Discharge apparatus

A discharge device, installation state technology, applied in the direction of injection device, distribution device, liquid injection device, etc., to achieve the effect of stable installation state, suppression of original liquid leakage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

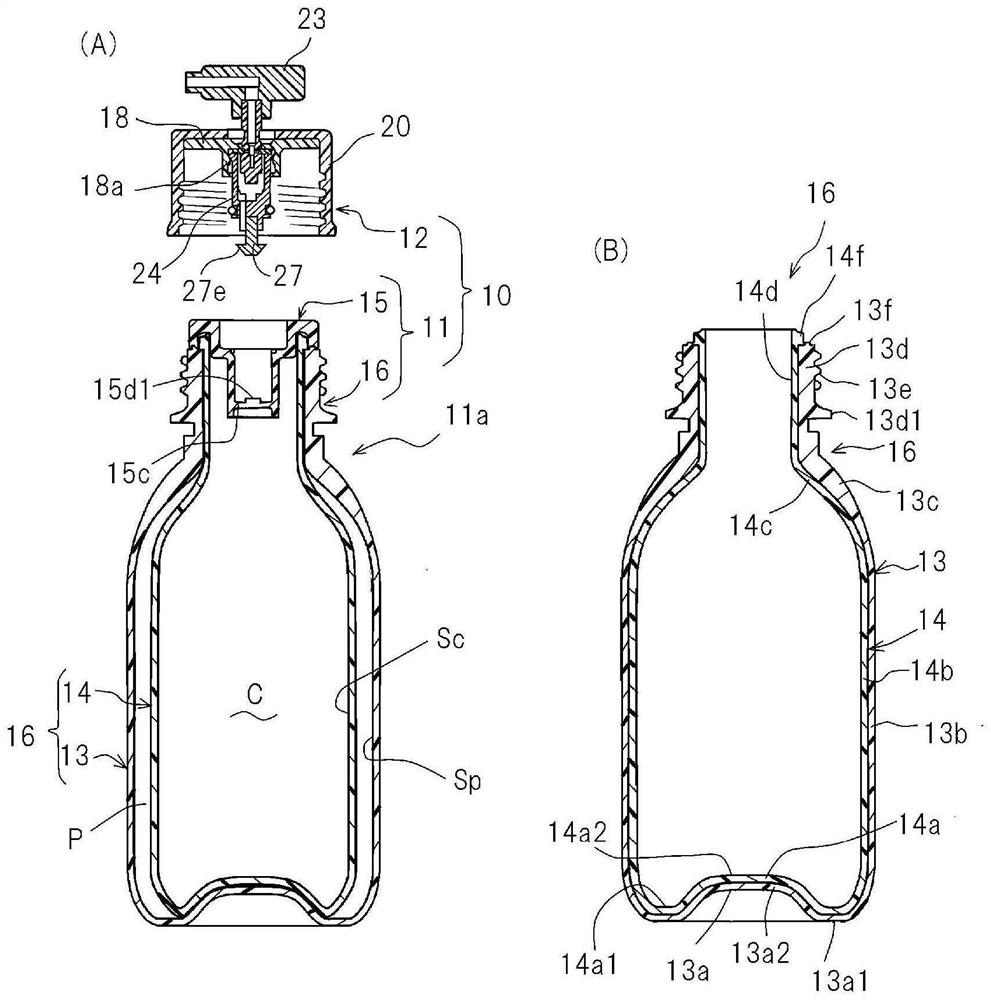

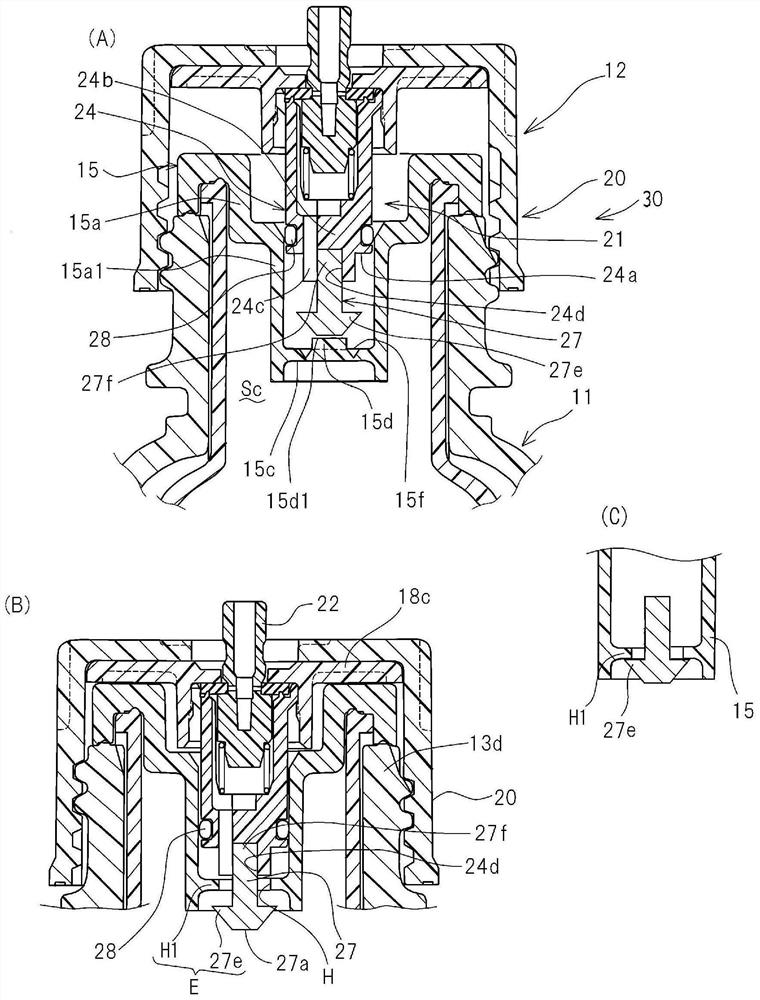

[0076] figure 1 The discharge device 10 shown in (A) is composed of a double pressurized container (container) 11 , a discharge member 12 , an undiluted solution (content) C and a pressurizing agent P filled in the double pressurized container 11 . The product filled with the undiluted solution C and the pressurizing agent P in the double pressurized container 11 is the pressurized product 11a. The pressurized product 11a and the discharge part 12 are pre-assembled as a complete set (refer to figure 1 (A)), or half-assembled in an unopened state (see image 3 (A)) for sale. The pressurized product 11a may be sold separately as a replacement instead of being sold together with the discharge member 12 . Therefore, the pressurized product 11a is hermetically sealed before the discharge member 12 is attached (unsealed by the discharge member 12) to prevent leakage of the filled stock solution C or pressurizing agent P. The discharge member 12 may also be sold separately.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com