Multi-material-roll pole piece unwinding device

A technology of unwinding device and pole piece, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of restricting unwinding, long time consumption, low efficiency, etc., so as to improve processing efficiency and reduce labor workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

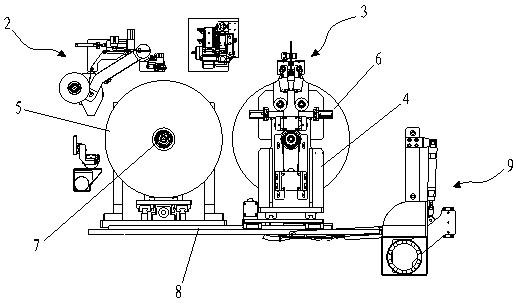

[0031] see figure 1 , the embodiment of the present invention provides a multi-roll pole piece unwinding device, including a roll preparation position 5, an unwinding position 6, a pole roll automatic tearing barcode device 2, a pole roll automatic exchange roll device 3 and a pole roll handling mechanism 4 , the roll preparation position 5 and the unwinding position 6 are close to each other, the middle part of the roll preparation position 5 and the unwinding position 6 protrudes from the suspension shaft 7 for hanging the pole roll, and the pole roll automatic tearing barcode device 2 is used for the roll preparation position 5 The barcode of the coil head of the new pole roll on the top is torn off, the pole roll handling mechanism 4 is movably set between the roll preparation position 5 and the roll unwinding position 6, and the pole roll supply is set under the roll preparation position 5 and the roll unwind position 6 The conveying track 8 on which the conveying mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com