LED lamp

An LED lamp and housing technology, applied in the field of lighting, can solve the problems of people stepping on, scratches on hard objects, damage to the insulation of the power supply line, and easy induction of electric shock accidents, so as to prevent accidental electric shock accidents, reduce waste of mains power, and improve The effect of power supply security and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

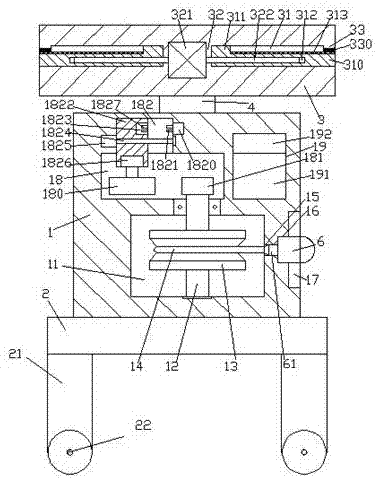

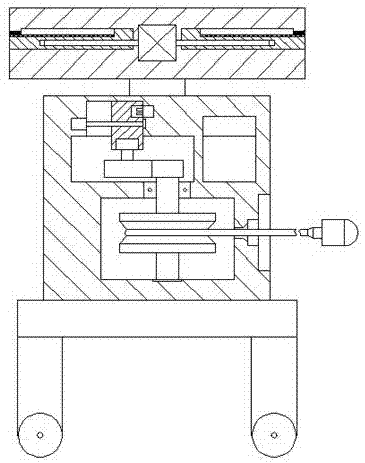

[0022] Such as Figure 1-Figure 4 As shown, an LED lamp of the present invention includes a housing 1 fixed on the top of the machine base 2 and a ceiling 3 arranged above the housing 1. A cavity 11 is provided in the housing 1, and the cavity The housing 1 at the top of the cavity 11 is provided with a first transverse cavity 18 and a second transverse cavity 19, the inner top wall of the first transverse cavity 18 is provided with a sliding groove 182, and the cavity 11 on the right side The outer wall of the housing 1 is provided with a pick-and-place slot 17, and a passage slot 15 and an engaging slot 16 are provided between the pick-and-place slot 17 and the cavity 11, and the cavity 11 is provided with a vertically extending The revolving pin shaft 12, the top extension section of the revolving pin shaft 12 passes through the inner wall of the housing 1 and enters the first transverse cavity 18, the tail end of the revolving pin shaft 12 in the first transverse cavity 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com