Fabricated supporting system for medical building

A support system and prefabricated technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problem of inconvenient to support wall panels, and achieve the effect of improving the scope of application and improving the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

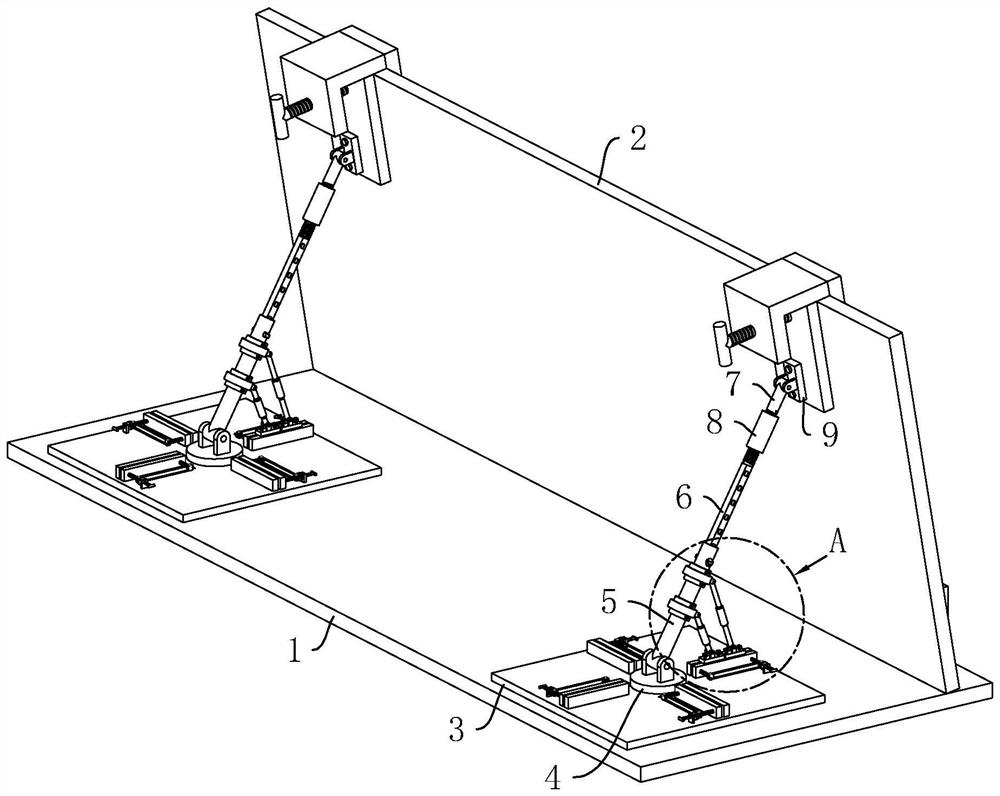

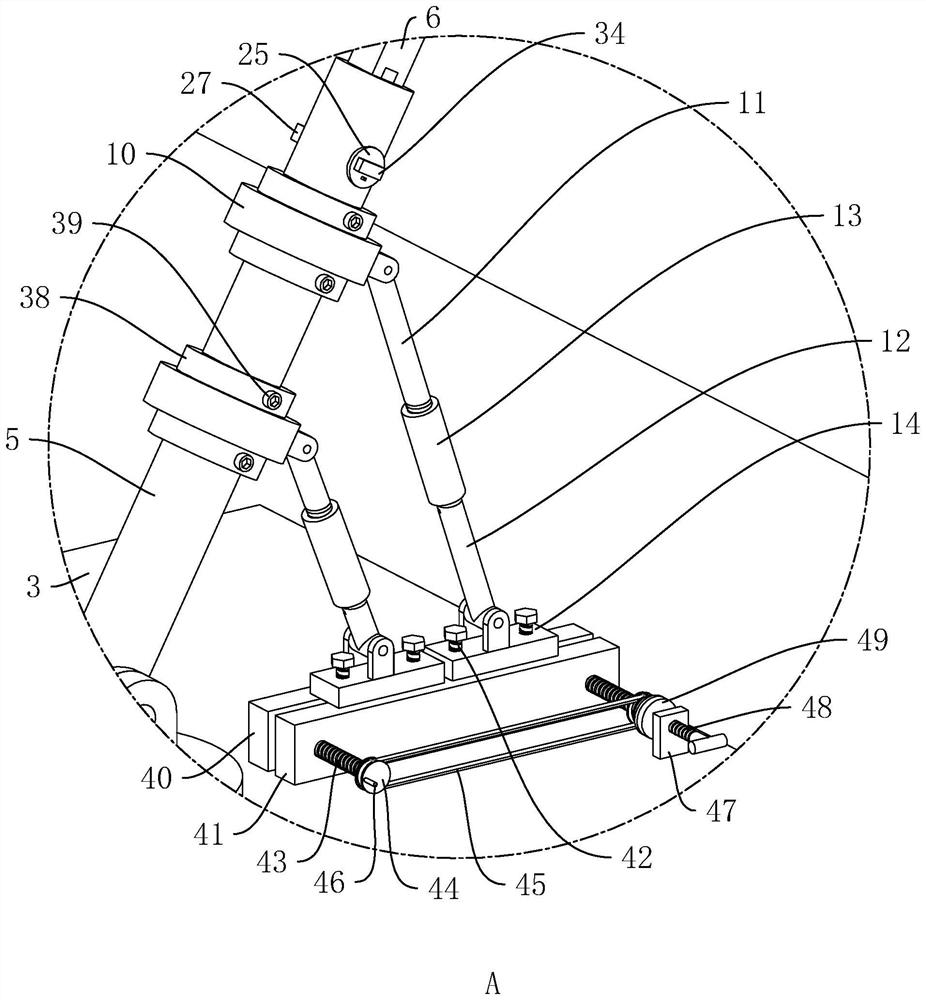

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] The embodiment of the present application discloses a prefabricated support system for medical buildings.

[0039] refer to figure 1 , a prefabricated support system for a medical building, comprising a plurality of base plates 3 and a plurality of limiting components clamped at the edge of the floor plate 1 . The bottom plate 3 is rotatably connected with a circular steering block 4, a cylindrical support rod 5 is hinged at the center of the steering block 4 and a first shaft is hinged between the support rod 5, and the axial direction of the first shaft is arranged along the horizontal direction. The support rod 5 is slidably connected with a rectangular telescopic rod 6 along the length direction of the support rod 5 . The support rod 5 is provided with a support groove (not shown in the figure) along the direction away from the steering block 4. The telescopic rod 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com