Bidirectional laser welding auxiliary jig

A laser welding, bidirectional technology, used in laser welding equipment, welding equipment, manufacturing tools and other directions, can solve the problem of low efficiency of cell welding fixture replacement, to improve the efficiency beat, convenient and simple operation, and change the efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

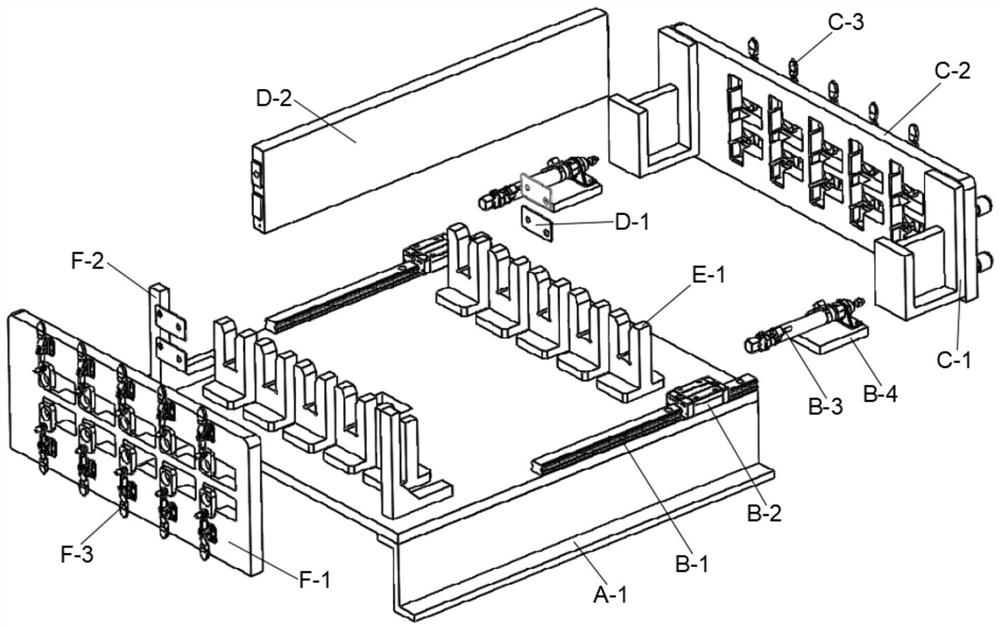

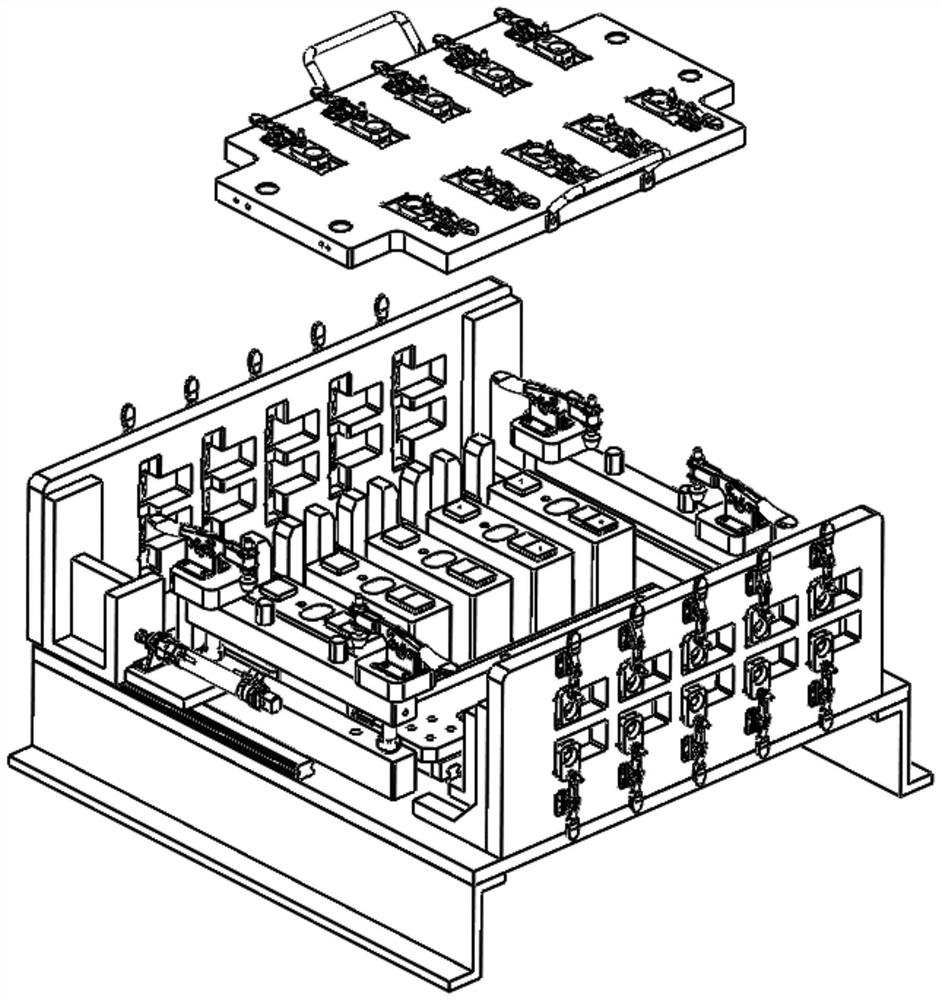

[0021] Embodiment one, with reference to the specification attached figure 1 , a bidirectional laser welding auxiliary jig, including a jig main body and a welding cell D, the jig main body includes a welding mechanism, the welding mechanism is used for horizontally welding the welding cell D, and the welding mechanism includes a bracket assembly A, a horizontal tensioning assembly B. The movable end C of the horizontal welding jig, the cell positioning slot E and the fixed end F, the bracket assembly A includes the platform frame A-1, the horizontal tensioning assembly B includes the first slide rail B-1 and the sliding installation on the second The first slider B-2 on a slide rail B-1, the first slider B-2 is fixed with a pressing actuator fixing block B-4, and the top of the pressing actuator fixing block B-4 is fixedly installed with The horizontal clamping actuator B-3, the movable end C of the horizontal welding fixture includes the clamping plate C-2, the fixed end F i...

Embodiment 2

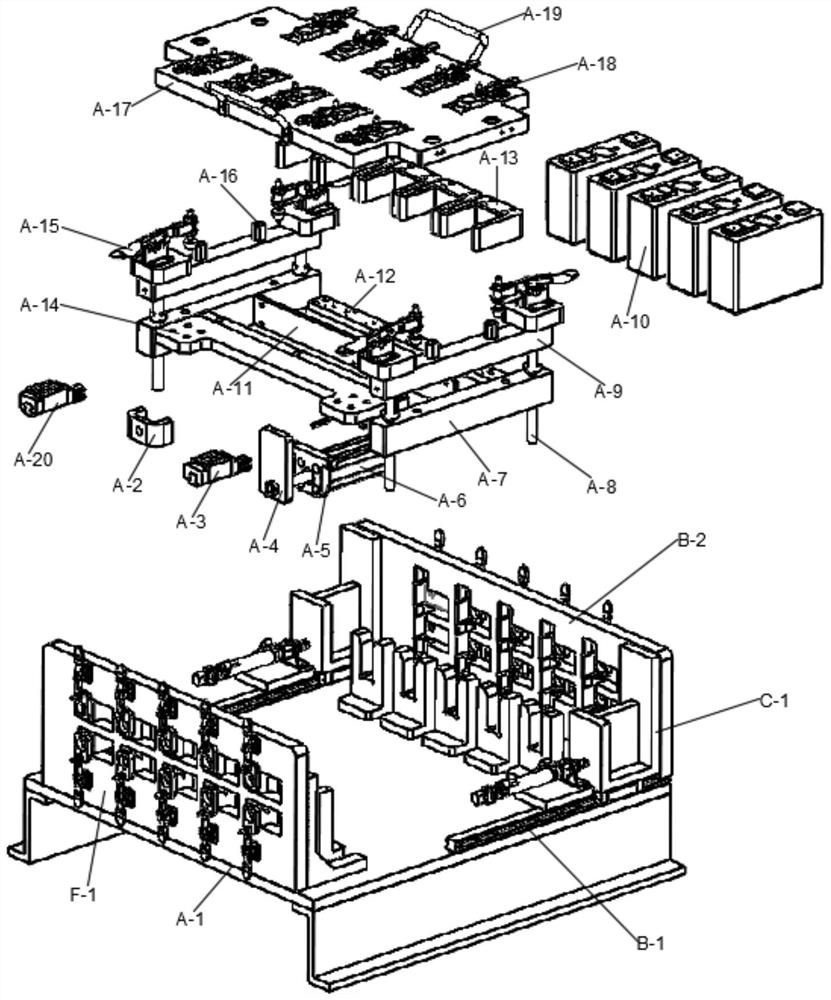

[0022] Embodiment two, with reference to the appended figure 2, a bidirectional laser welding auxiliary jig, including a jig main body and a welding cell D, the jig main body includes a welding mechanism, including a welding mechanism for vertically welding the welding cell D, the welding mechanism includes a bracket assembly A, a horizontal tensioning Component B, the movable end C of the horizontal welding fixture, the cell positioning slot E and the fixed end F, the bracket component A includes the platform frame A-1, the horizontal tensioning component B includes the first slide rail B-1 and is slidably installed on The first slider B-2 on the first slide rail B-1, the first slider B-2 is fixed with the pressing actuator fixing block B-4, and the top of the pressing actuator fixing block B-4 is fixed and installed There is a horizontal clamping actuator B-3, the movable end C of the horizontal welding jig includes a clamping plate C-2, and the fixed end F includes a cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com