cutting mechanism 8; the upper part of the translation mechanism 7 is connected with a transmission mechanism 9, and the right part of the transmission mechanism 9 is connected with the grasping and cutting mechanism 8 connections; several imaging probes 5 are fixedly connected to the right part of the lifting mechanism 4 .

[0032] When in use, move the automatic stalactite salt collection vehicle for Yantian t...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 1-6 As shown, the lifting mechanism 4 includes a C-shaped mounting plate 401, an electric push rod 402, a first mounting plate 403 and a first connecting plate 404; the right part of the frame 2 is bolted to a C-shaped mounting plate 401; the C-shaped mounting plate 401 Four electric push rods 402 are connected by bolts on the upper surface, and the four electric push rods 402 are symmetrical; Mounting plate 403 ; two first mounting plates 403 are fixedly connected with a first connecting plate 404 at the opposite front and rear opposite sides, and the imaging probe 5 is connected to the right part of the upper surface of the C-shaped mounting plate 401 .

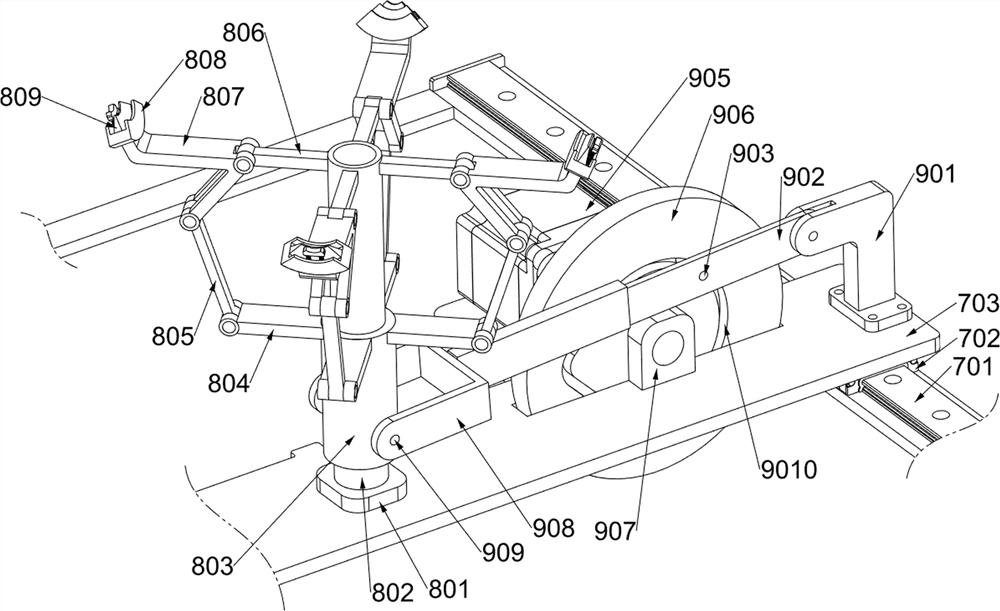

[0035] The translation mechanism 7 includes a fourth slide rail 701, a second slide block 702 and a third mounting plate 703; each of the two first mounting plates 403 is equipped with a fourth slide rail 701; each of the two fourth slide rails 701 A second sliding block 70...

Embodiment 3

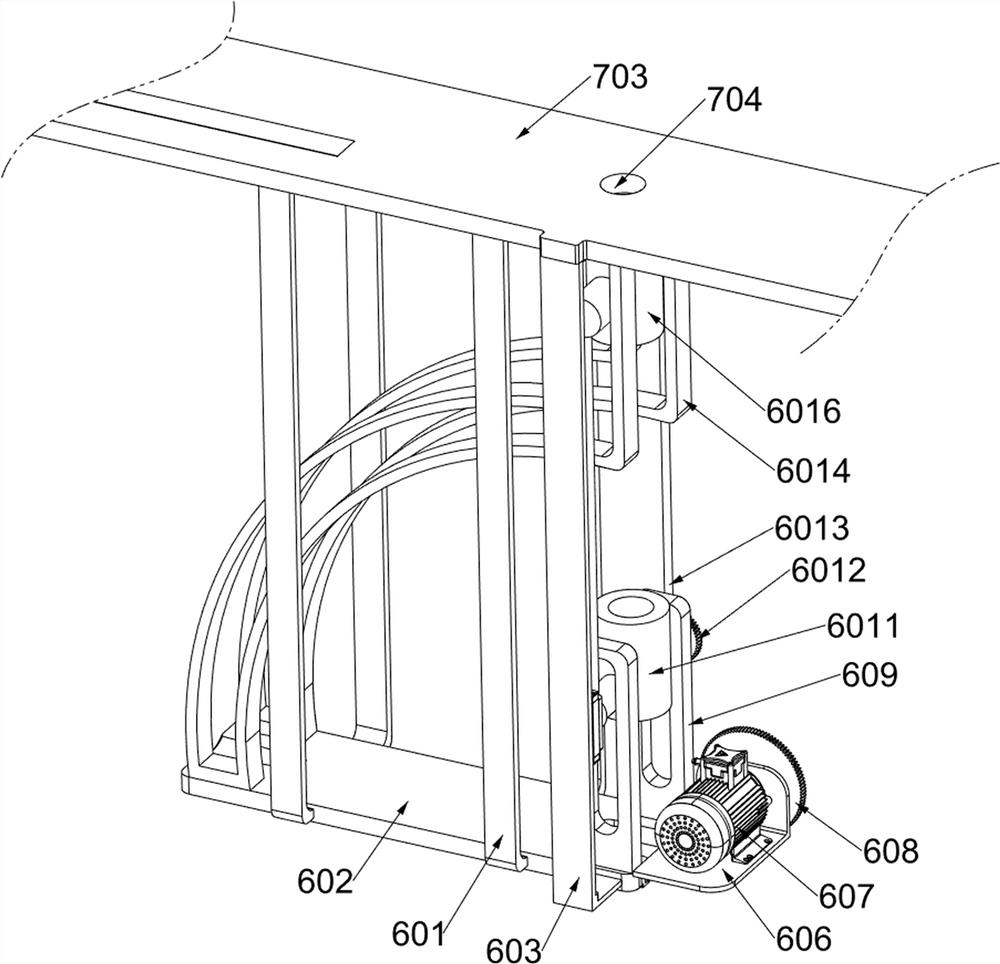

[0042] On the basis of Example 2, such as figure 1 and Figure 6-10 As shown, a transfer assembly 6 is also included; the lower part of the third mounting plate 703 is connected to the transfer assembly 6; the transfer assembly 6 includes a second connecting plate 601, a second mounting plate 602, a third connecting plate 603, and a first slide rail 604 , the first slider 605, the first mount 606, the first motor 607, the first gear 608, the second slide rail 609, the first slide rod 6010, the first transfer cylinder 6011, the second gear 6012, the first connecting rod 6013, the third sliding rail 6014, the second sliding rod 6015 and the second transfer cylinder 6016; the lower surface of the third mounting plate 703 is connected with four second connecting plates 601; the four second connecting plates 601 are symmetrical in pairs; The bending part of the second connecting plate 601 is fixedly connected with a second mounting plate 602; Welding; the right part of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com