Auxiliary recognition method for gas turbine hole inspection component based on virtual reality technology

A technology of virtual reality technology and recognition method, which is applied in the field of non-destructive testing, and can solve problems such as the inability to quickly identify component structures and assembly features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

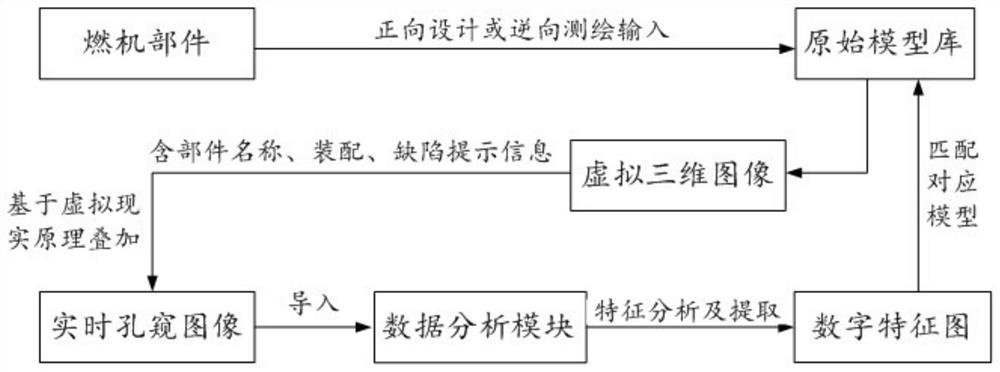

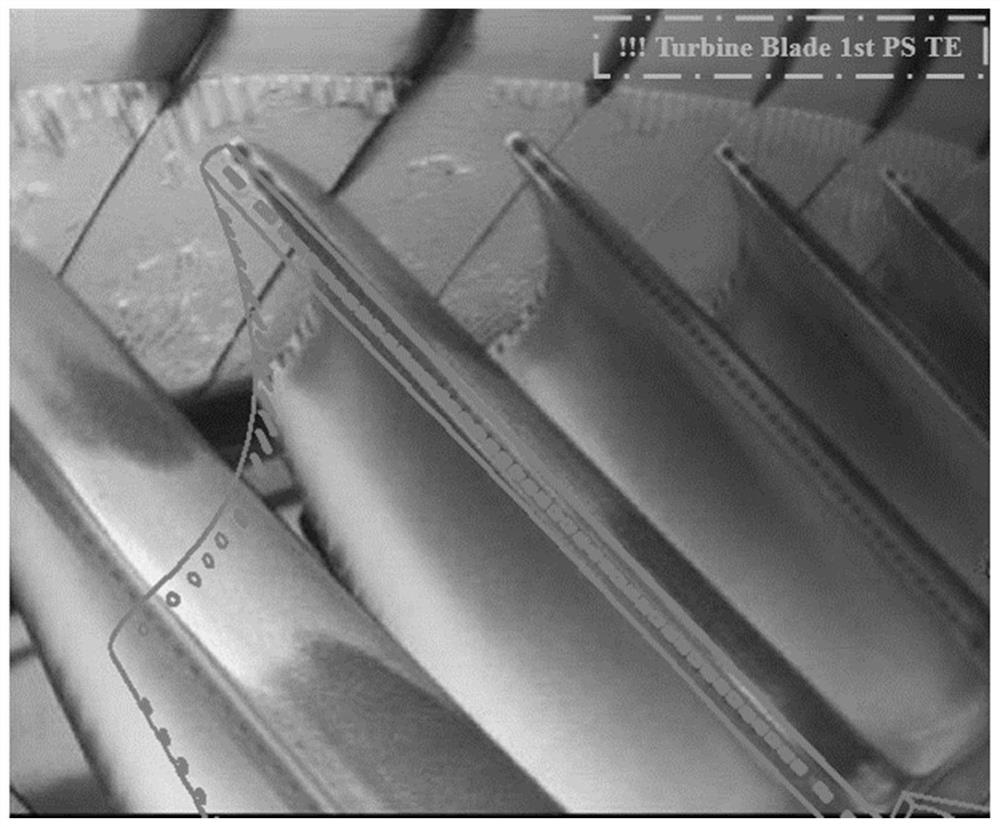

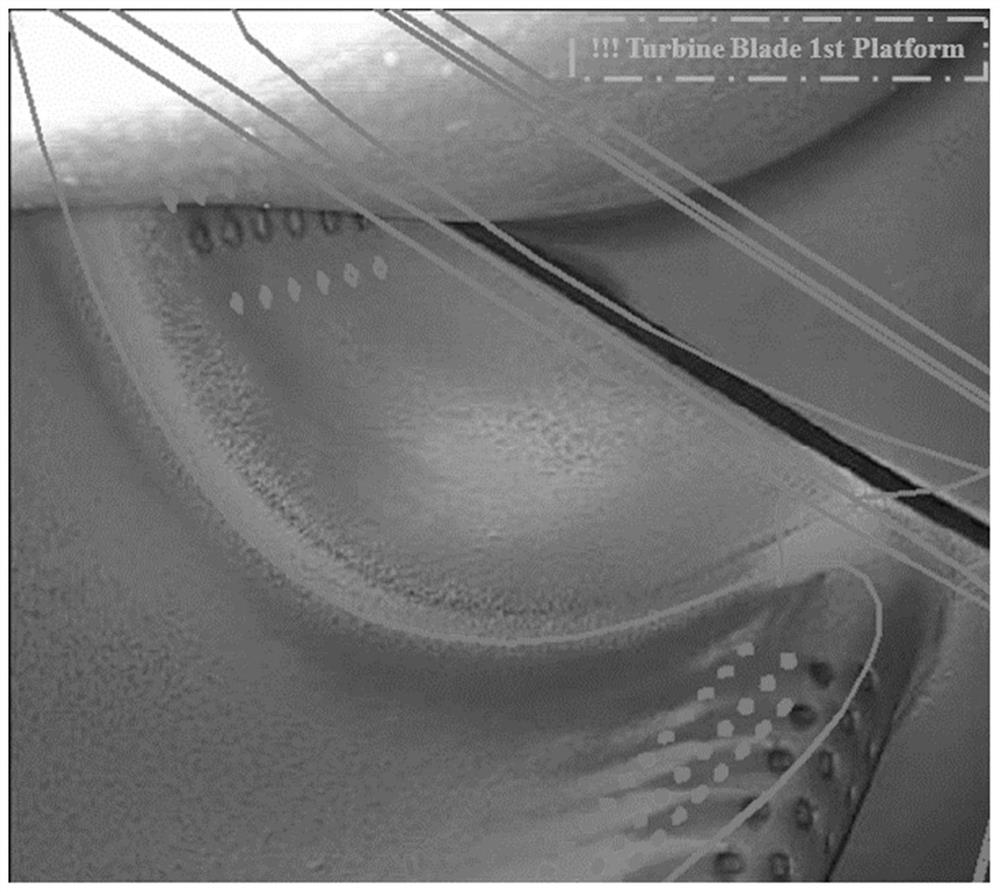

[0027] Refer to the attachment figure 1 A flow chart of a auxiliary identification method provided by a virtual reality technique of a virtual reality technology, wherein the characteristics are processed in the following steps:

[0028] Step 1: Generate the original model library in the shape and assembly data of the combustion engine component and assembly of the forward design or reverse mapping;

[0029] Step 2: Import analysis module in real-time pylo image data when the actual aperture inspection of the combustion engine is introduced;

[0030] Step 3: Characteristic analysis and extraction of components in the analysis module, generate digital characteristics;

[0031] Step 4: According to the digital characteristics, the corresponding model map is matched from the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com