Method for installing low-voltage cable transformation platform

An installation method and low-voltage cable technology, which are applied in the field of transformer tables, can solve problems such as large manpower consumption, low gravity of utility poles, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

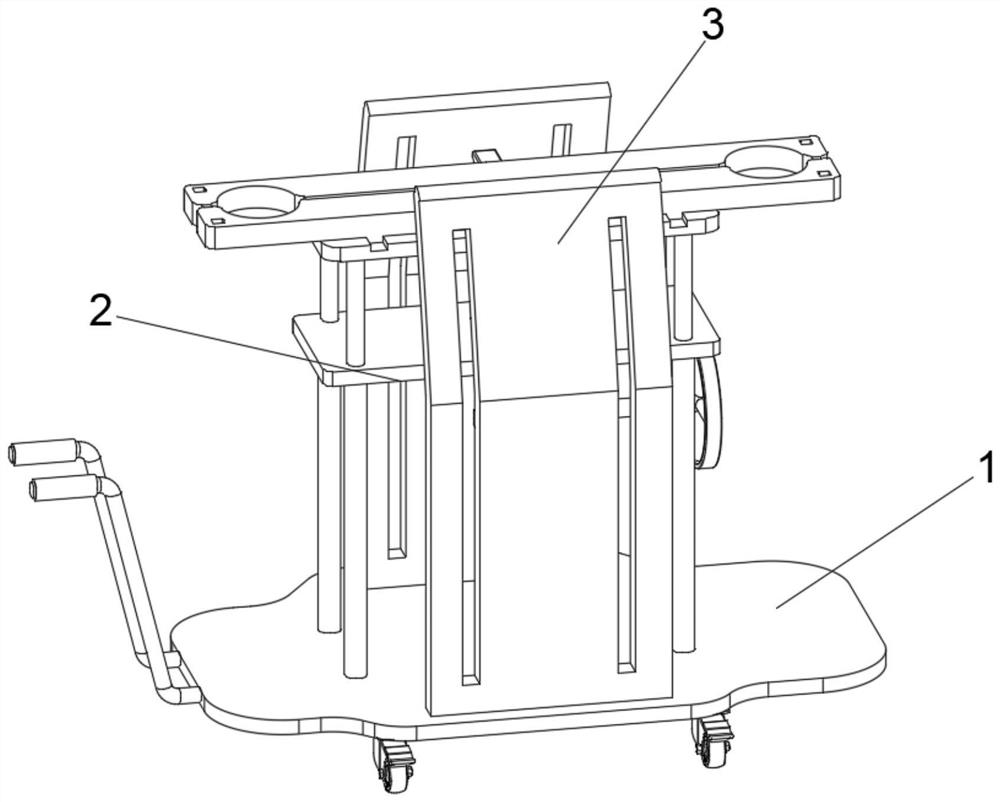

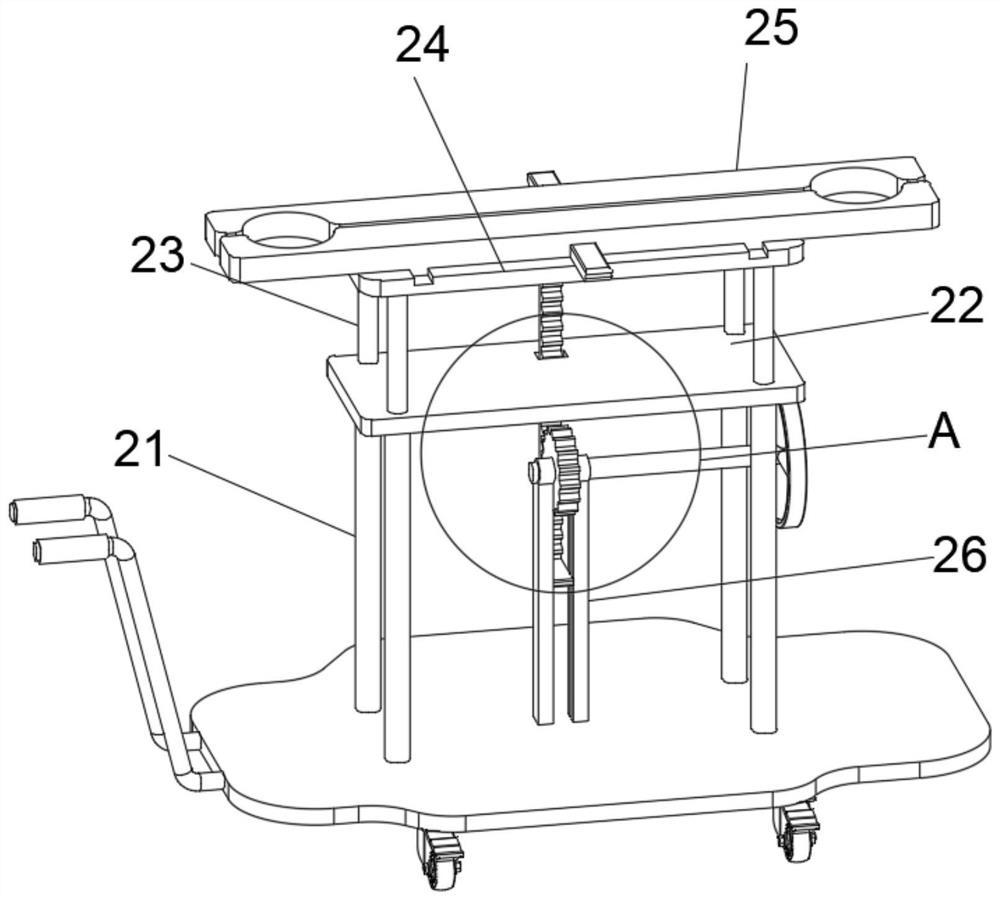

[0045] see Figure 1-Figure 6 As shown, the purpose of this embodiment is to provide a low-voltage cable transformer installation method, which specifically includes the following steps:

[0046] S1. Push the supporting element between the two utility poles;

[0047] S2. Place the two single transformer tables oppositely on the supporting block of the supporting element. The transformer table and the two utility poles are located between the two transformer tables, and are at the same level as the arc opened on the surface of the transformer table. horizontal line;

[0048] S3. The support element is normally driven, and the upward movement of the carrier block makes the transformer table be driven upward synchronously, and the transformer table moves upward along the surface of the utility pole. When the height from the ground is reached, the support element stops working;

[0049] S4. Push the two transformer tables relative to each other, the arc on the surface of the tra...

Embodiment 2

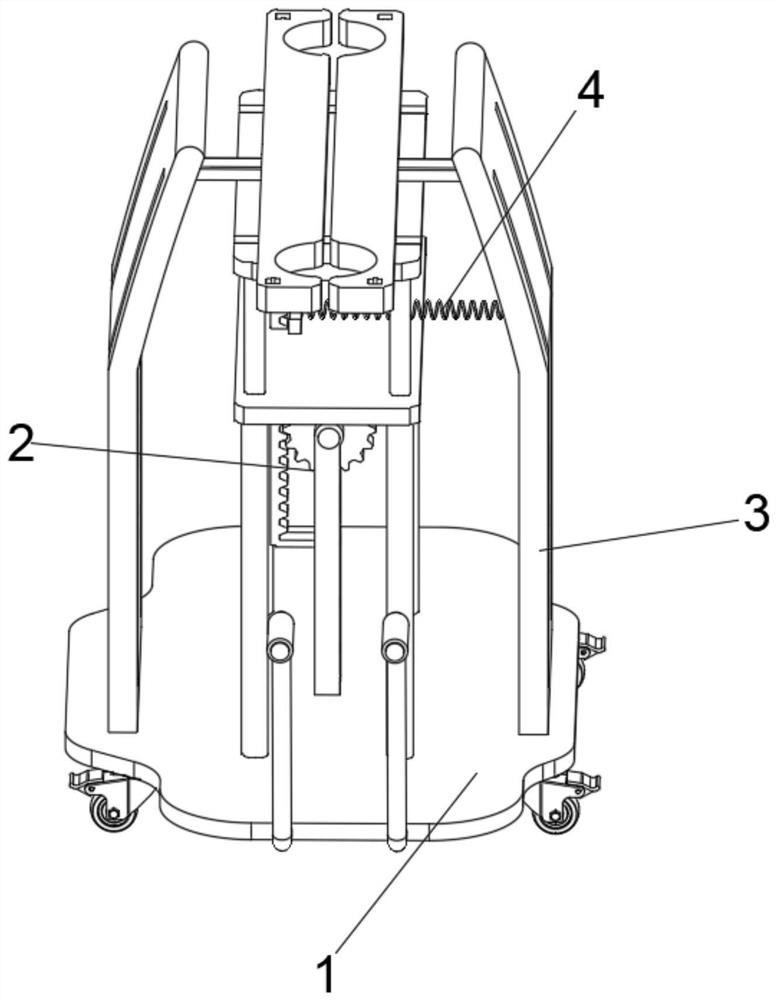

[0057] In order to prevent the platen body 25 from being overturned sideways due to the extrusion force of the side guide block 253, please refer to Figure 7 and Figure 11 Shown:

[0058] The inner side of the jacking assembly 2 is provided with a limit assembly 5, the limit assembly 5 includes a connecting shaft 51, the connecting shaft 51 is installed on the other side of the shaft, and one end of the connecting shaft 51 is equipped with a connecting gear 52, and the surface of the connecting gear 52 is engaged A connecting rack 53 is connected, and a connecting plate 57 is installed on the side of the connecting rack 53. One side of the connecting plate 57 is provided with a circular cavity, and one of the outer fixed shafts 21 is socketed with the circular cavity, and the top of the connecting rack 53 is connected Limiting plate 54, and limiting plate 54 is positioned at the directly below platen body 25, and the surface of limiting plate 54 is provided with the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com