Labor-saving opening and closing automatic door

A technology for automatic doors and door panels, applied in door/window accessories, wing openers, power control mechanisms, etc., can solve the problems of complicated installation, inability to install automatic door control devices, material waste, etc., and achieves low driving force requirements. The effect of saving effort to open the door and speeding up the speed of opening the door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

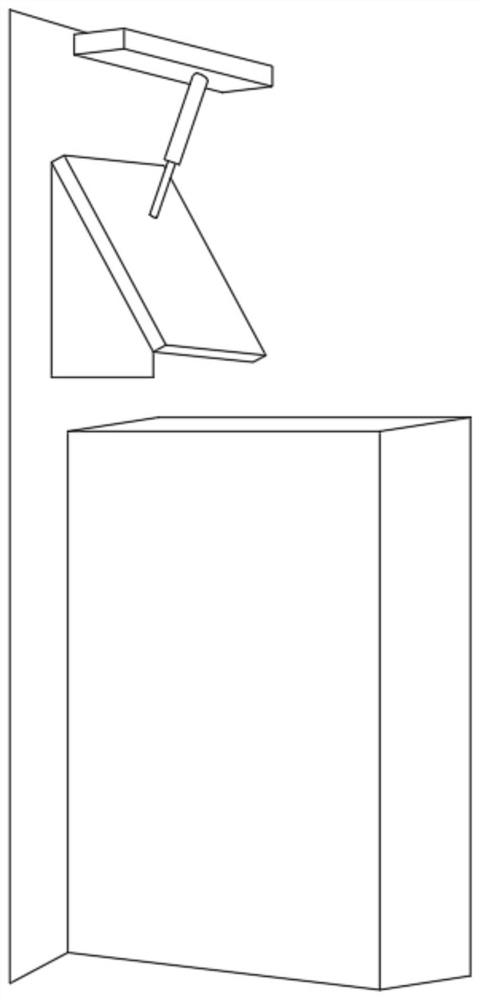

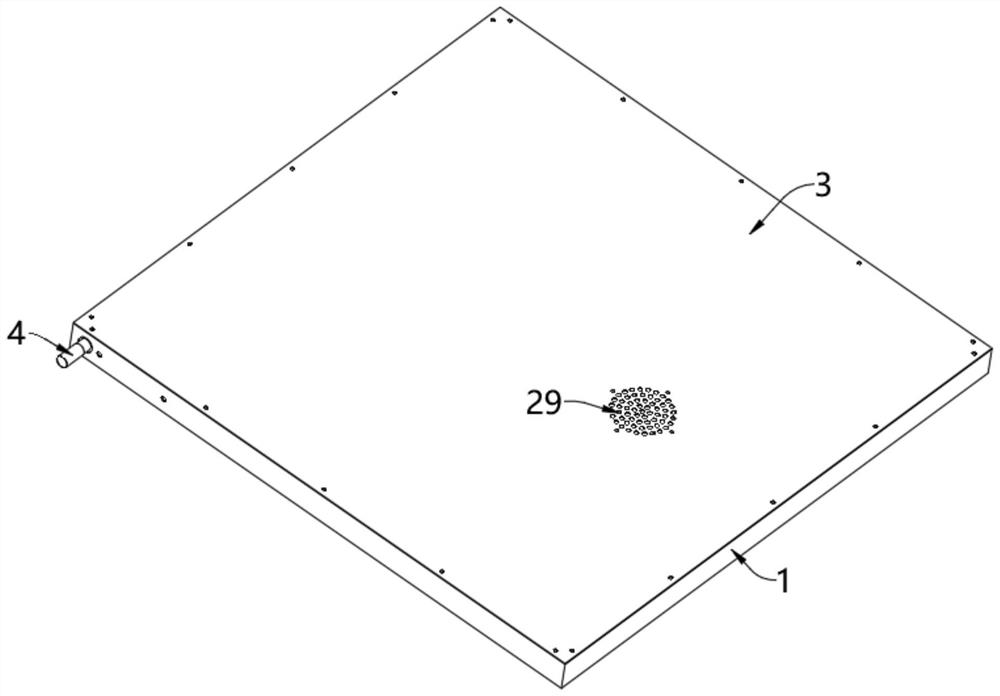

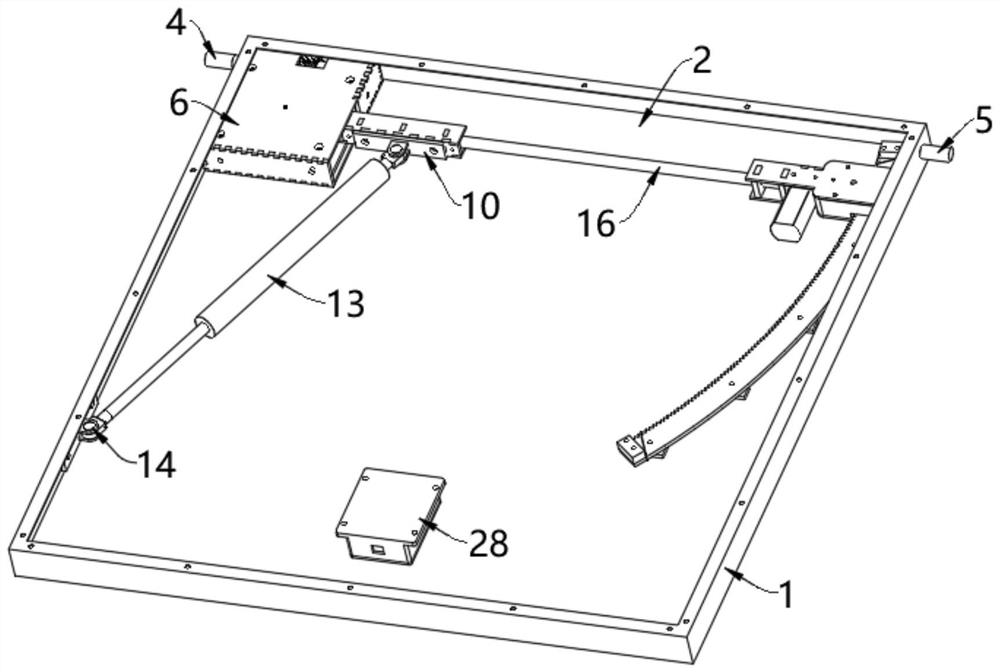

[0042] see Figure 1-Figure 9 , a kind of opening and closing labor-saving automatic door, comprising a door panel 1, the interior of the door panel 1 is formed with an inner cavity 2, and the opening of the inner cavity 2 is covered with a cover plate 3, and the cover plate 3 is used to close the inner cavity 2;

[0043] The drive cabinet 6 is fixedly installed at the corner of the inner cavity 2, and the inside of the drive cabinet 6 is rotated with a horizontal shaft 7. The end of the horizontal shaft 7 extends to the outside of the door panel 1 and is fixedly connected with the drive shaft 4. On one side of the door panel 1, the opposite side of the door panel 1 to the drive shaft 4 is fixedly equipped with a rotating shaft 5. During installation, the driving shaft 4 is fixedly arranged on the inner wall of one side of the door slot, and the rotating shaft 5 is rotatably arranged on the other side of the door slot. On the inner wall of one side, thus, the door panel 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com