Controller and upper cover plate NVH performance optimization structure

A technology that optimizes structure and controller, applied in electrical components, chassis/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, etc., can solve problems such as poor NVH performance, prolong service life, increase Stable, modal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

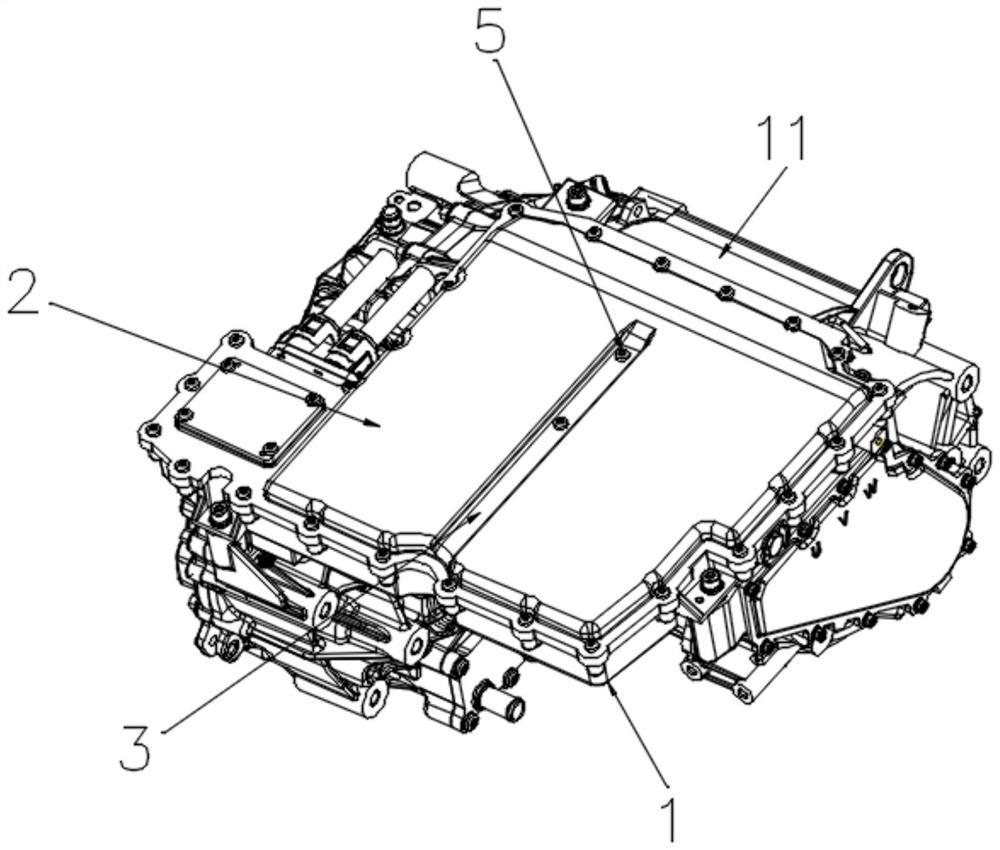

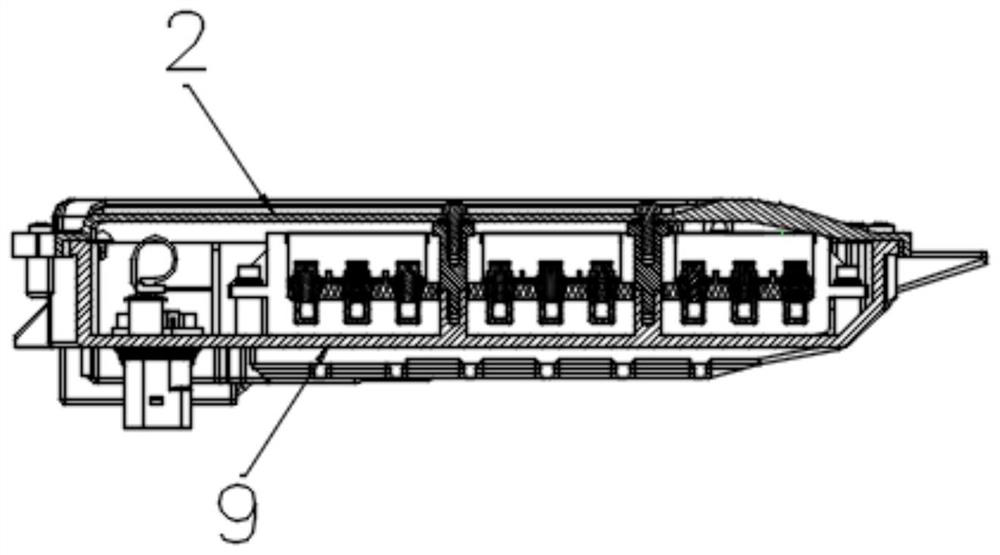

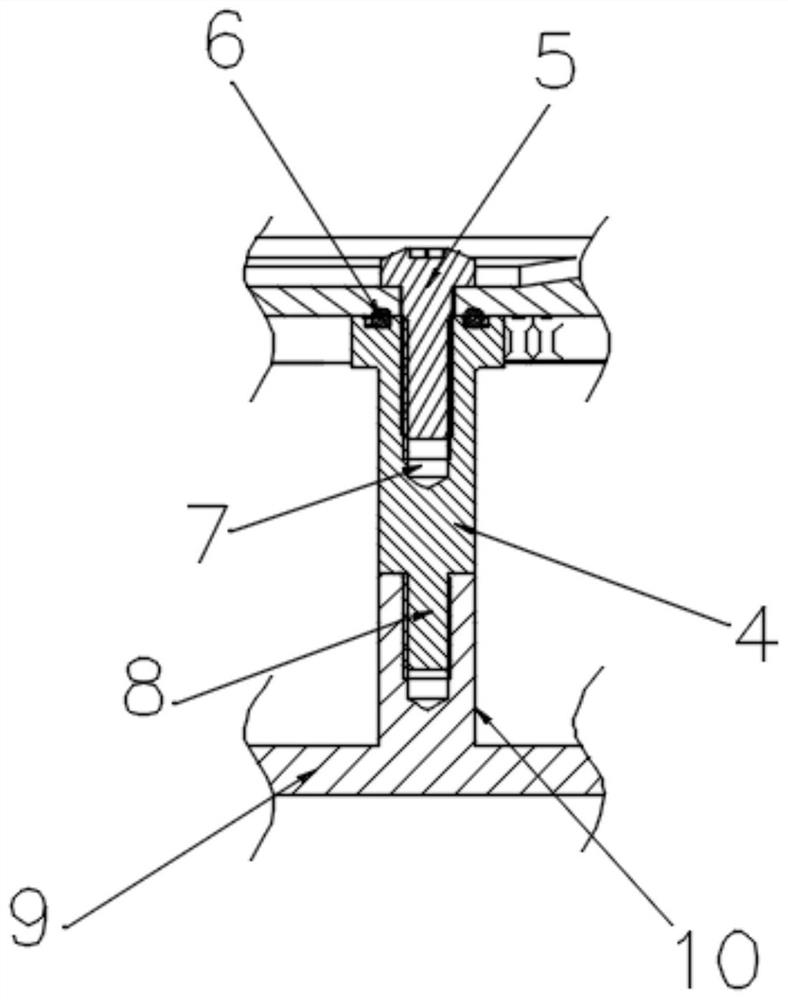

[0040] figure 1 It is a structural schematic diagram of the NVH performance optimization structure of the upper cover plate of a controller proposed by the present application; figure 2 is the schematic diagram of the cross-sectional structure of the shell; image 3 It is a schematic diagram of the connection structure of the transfer stud and the bolt. A NVH performance optimization structure of an upper cover of a controller may include: a controller 1 , an upper cover 2 , a groove 3 , a fixing component, a housing 9 , and an installation area.

[0041] The groove 3 is located on the upper cover plate 2, the installation area is located in the groove 3, the fixed component is installed in the installation area, and the installation area is set to be a rectangle, a circle center, an ellipse, etc., and the center position of the installation area is the same as the upper cover plate The center positions of 2 coincide, so that the lowest modal position of the upper cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com