A virtual pre-splicing tool for steel structure

A steel structure, pre-assembled technology, applied in the direction of welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of rough weld width adjustment, internal stress changes, angle differences, etc., and achieve the effect of avoiding welding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

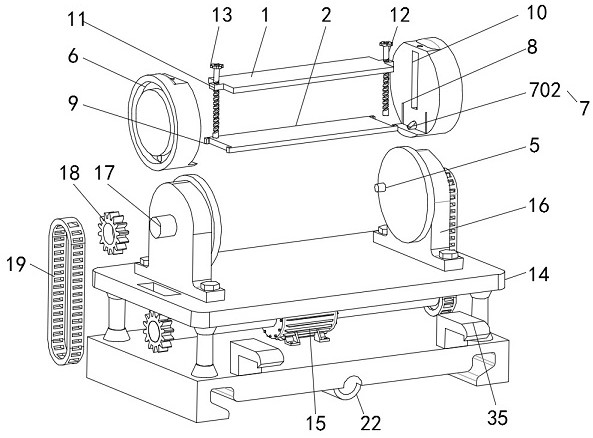

[0039] see Figure 1-3 , a steel structure virtual pre-splicing tool, including a pressure plate 1 and a firing plate 2 that can approach each other, and a pressure bearing plate 3 and a drive plate 4 that can be locked with each other;

[0040] One side of the drive plate 4 is provided with a drive column 5 , and one side of the pressure bearing plate 3 is provided with a drive ring groove 6 tangent to the drive column 5 , and the drive column 5 surrounds the drive ring groove 6. Do a circular motion, a firing member 7 is arranged in the pressure bearing plate 3, and the firing member 7 can enter the driving ring groove 6 by applying force to the firing member 7 through the firing plate 2 so that the firing member 7 can interact with the driving ring groove 6. The column 5 is in contact to realize the linkage between the drive plate 4 and the pressure plate 3 .

[0041] Therefore, before the drive plate 4 rotates, the pressure plate 3 rotates at will, so that the opposite surf...

Embodiment 2

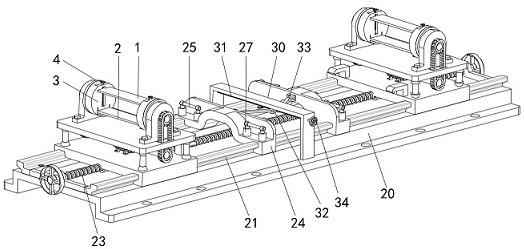

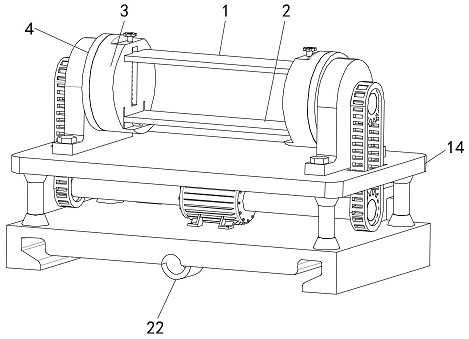

[0056] see figure 1 and image 3 , and also includes a translation assembly, the translation assembly includes a base 20 and a slide rail 21, the slide rails 21 are fixedly installed on both sides of the upper surface of the base 20, and the slide rail 21 and the mounting seat 14 is slidingly connected, the lower surface of the mounting seat 14 is provided with a threaded seat 22, the threaded seat 22 penetrates and is threadedly connected with a translation screw 23, and the translation screw 23 is rotatably connected to the base 20;

[0057] Both ends of the mounting seat 14 are fixedly installed with hooks 35, and the translation assembly drives the mounting seat 14 to translate so that the hooks 35 are engaged with the self-locking assembly;

[0058] The self-locking assembly includes a self-locking seat 24, the self-locking seat 24 is slidably mounted on the slide rail 21, and both ends of the self-locking seat 24 are provided with clamping rods 25, and the clamping rods...

Embodiment 3

[0064] see figure 1 and image 3 , a gantry frame 30 is fixedly installed in the middle of the upper surface of the base 20, the gantry frame 30 is penetrated and is rotatably connected with a distance adjustment screw 31, and the distance adjustment screw 31 is penetrated and screwed with a distance adjustment block 32. One side of the distance adjustment block 32 is rotatably connected with a connecting plate 33, and one end of the connecting plate 33 is rotatably connected to one side of the self-locking seat 24;

[0065] A distance adjustment knob 34 is fixedly connected to one end of the distance adjustment screw 31 .

[0066] By rotating the distance adjustment knob 34, the distance adjustment knob 34 drives the distance adjustment screw 31 to rotate, so that the distance adjustment block 32 moves along the lower surface of the gantry frame 30, and then drives the self-locking seat 24 through the connecting plate 33 to move along the slide rail 21 is moved, so as to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com