Backward-pushing and forward-pulling schoolbag trolley

A technology of trolleys and schoolbags, applied in the field of school supplies, can solve problems such as insufficient functions and difficulty for children to find

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

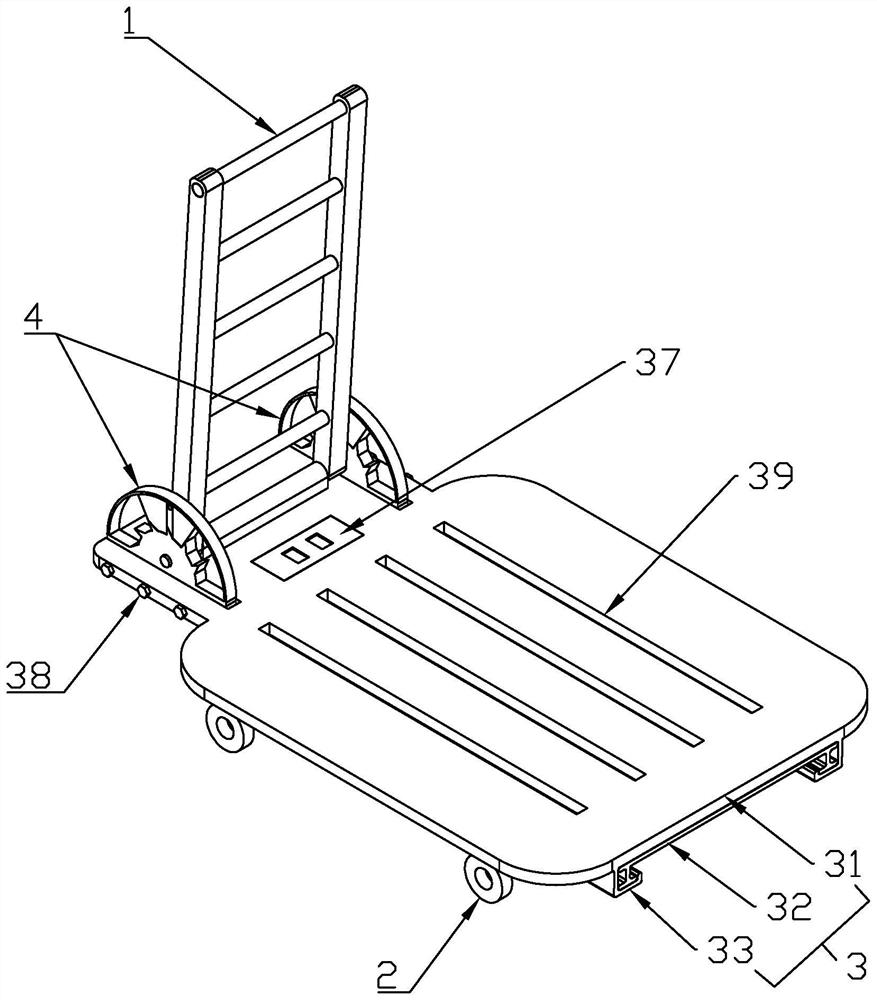

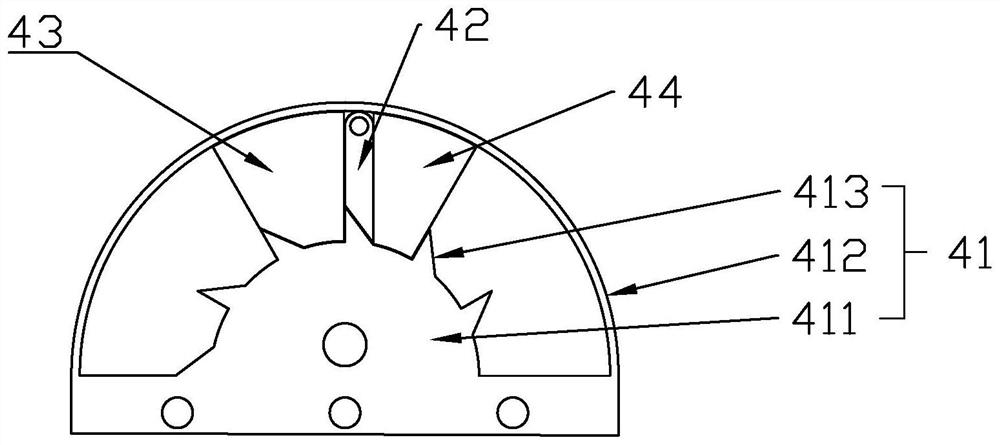

[0038] Embodiment one: if figure 1 , 3 , 4, 5 shows a schoolbag trolley 1 car with both reverse push and smooth pull, including a trolley 1 and a base plate assembly 3, and the base plate assembly 3 is linked with a pulley block 2 evenly distributed around the base plate assembly 3, so The base plate assembly 3 includes a load-bearing base plate 31 that can be used to place schoolbags. The pull rods 1 are distributed on the upper front end of the load-bearing base plate 31 and the ends of the two are hinged to each other. A push-pull direction adjustment mechanism is provided between the load-bearing base plate 31 and the pull rod 1. 4. The push-pull direction adjustment mechanism 4 includes an angle-adjusting half-circle 41 and a steering adjustment rod 42; the angle-adjusting half-circle 41 includes an angle-adjusting plate 411 with a regular semicircular shape, and a limit half around the periphery of the angle-adjusting plate 411. Ring body 412, an installation gap 414 is...

Embodiment 2

[0051] Embodiment two: if figure 2 , 3 , a kind of reverse pushing shown in 4,5 and the school bag trolley 1 car that pulls along concurrently, compared with embodiment one, tarpaulin 5, tie rope 6 are not provided, and all the other structures are the same as embodiment one.

[0052] The advantages of embodiment two are as follows:

[0053] (1) The angle adjustment range of the tie rod 1 can be expanded to 0° to 180°. When it is pulled forward (also called smooth pull), it can be pulled forward from 0° to 90°, and can be reversed between 90° and 180°. Push (at the same time observe the situation of the schoolbag, and further solve the problem of missing items), promote the diversification of the use status of the schoolbag trolley 1, increase the overall fun of the schoolbag trolley 1, meet the needs of students, and adjust the trolley 1 according to their own needs. state of need;

[0054] (2) Using the push-pull direction adjustment mechanism 4, the pull rod 1 can be fo...

Embodiment 3

[0057] Embodiment three: as Figures 1 to 4 The schoolbag trolley car with both reverse push and straight pull shown is the same as the first embodiment except the following structure. The upper end of the steering adjustment rod 42 is provided with a third abutment slope 422, and the anti-reversal limit block 44 is located on the side facing the steering adjustment rod 42 and is provided with a fourth abutment slope 441 and a plane abutment surface 442. The four abutting slopes 441 are in conflicting connection with the third abutting slope 422 , and the plane abutting surface 442 is in conflicting connection with the side surface of the steering adjustment rod 42 . The third abutment slope 422 is set on the upper end of the steering adjustment rod 42, so only the anti-reversal limit block 44 needs to be installed at this time, and there is no need to install the front pull drive block 43, reducing the number of parts of the push-pull direction adjustment mechanism 4, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com