Method for improving performance of high-carbon high-chromium wear-resistant and corrosion-resistant material

A corrosion-resistant material, high-carbon and high-chromium technology, applied in the field of performance improvement of high-carbon and high-chromium wear-resistant and corrosion-resistant materials, can solve the problems of inability to meet wear and corrosion resistance, short service life, etc., to meet the requirements of environmental use, improve Mechanical properties, the effect of eliminating splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

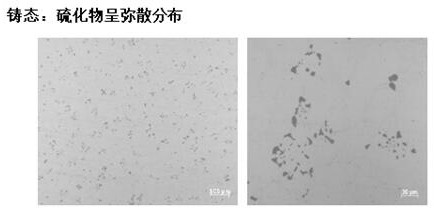

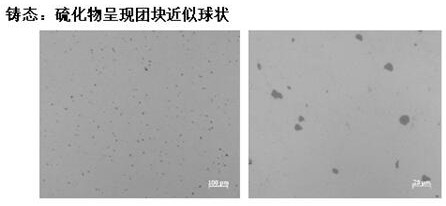

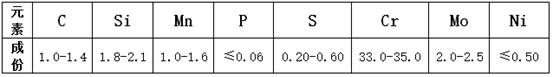

[0014] See figure 2 As shown, a method for improving the performance of high-carbon and high-chromium wear-resistant and corrosion-resistant materials, its chemical composition: C is 1.0-1.4, Si is 1.8-2.1, Mn is 1.0-1.6, P≤0.06, S is 0.20-0.32, Cr is 33.0-35.0, Mo is 2.0-2.5, Ni≤0.50, and the sulfide in the casting adopts approximately spherical agglomerates to eliminate the splitting of the casting matrix by the sulfide. Controlling the Mn content at 1.0-1.6% and controlling the sulfur content at 0.2-0.32% realizes the morphological change of sulfide in the casting structure.

[0015] The testing data of the mechanical properties of the castings are as follows:

[0016]

[0017] Compared with the existing ones, the tensile strength exceeds the standard by nearly 100MPa, and the hardness is further increased, which reduces the risk of brittle cracking of parts during use and improves the service life of parts. Metallographic testing such as figure 2 shown.

[0018] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com