Butt-joint installation method for rectangular steel stand columns through first beam and second column lifting in narrow space

A narrow space, docking installation technology, applied in the direction of columns, piers, pillars, etc., can solve problems such as slowing down the progress of the project, and achieve the effect of speeding up the progress of the project and reducing the amplitude of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

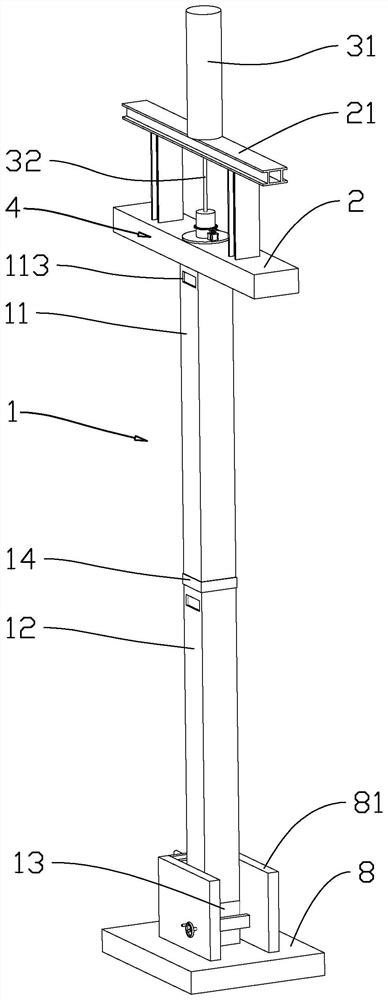

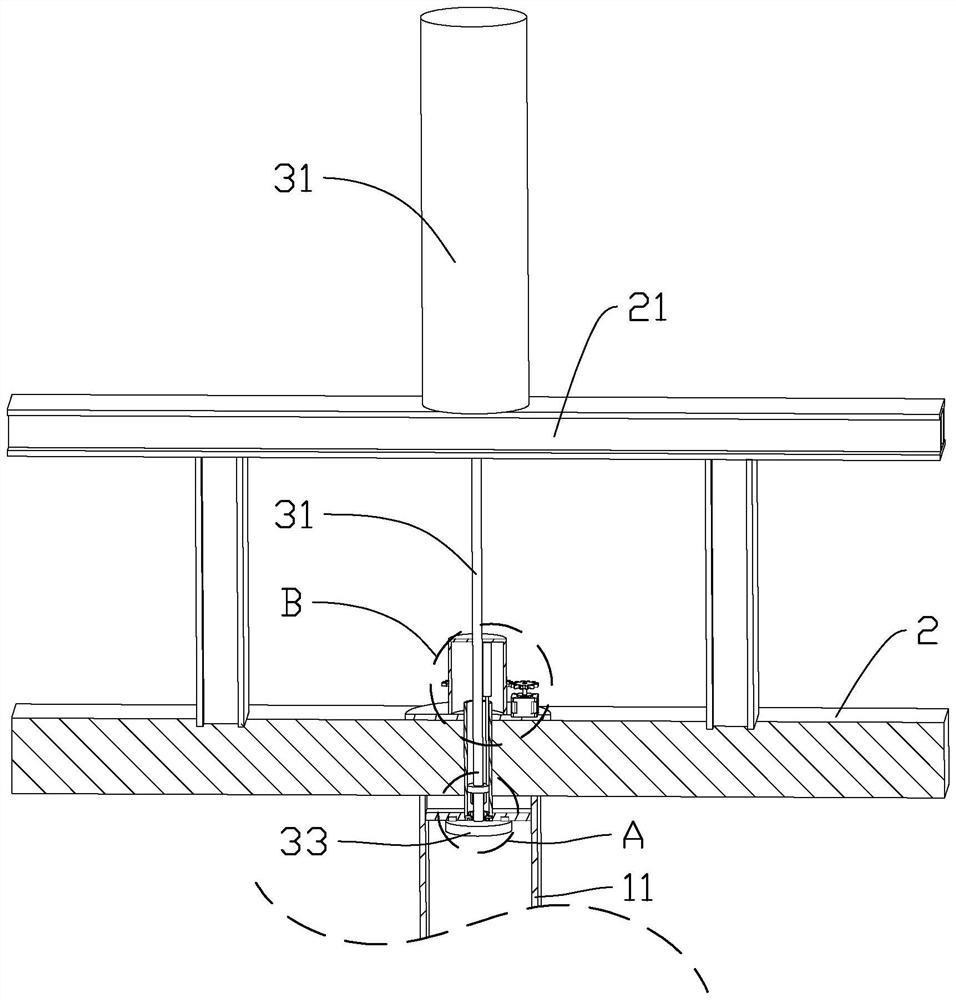

[0040] The embodiment of the present application discloses a method for butt joint installation of a rectangular steel column by first lifting the beam and then the column in a narrow space. refer to figure 1 , figure 2 , In a narrow space, the installation method of butt joint installation of rectangular steel columns includes the following construction steps:

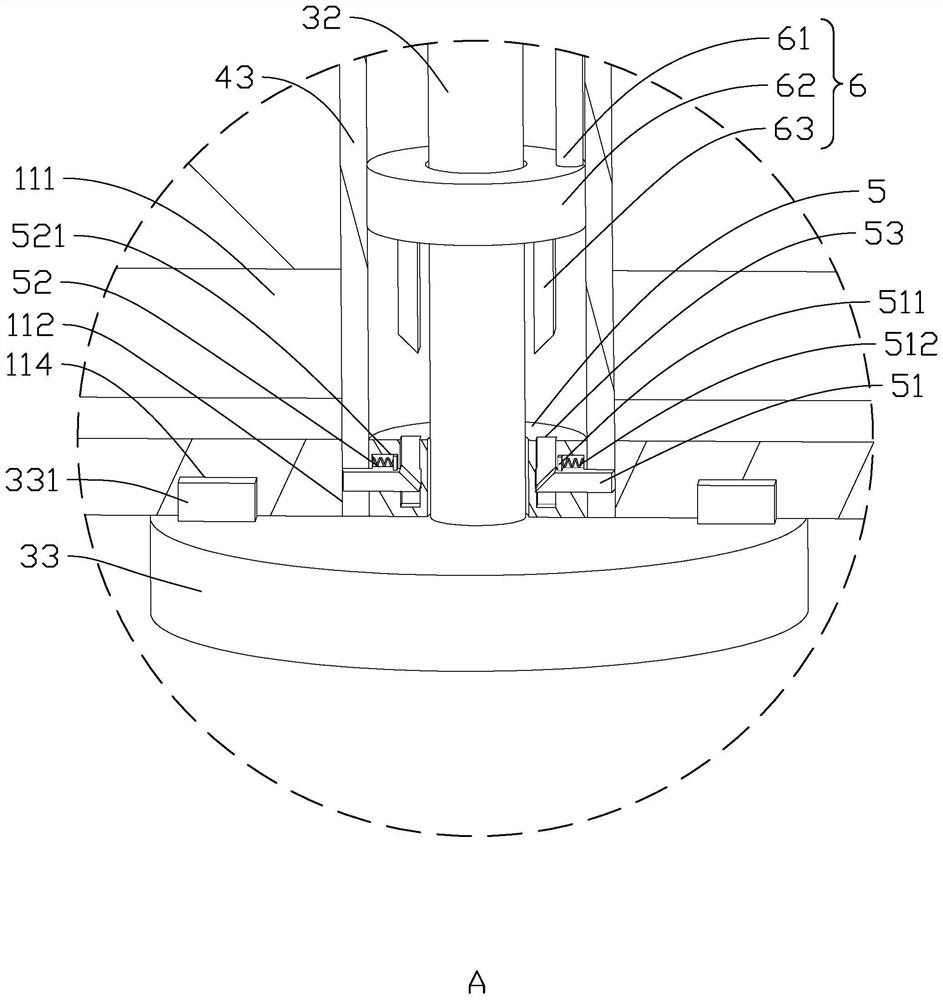

[0041] S1. Divide the steel column 1 into the first section column 11, the second section column 12 and the third section column 13, install the third section column 13 on the lower platform 8, and install the steel column at the end of the upper platform 2 A lifting bracket 21 is arranged on the beam, and a hydraulic lifter 3 and a control assembly 4 for adjusting the position of the first column 11 are installed on the lifting bracket 21. The upper platform 2 is provided with a communication hole 22, and the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com