Advanced operation method for rapid lifting of mining heavy truck

A technology of heavy-duty vehicles and operation methods, which is applied in the direction of tilt-bearing vehicles, etc., can solve the problems of inaccurate dumping space, inaccurate dumping of goods, insufficient dumping angle, etc., to reduce safety hazards and time, and avoid diesel fuel. Wasteful, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

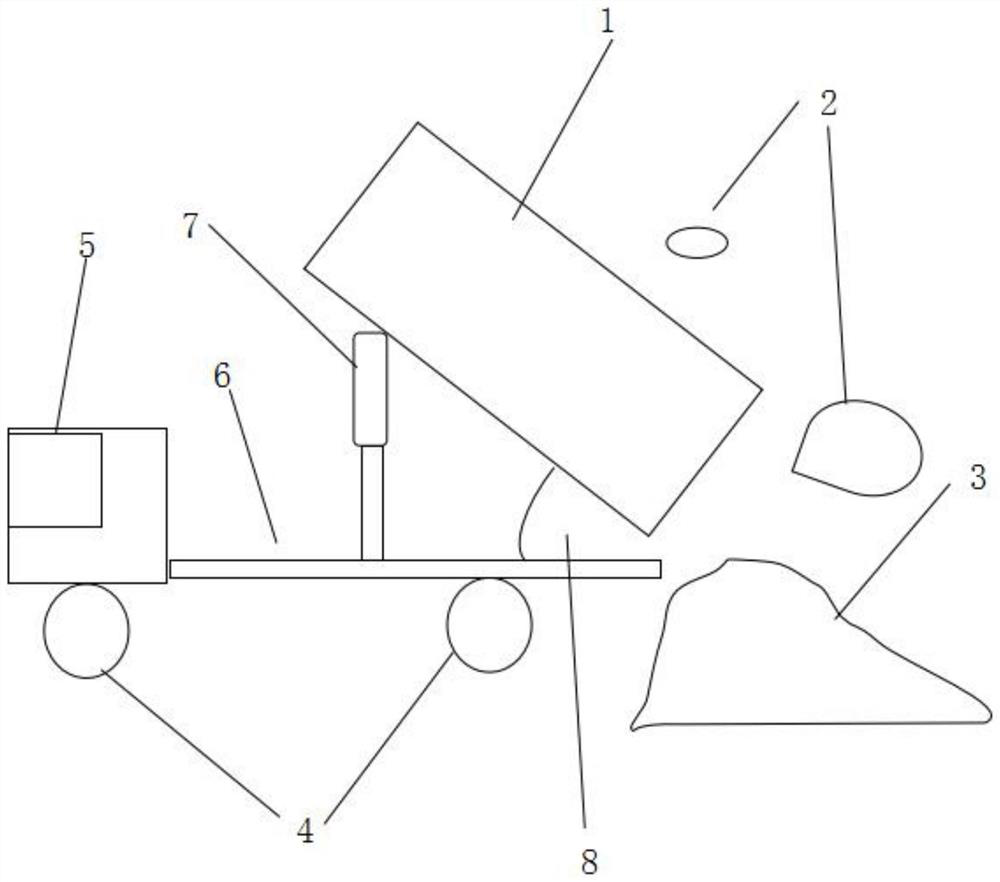

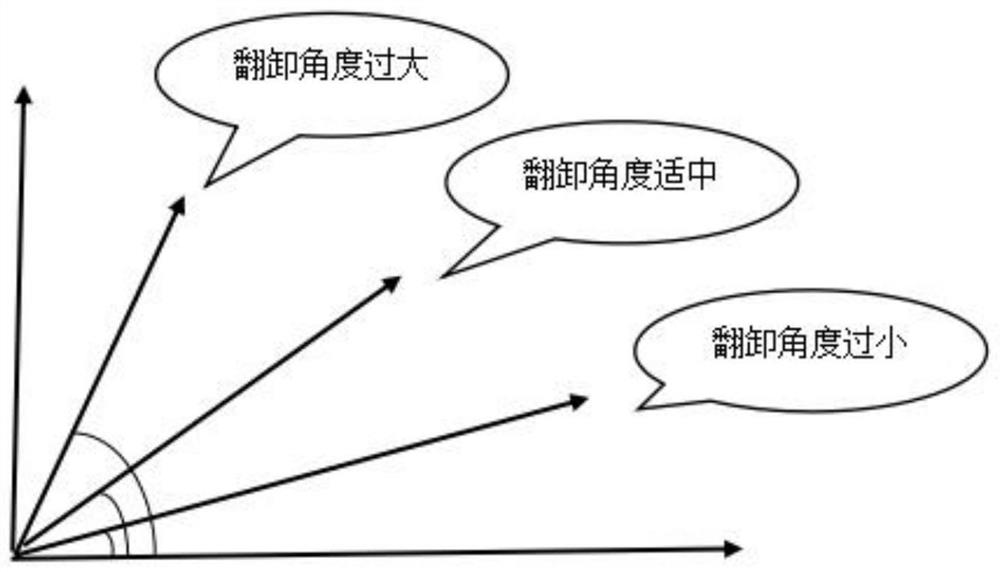

[0040] Such as figure 1 and 2 As shown, an advanced operation method for fast lifting of heavy-duty trucks for mining, the specific steps are as follows:

[0041] Step 1: Confirm in advance: When entering the dumping site, the speed of the vehicle is not greater than 10 km / h. The position of the dumping sign must be confirmed. After turning around, use the dumping sign as a reference to carry out reversing operations. Without the dumping sign, operations are prohibited. The dumping sign is a red and white iron frame with a red flag on it during the day and a flashing red light at night. When special operations are done on natural slopes, the command signal is: red and green signal flags during the day, the green flag swings left and right for reversing; A yellow flag during the day and a yellow light at night indicate a natural slope, and vehicles should be dumped 10 meters away from the edge of the cliff.

[0042] Step 2: Observation: When the mining vehicle arrives at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com