Buoy coloring method

A technology of buoys and marking areas, applied to special surfaces, devices for coating liquid on surfaces, coatings, etc., can solve the problems of low coloring efficiency, improve coloring efficiency, prevent the accumulation of motion errors, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

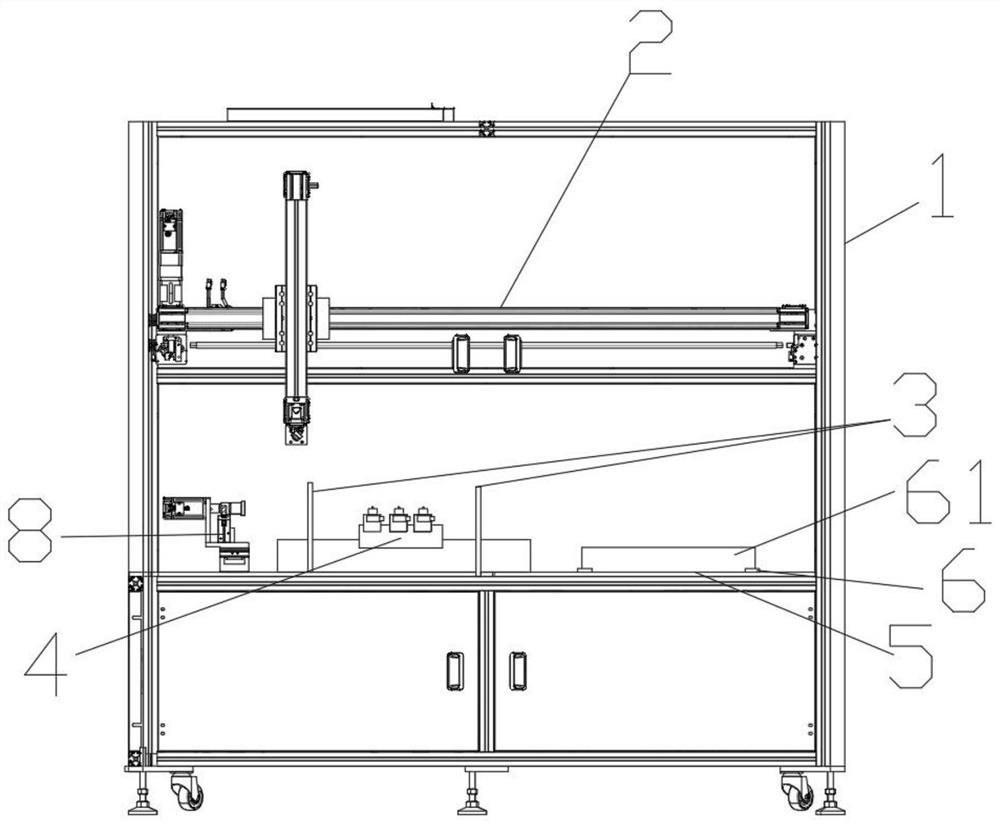

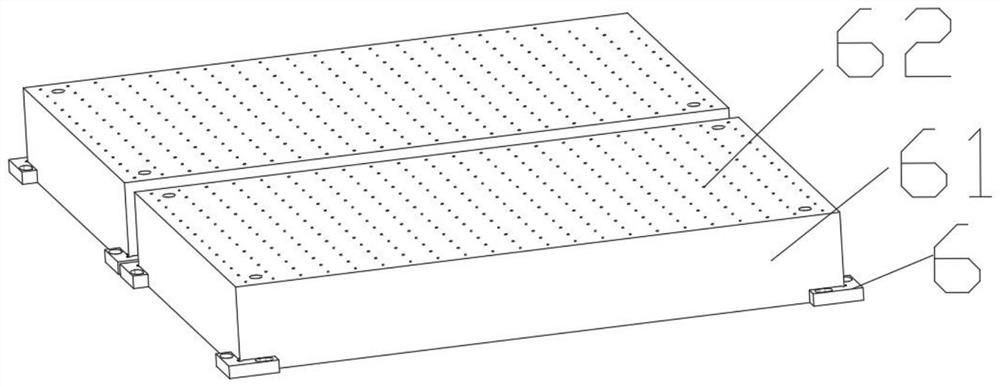

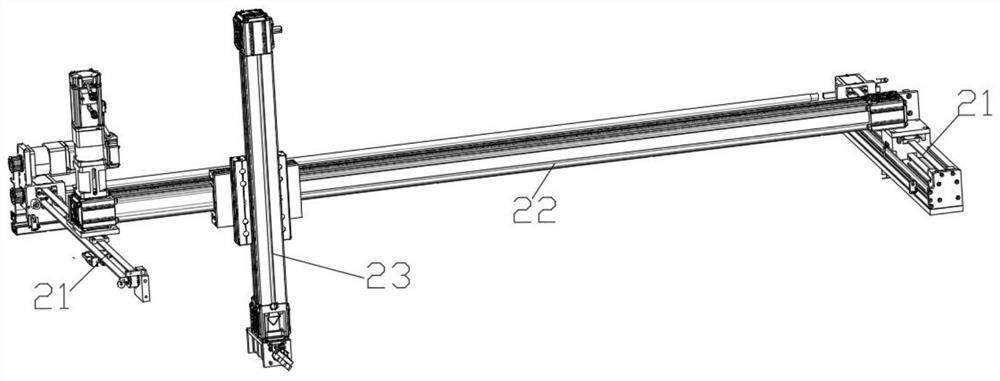

[0038] Such as figure 1 A buoy coloring machine shown includes a frame 1, and the frame 1 is equipped with a three-dimensional moving mechanism 2, and the three-dimensional moving mechanism 2 is equipped with a front end clamp and a rear end clamp; the frame 1 is also equipped with The buoy fixed rotation mechanism 8, the buoy coloring method structure 4 and the buoy support structure 3.

[0039] The use process is: the three-dimensional moving mechanism 2 drives the front-end clamp and the rear-end clamp to move, wherein the front-end clamp is used for retrieving and loading materials, and the movement of the rear-end clamp is used for unloading and discharging materials. In this way, each time the front-end gripper takes the material and then moves to the ink cartridge, the rear-end gripper can perform the unloading operation. After the blanking is completed, the front-end gripper can immediately perform the loading operation. At the same time, after the three-dimensional m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com