Oil guide cotton with preset assembly structure and processing technology of oil guide cotton

A technology of processing technology and assembly structure, applied in the field of electronic cigarettes, can solve the problems of no preset assembly measures, affecting the use of users, and difficult to connect the heating wire, so as to reduce the leakage of e-liquid, improve the oil storage rate, and improve the strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

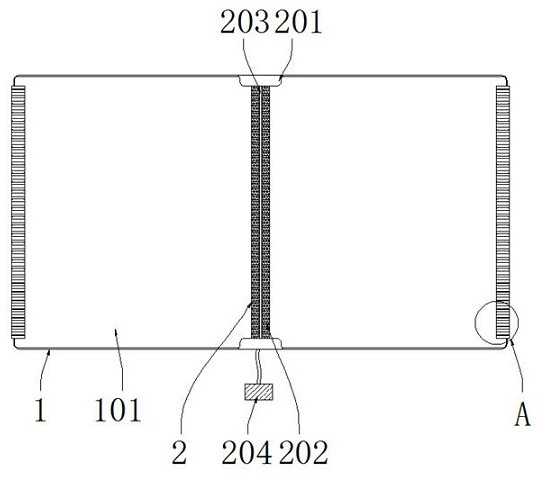

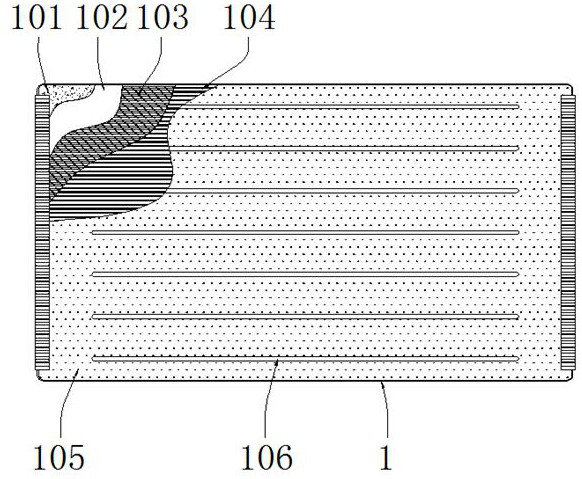

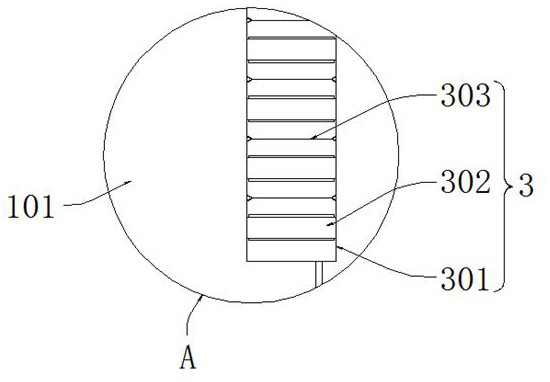

[0027] see Figure 1-3 , the present invention provides a technical solution: an oil-conducting cotton with a preset assembly structure and its processing technology, including an oil-conducting cotton 1 and a pre-assembled component 3, a tightening component 2 is installed in the middle of the oil-conducting cotton 1, and a pre-assembled The accessory component 3 is installed on both sides of the oil guide cotton 1, and the tightening component 2 includes the closing cotton 201, the tightening net 202, the marking line 203 and the hook fleece 204, and the closing cotton 201 is provided with a tightening net 202, and the tightening net 202 The surface is provided with marking lines 203, and the back of the tightening net 202 is provided with hook fleece 204, the pre-assembled component 3 includes a storage frame 301, a bump 302 and a crease 303, and the surface of the storage frame 301 is provided with a bump 302, the bump A crease 303 is provided on one side of the 302;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com