A high-speed drive motor shaft for new energy vehicles

A technology of new energy vehicles and high-speed motors, applied in the direction of motors, electric vehicles, brake actuators, etc., can solve problems such as the influence of heat and centrifugal force bearings, achieve the effects of reducing impact force, preventing jamming, and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

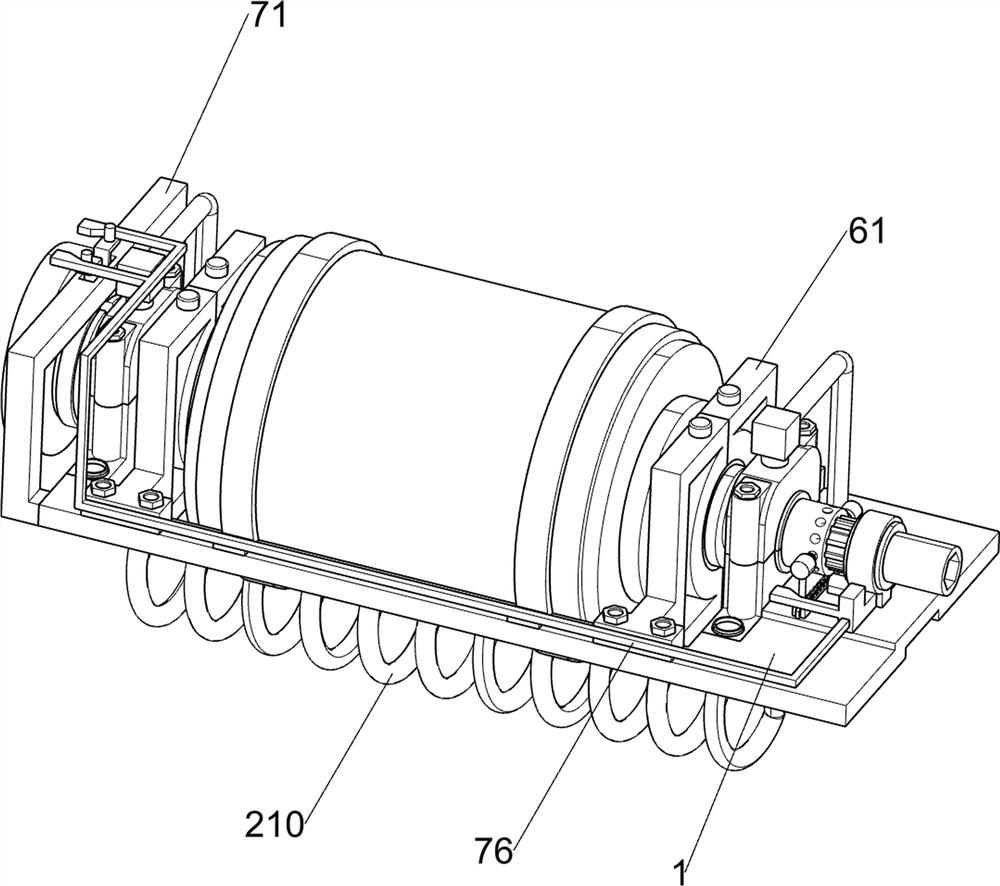

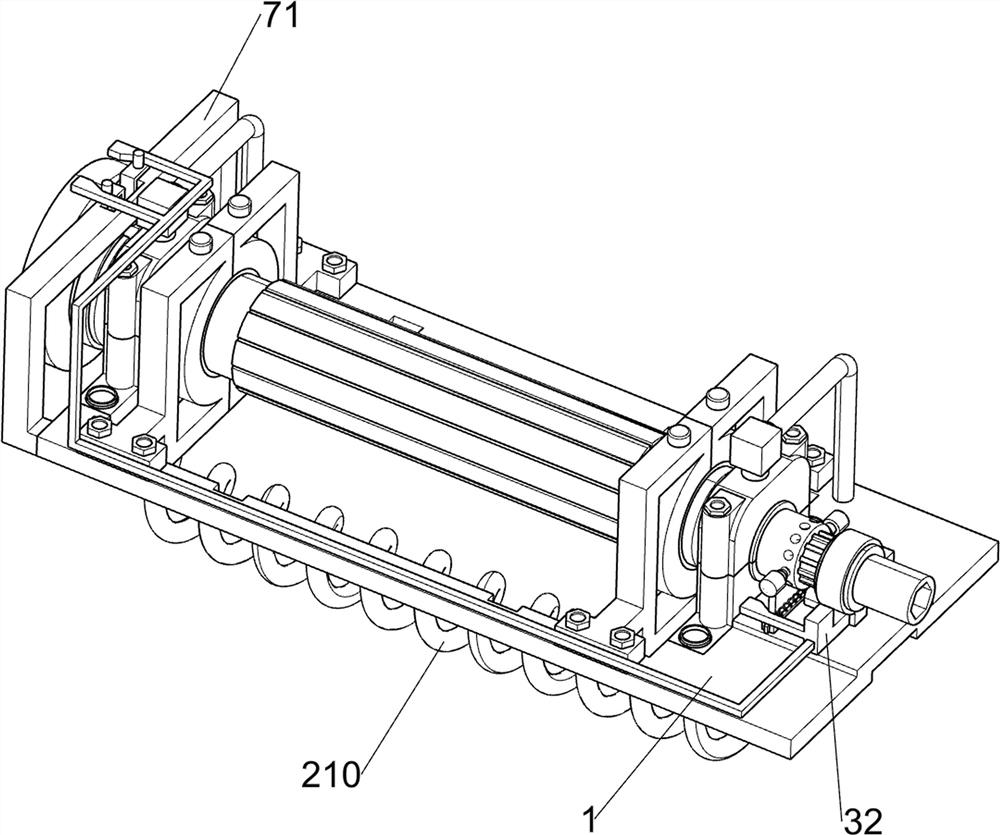

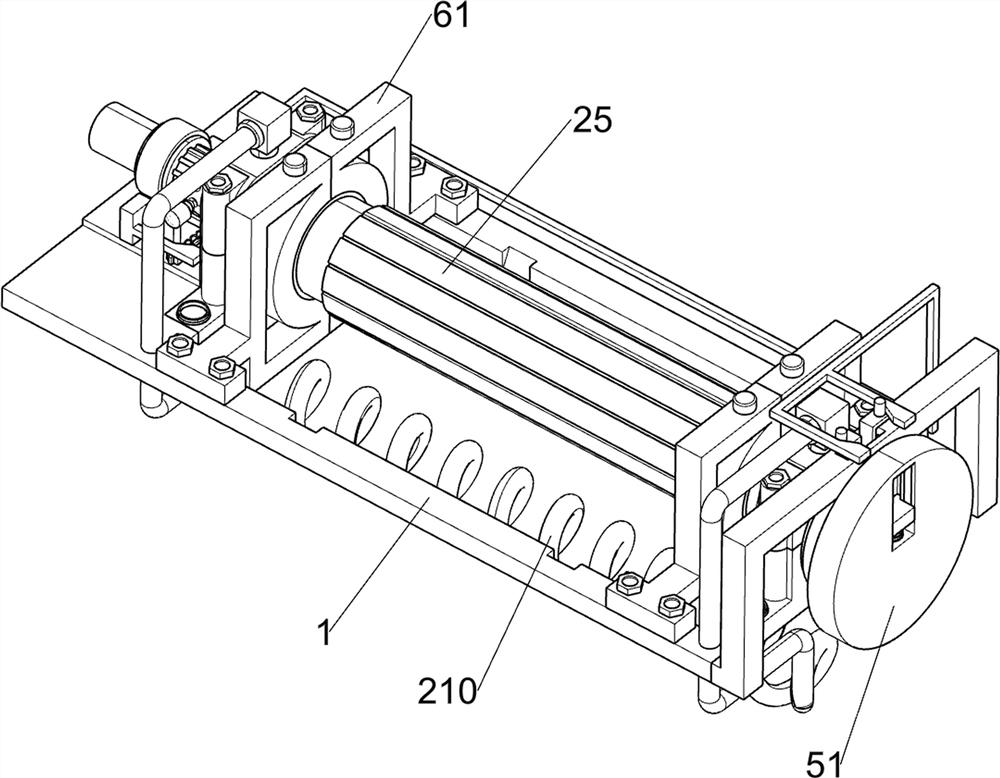

[0042] A high-speed drive motor shaft for a new energy vehicle, as shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9,

[0045] The position calibration component 4 includes a guide rail 41, a movable seat 42, a guide sleeve 43, a cylindrical clamping rod 44, a clamping spring 45 and

Embodiment 2

[0049] On the basis of Embodiment 1, as shown in Figure 14 and Figure 15, also includes a heat dissipation power adjustment component 5, the heat dissipation power

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com