Full-automatic frying machine

A frying machine, fully automatic technology, applied in the direction of conveyor objects, oil/fat baking, food ovens, etc., can solve the problems of easy sticking together when frying, slow frying output speed, inconvenient operation, etc. Achieve the effects of improving frying output efficiency, improving frying efficiency, and simplifying the frying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

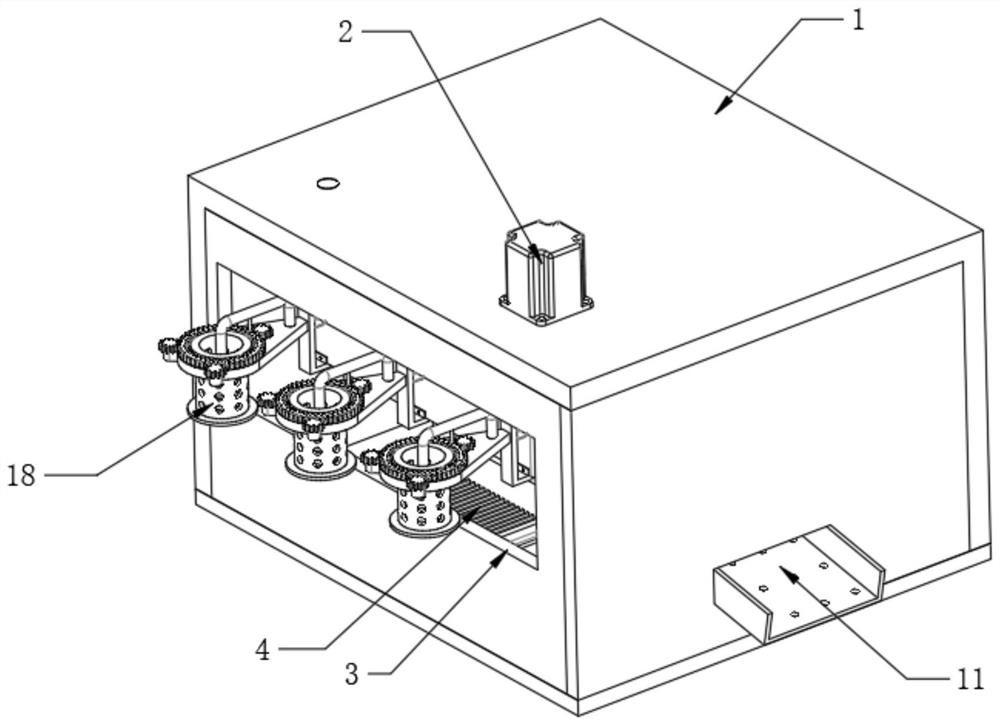

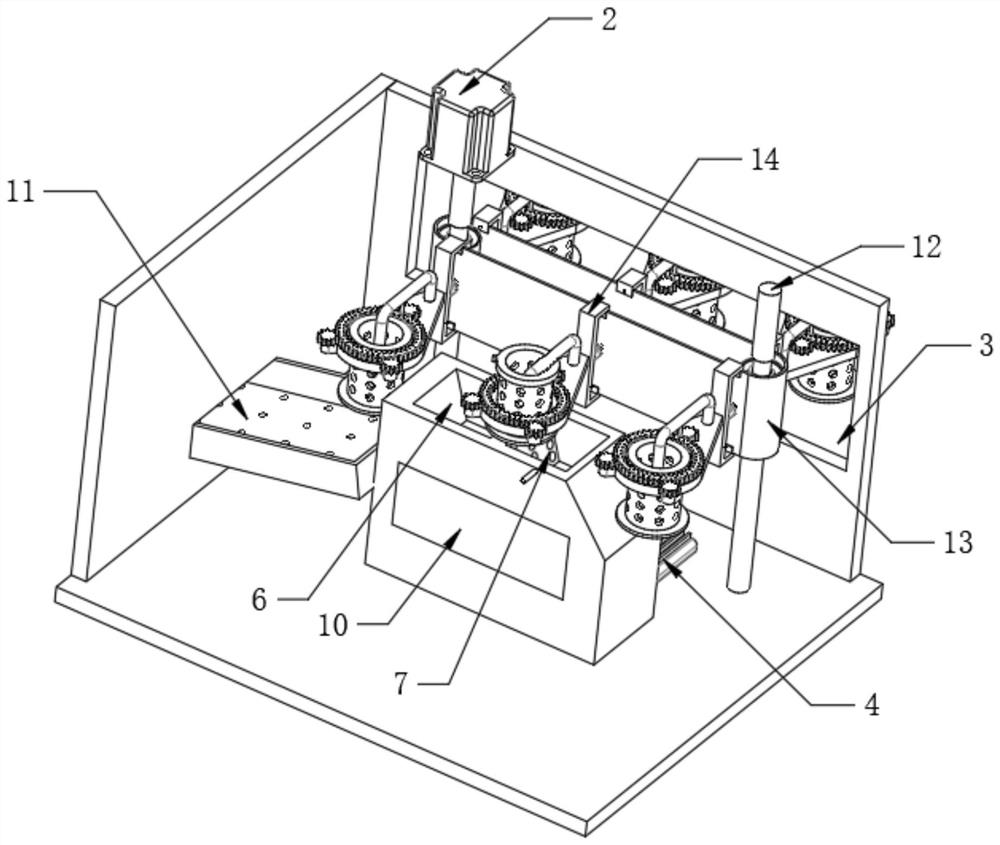

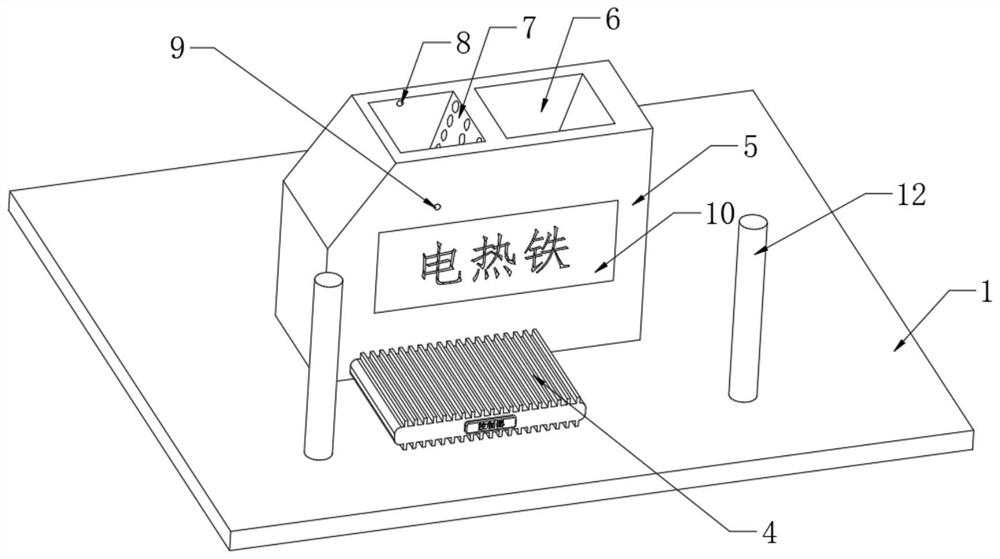

[0037] like Figure 1-7 As shown, in this embodiment, a fully automatic fryer is provided, which is composed of a casing 1, a conveying device, a discharging device, a frying device, a discharge chute 11 and a controller 4. Wherein box body 1 front side is provided with window 3, is convenient for discharging. The conveying device is arranged in the box body 1 and is close to the window 3. The feeding device includes a plurality of material barrels 18, and each material barrel 18 is installed on the conveying device through a turning mechanism. The material barrels 18 are used to put food to be fried , the conveying device can circulate a plurality of material barrels 18 on it, and the height of the material barrels 18 is 5-10cm smaller than the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com