Hanging type seeding machine

A technology of seeding machine and seeding mechanism, which is applied in the direction of hole sowing seeder, seeder parts, single seed seeder, etc., and can solve the problems of limited scale, semi-automatic on-demand machine hole distance, unstable hole grains, low efficiency, etc., and achieve granularity Uniform and consistent spacing, automatic precision and stable seeding operations, and the effect of ensuring air pressure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific embodiments.

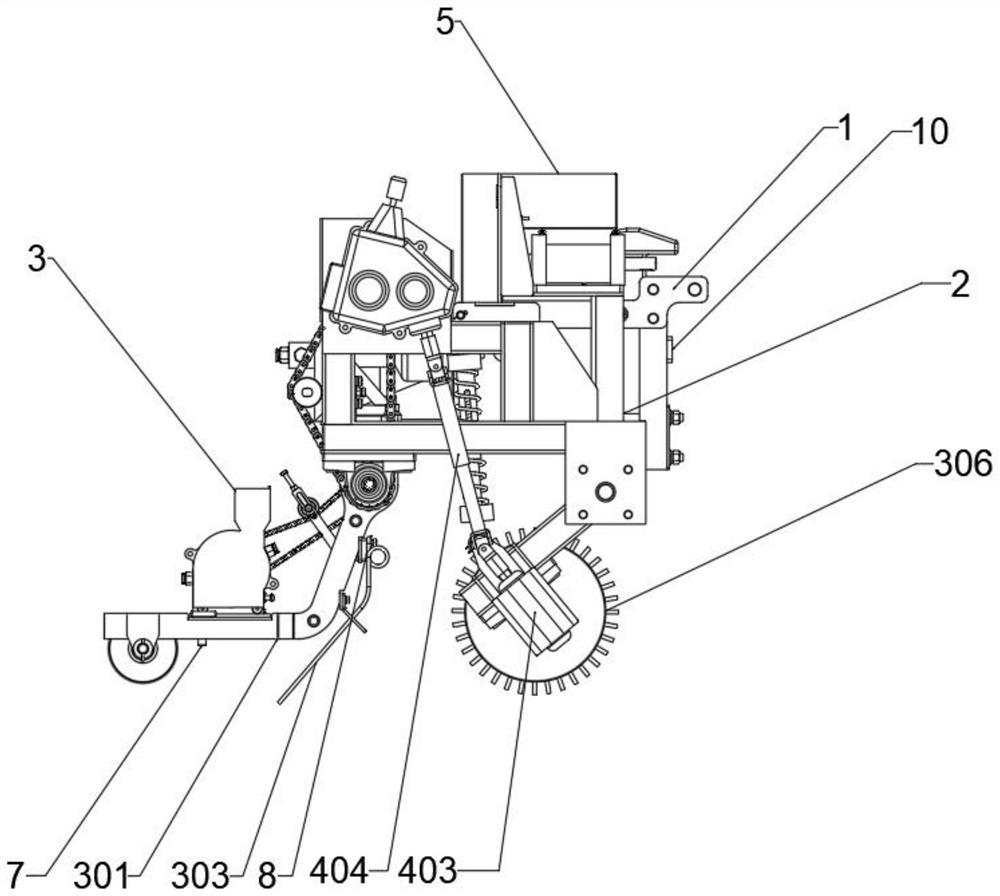

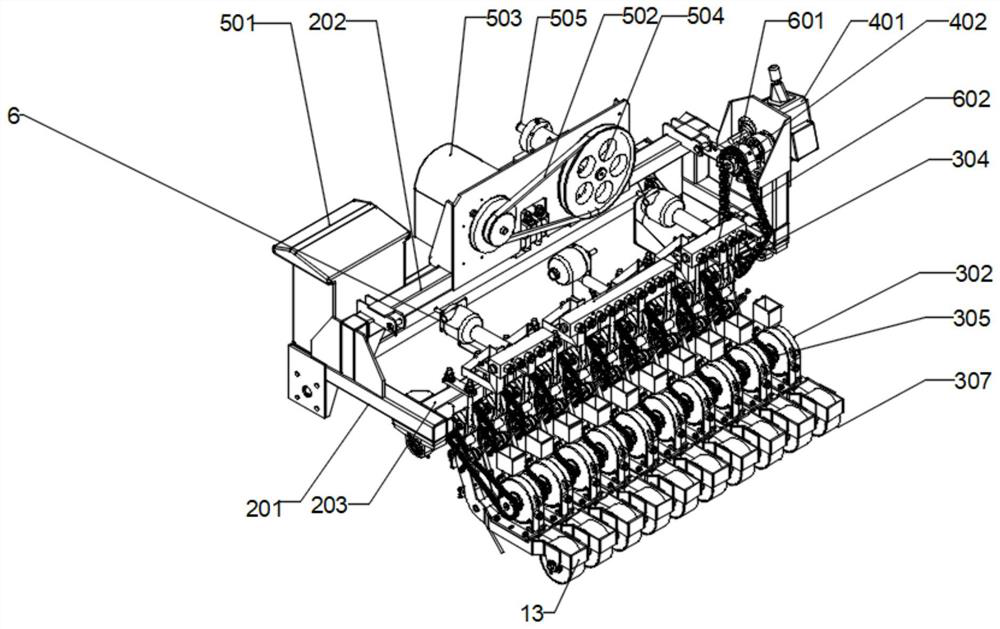

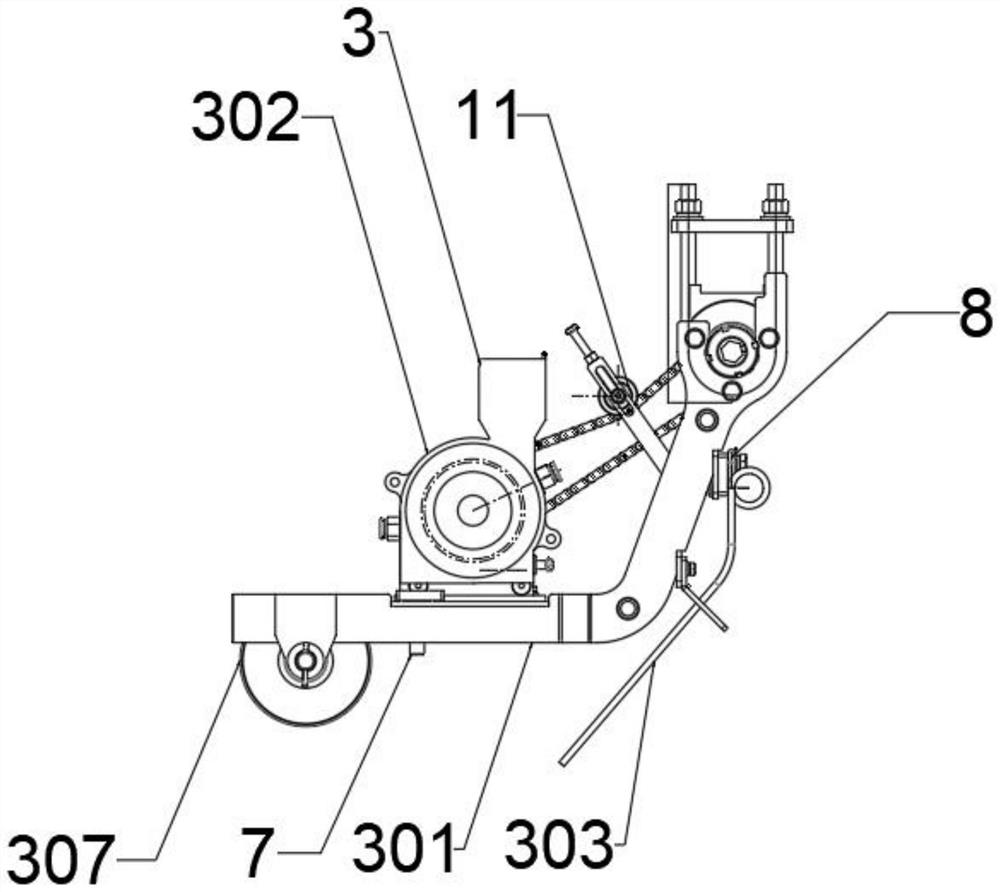

[0036] In the accompanying drawings of the present invention specification, 1 is a hitching mechanism; 2 is a frame, 201 is a side frame, 202 is a top frame, 203 is a rear frame, and 204 is a front frame; 3 is a seeding mechanism, 301 is a beam plate, 302 303 is the ditch opener, 304 is the driving sprocket of the seed meter, 305 is the driven sprocket of the seed meter, 306 is the front ground wheel, 307 is the rear pressing wheel; 4 is the power transmission mechanism, and 401 is the Reducer, 402 is the power output shaft sprocket of the reducer, 403 is the commutator, 404 is the joint; 5 is the fan power mechanism, 501 is the electric box, 502 is the V-belt, 503 is the generator, 504 is the pulley, 505 6 is the fan assembly, 601 is the negative air pressure confluence assembly, 602 is the positive air pressure confluence assembly; 7 is the seed drop tube; 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com