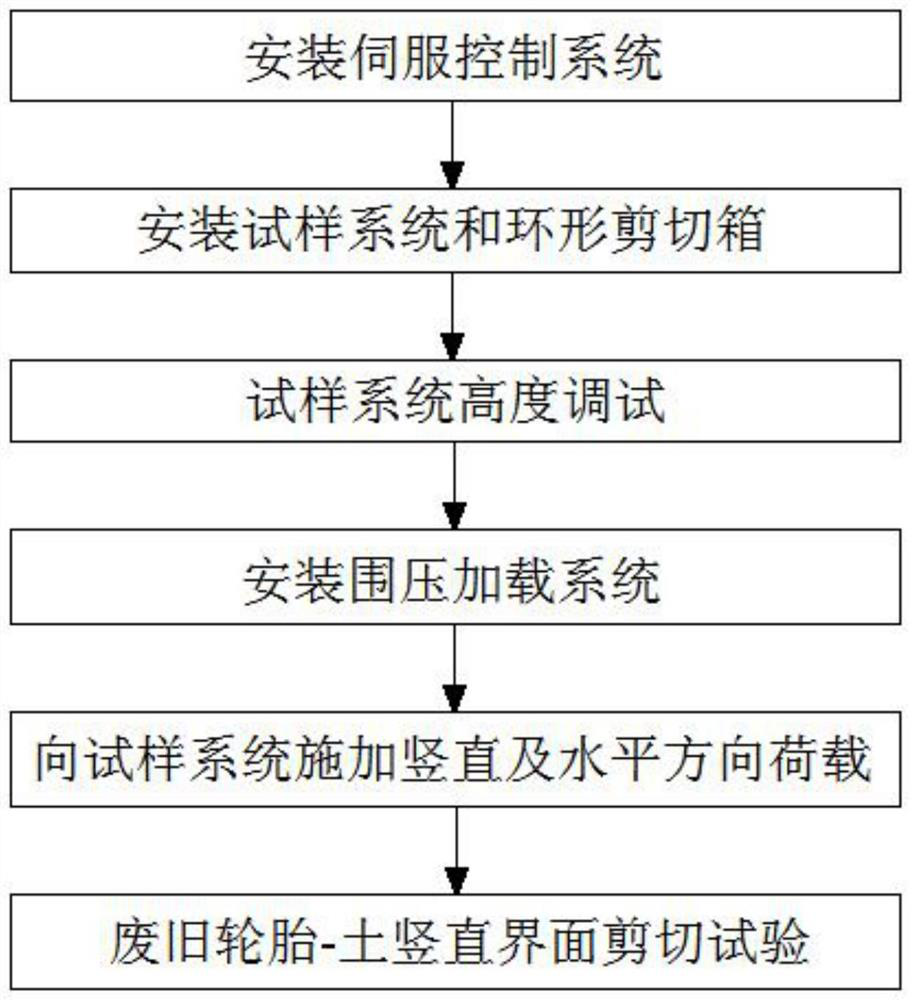

Waste tire-soil vertical interface shear characteristic testing method

A waste tire and characteristic testing technology, which is applied in the field of reinforced soil engineering, can solve the problems that the interface mechanical property test of different specifications and sizes cannot be applied, cannot be realized, and the vertical interface shear test cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

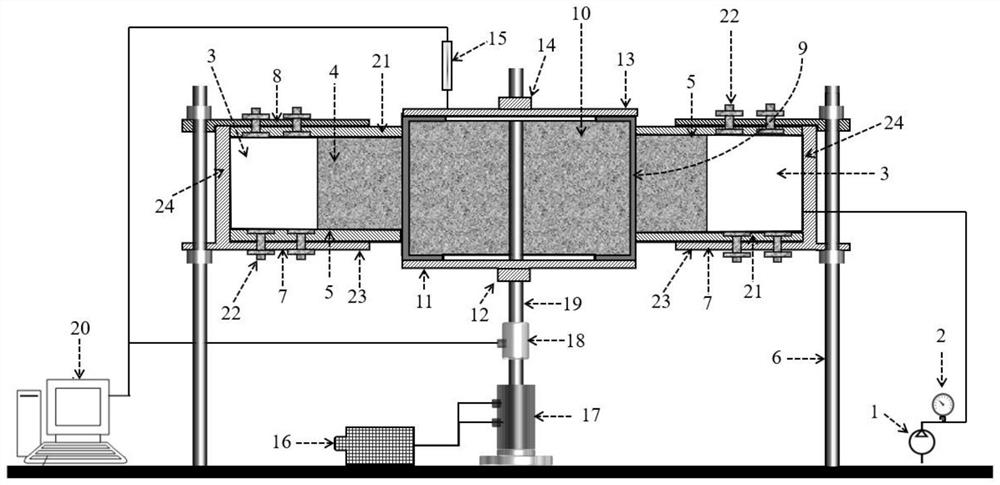

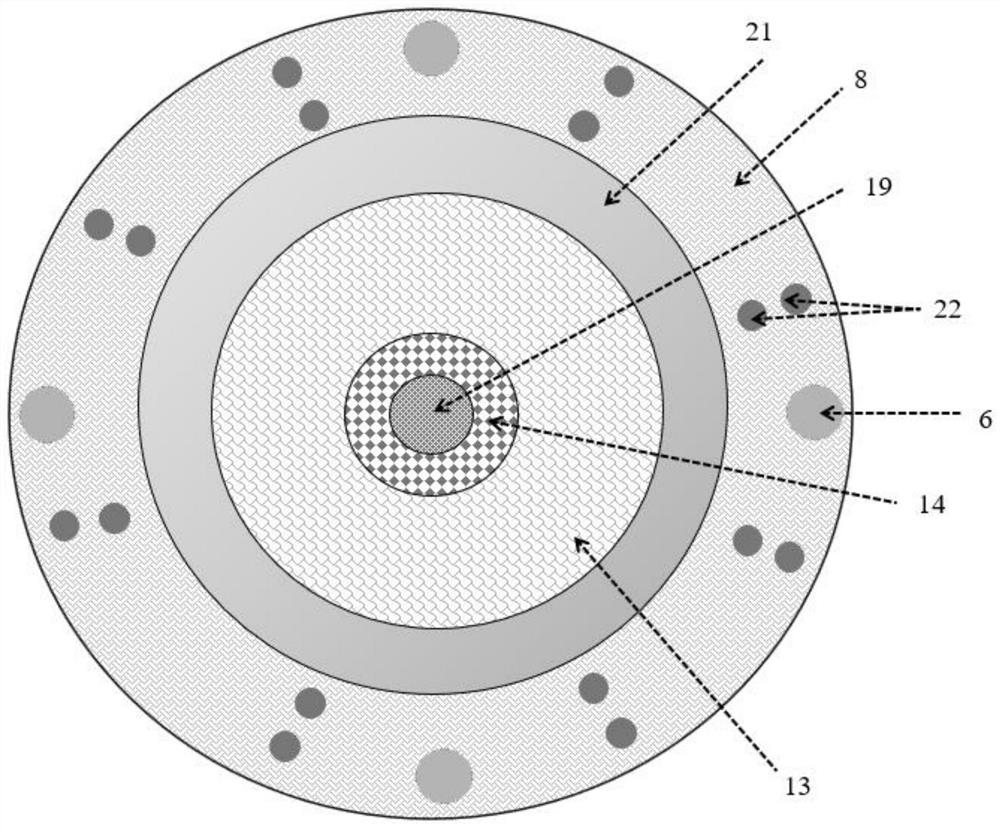

Method used

Image

Examples

Embodiment

[0065] According to the above process, first simulate the buried depth of 15 meters, apply a vertical load of 300kPa in step S5, the confining pressure in the first test is 45.1kPa, the reading of the stress sensor is 28.4kPa, and the confining pressure in the second test is 60.5 kPa, the reading of the stress sensor is 34.1kPa, and the following binary linear equations are established:

[0066]

[0067] Solutions have to: c=12kPa. Therefore, the shear mechanical parameters of the waste tire-soil vertical interface at a buried depth of 15m are: the cohesion force is 12kPa, and the internal friction angle is 20°.

[0068] Then in step S5, the vertical load is changed to 100kPa, that is, the simulated buried depth is 5 meters, the above process is repeated and the shear mechanics parameters corresponding to the waste tire-soil vertical interface are calculated as follows: the cohesion is 11kPa, and the internal friction angle is 15 °.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com