Maintenance tool for nuclear-grade electric ball valve

An electric ball valve and tooling technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as high requirements for personnel collaboration and workability, and achieve the effect of saving the number of operators, solving small space, and preventing over-torque damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

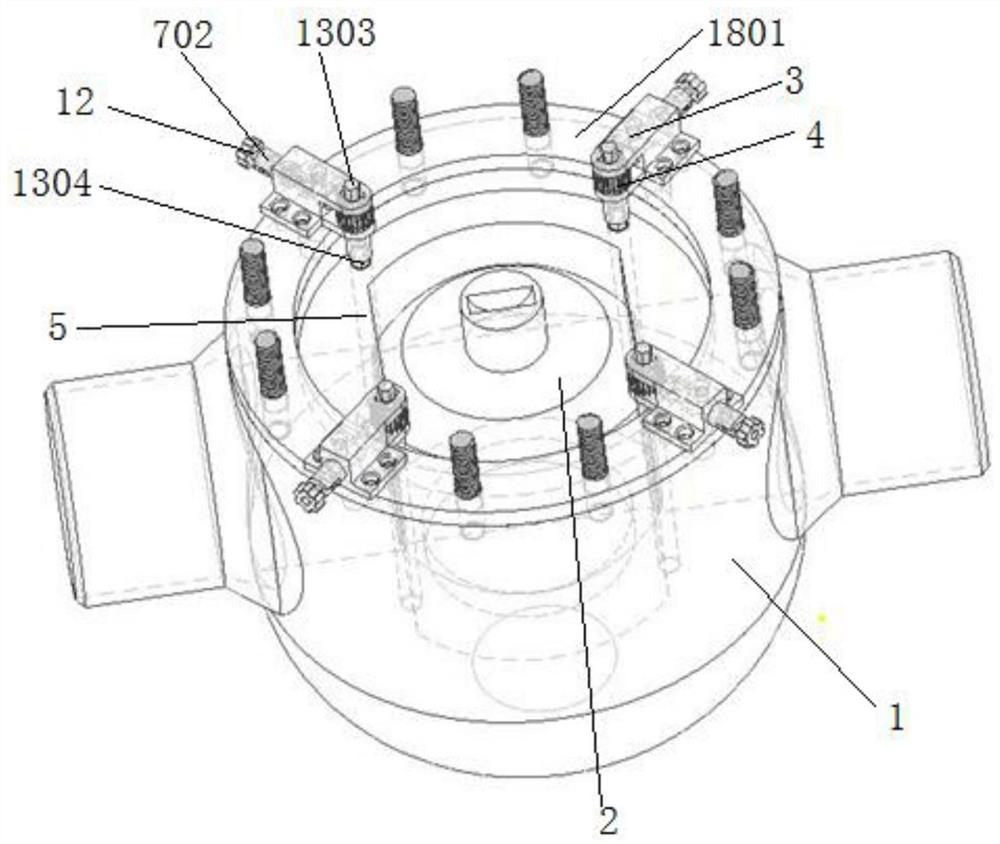

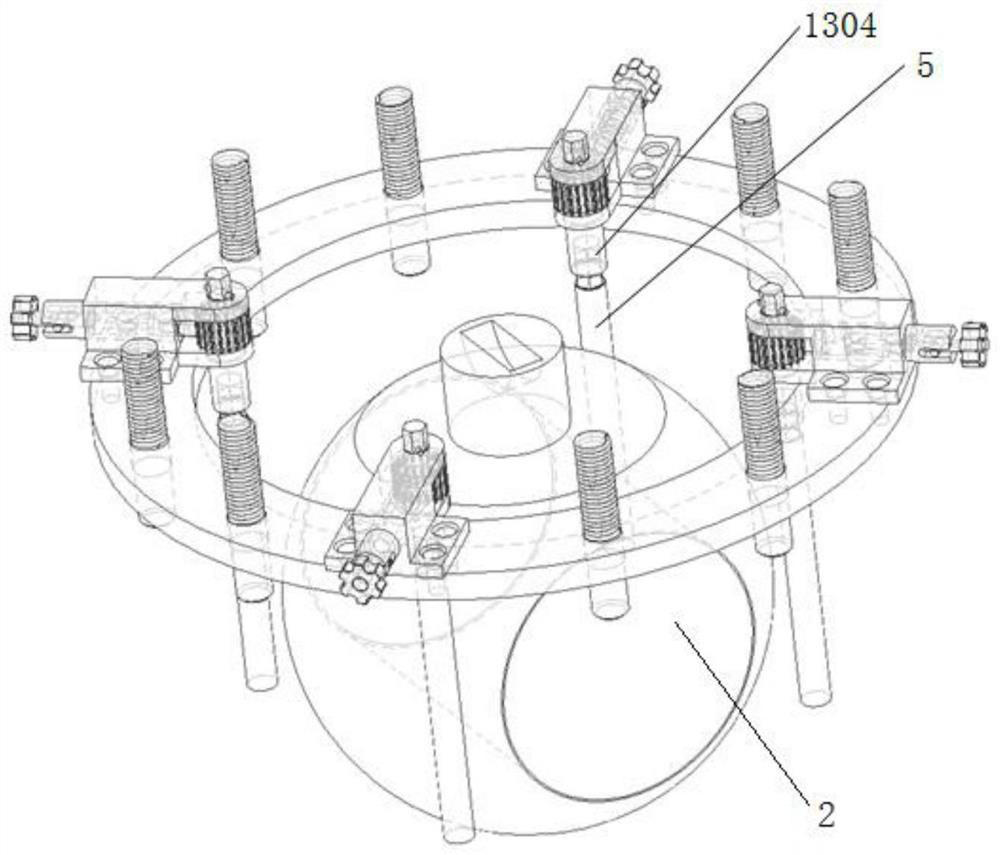

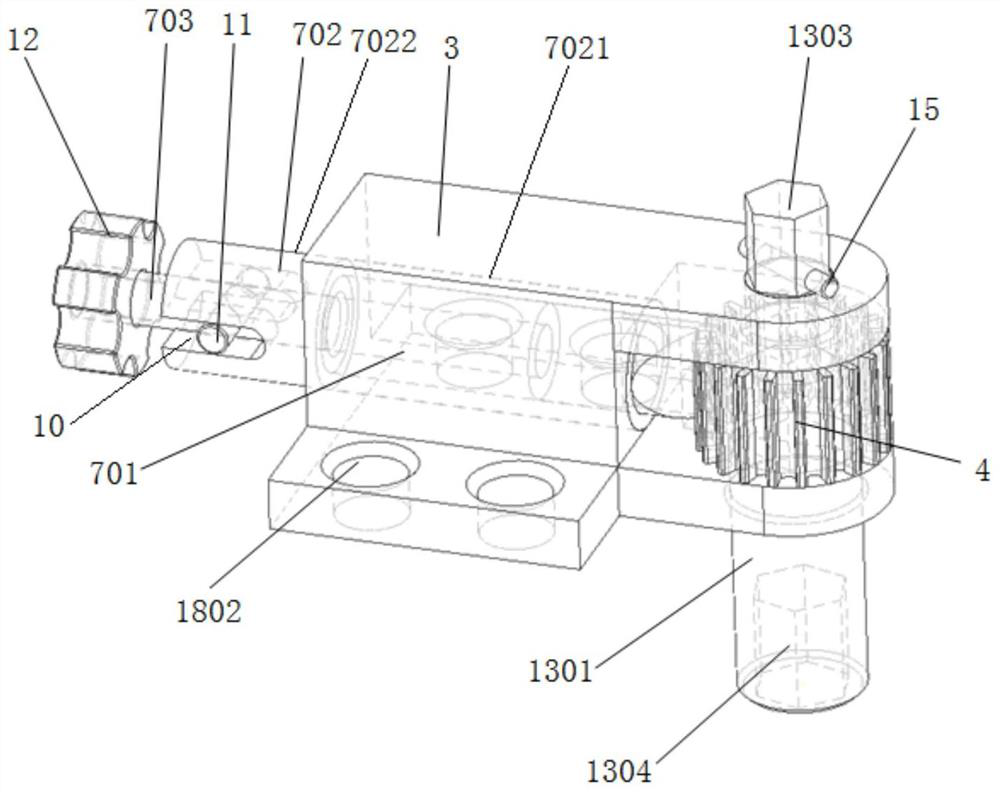

[0047] A maintenance tool for nuclear-grade electric ball valves, including:

[0048] Fixing mechanism, the fixing mechanism is fixedly connected to the valve seat of the electric ball valve;

[0049] The base 3 is fixed on the fixing mechanism;

[0050] Rotary mechanism, the rotary mechanism is rotatably connected to the base 3, the rotary mechanism includes:

[0051] The rotating part 4 is used to drive the adjusting rod 5 of the electric ball valve to rotate when rotating;

[0052] Locking mechanism, the locking mechanism is arranged on the base 3, and the locking mechanism includes:

[0053] The locking member 6 is used to lock the rotating member 4 so that the rotating member 4 stops rotating;

[0054] A locking drive assembly, the locking drive assembly is connected to the locking member 6, and is used to drive the locking member 6 to be inserted into the rotating member 4 to form a locked state;

[0055] Wherein, when the rotating member 4 rotates in the first direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com