Operating frame erecting tool

A technology for operating frames and tools, which is applied to the accessories of scaffolding, building structure support, building structure support, etc. It can solve the problems of safety accidents, instability and falling of rods, etc., so as to prevent safety accidents, reduce labor intensity, and achieve good connection effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

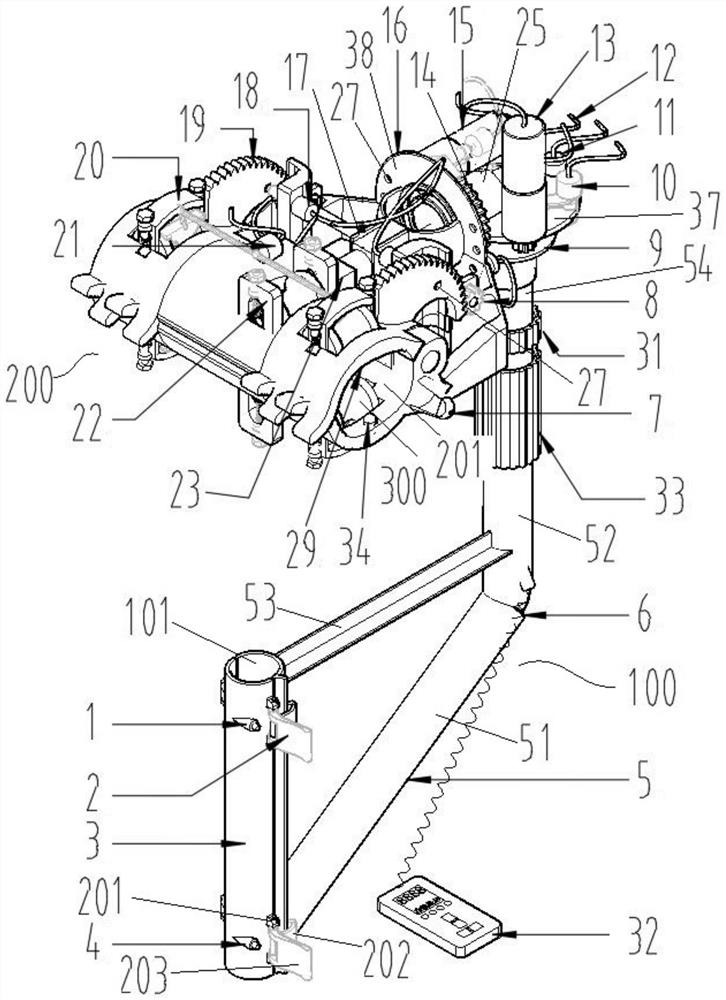

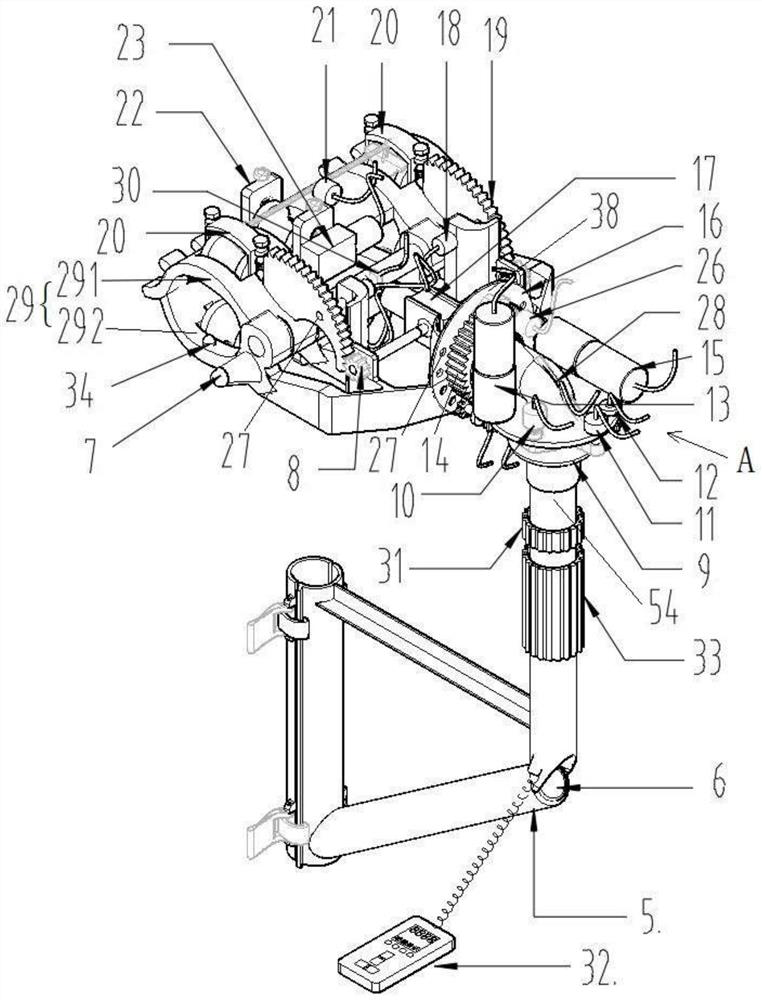

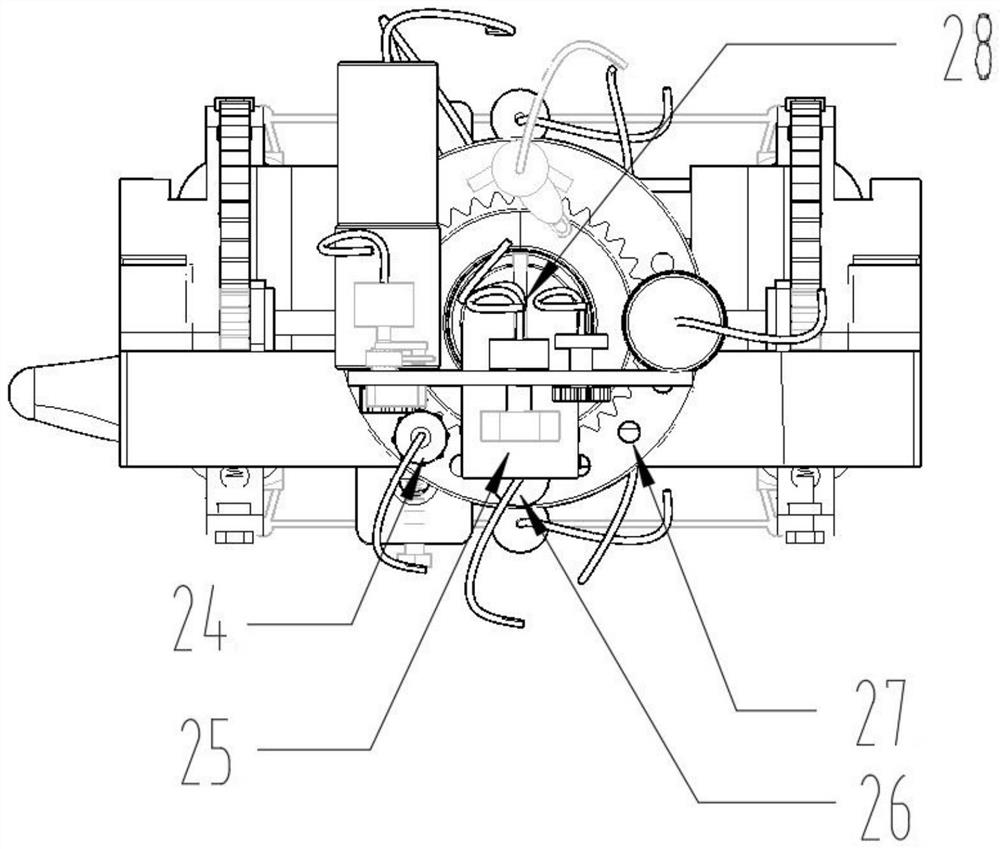

[0023] Such as Figure 1~3 As shown, an operating frame erecting tool provided in this embodiment includes a frame body 100 , a clamp assembly 200 , a first rotary assembly 9 , a second rotary mechanism 16 , a wire-controlled operation switch 32 , a control display panel 35 and a control board 36 .

[0024] Such as figure 1 As shown, the frame body 100 includes a first contact sensor switch 1 , a support 3 , a locking switch 2 , a second contact sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com