Soft package power lithium battery defect tab welding structure

A tab welding and lithium battery technology, which is applied to structural parts, welding equipment, laser welding equipment, etc., can solve the problems of low welding position accuracy, loose tabs, and inability to replace and connect tabs due to polymer battery core defects. The effect of improving the accuracy of welding position and preventing the tab from loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

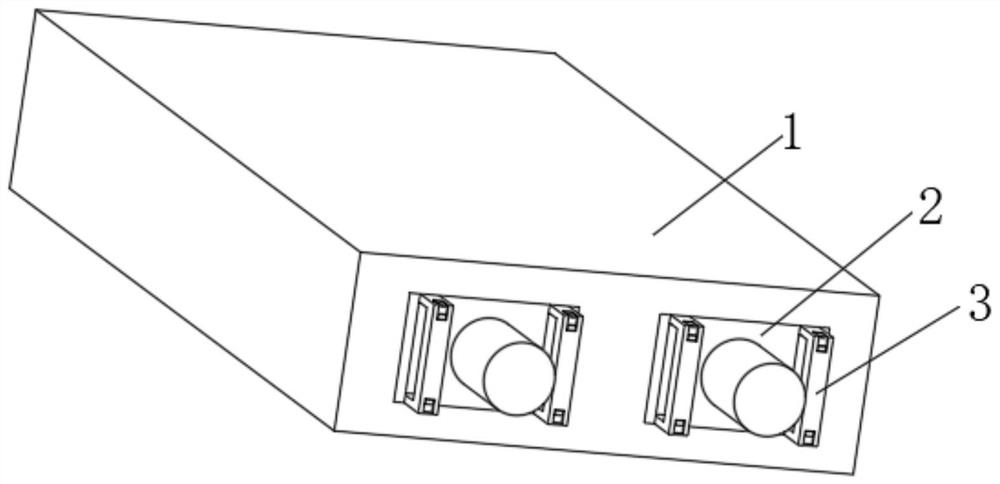

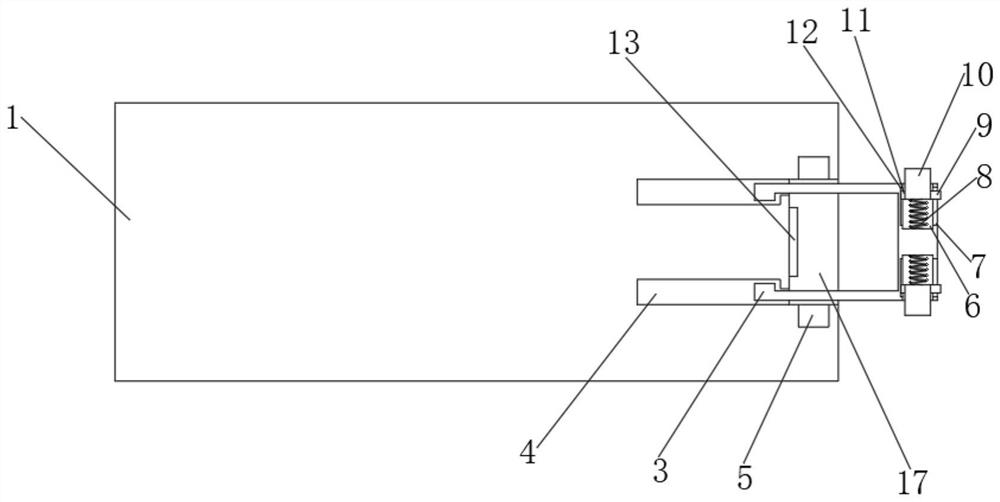

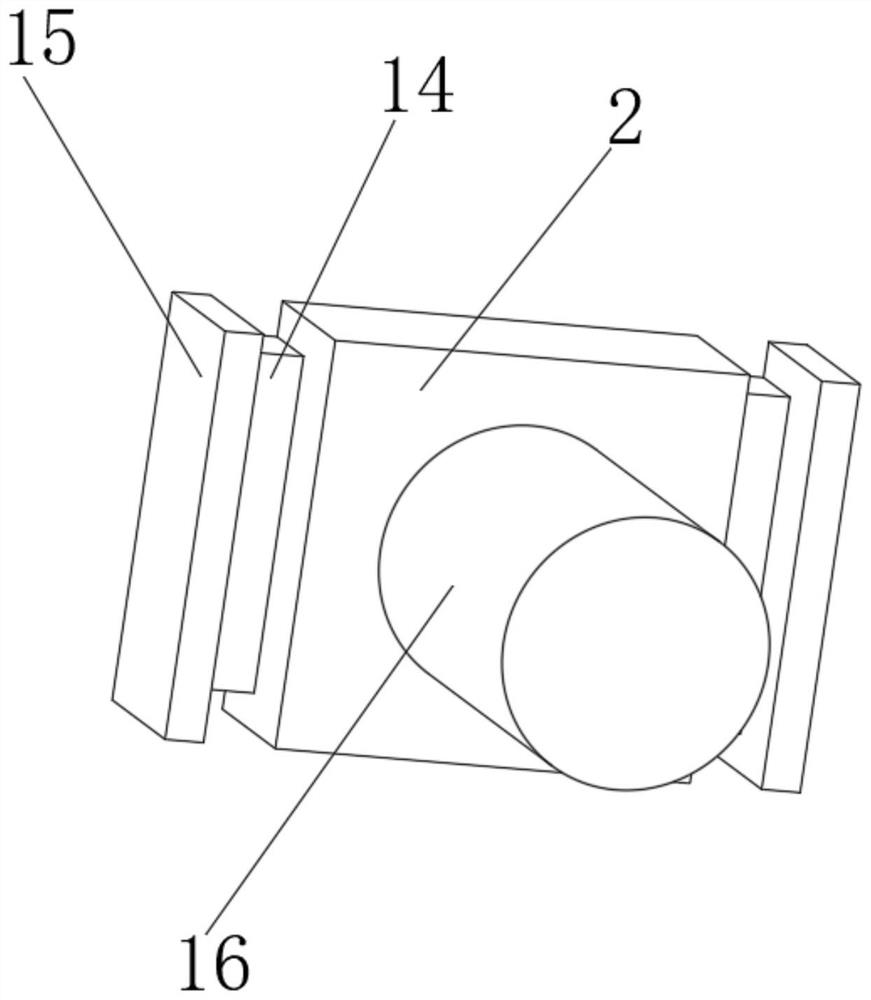

[0025] refer to Figure 1-3 , a soft package power lithium battery defect welding structure, including a battery body 1, the front end of the battery body 1 near the center is respectively provided with sealing grooves 17 on both sides, the two sets of sealing grooves 17 are symmetrical about the central axis of the battery body 1, and the battery body Four sets of sliding grooves 4 are provided on both sides of the interior of the battery 1, and the four sets of sliding grooves 4 are symmetrical to the central axis of the battery body 1 in pairs.

[0026] The center of the inner wall of the left end of the sealing groove 17 is fixedly connected with an ablation sheet 13, the right end of the sliding groove 4 runs through the left end of the sealing groove 17, and the center of both ends of the sealing groove 17 is respectively provided with an engaging groove 5, and two sets of engaging grooves 5 are related to the sealing groove 17 central axes are symmetrical; the inside of...

Embodiment 2

[0031] refer to Figure 4 , a soft package power lithium battery defect tab welding structure, the specific steps of the welding method are as follows:

[0032] The damaged tabs have been removed by opening the engaging frame 3: the staff presses the horizontal block 9, and the engaging block 10 moves in the movable groove 6 driven by the horizontal block 9. At the same time, the spring 8 contracts under the force, and the engaging block 10 leaves the engaging groove 5, pulls the engaging frame 3 to a certain position, and removes the nickel sheet 2 and the fixed tab 16 with an external tool.

[0033] Heating the ablation sheet 13 to replace the nickel sheet 2: heating the ablation sheet 13 inside the sealing groove 17 by low-power laser ablation to generate a welding surface with a suitable area, and putting the nickel sheet 2 into the sealing groove 17, Simultaneously push the engaging frame 3, press the horizontal block 9, the engaging block 10 enters the movable groove 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com