Efficient sand screening equipment with dustproof function for road and bridge construction

A technology for bridge construction and screening equipment, which is applied to lighting and heating equipment, filtering, dust removal, etc. It can solve problems such as time-consuming and labor-intensive, decline in screening quality, and health threats to staff, so as to improve processing efficiency, reduce labor intensity, Guaranteed the effect of good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

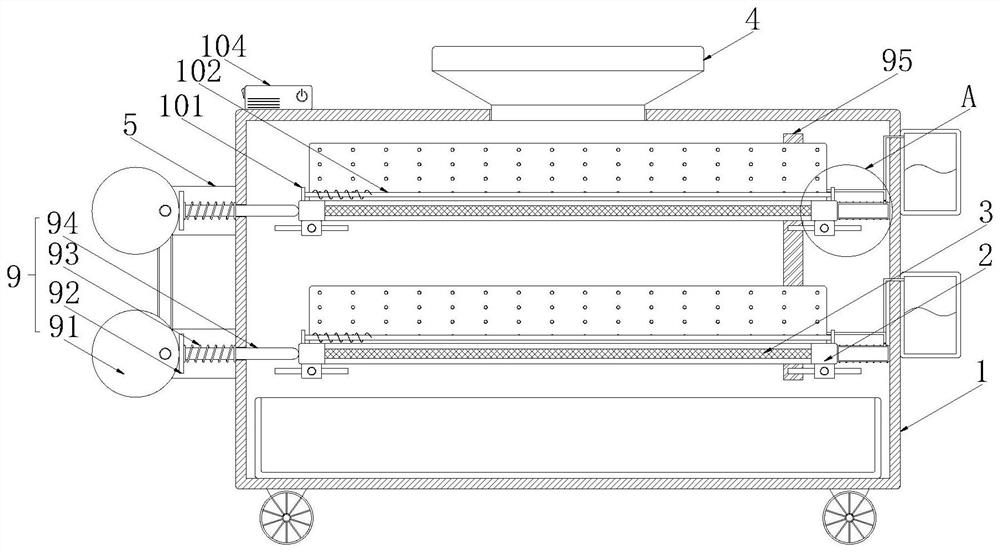

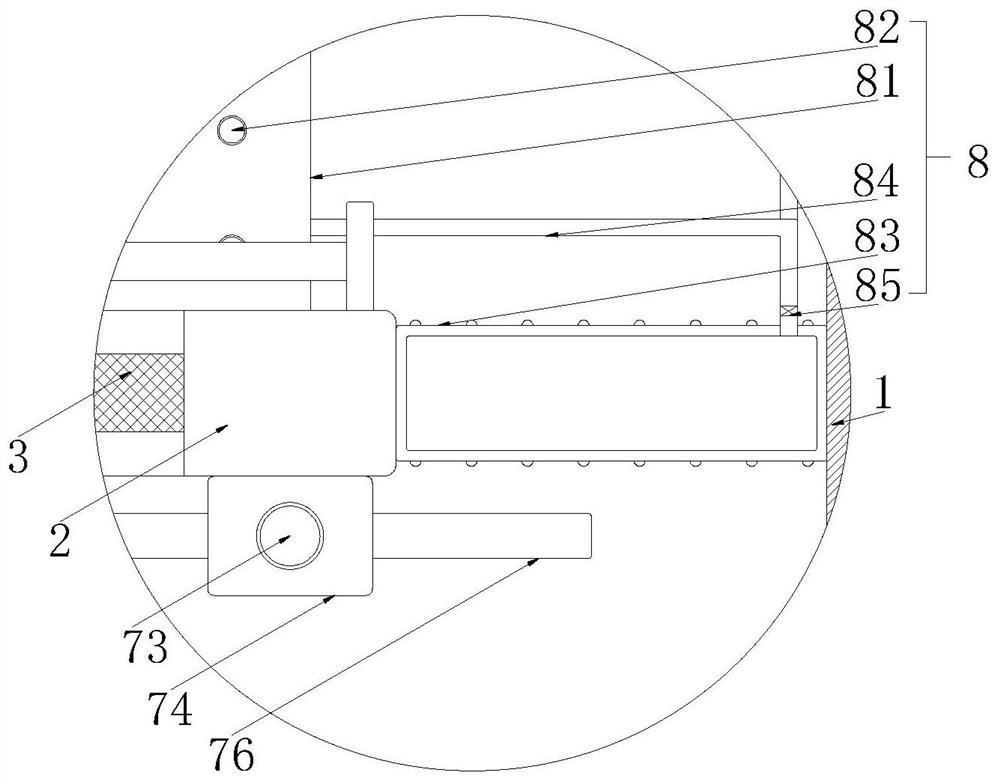

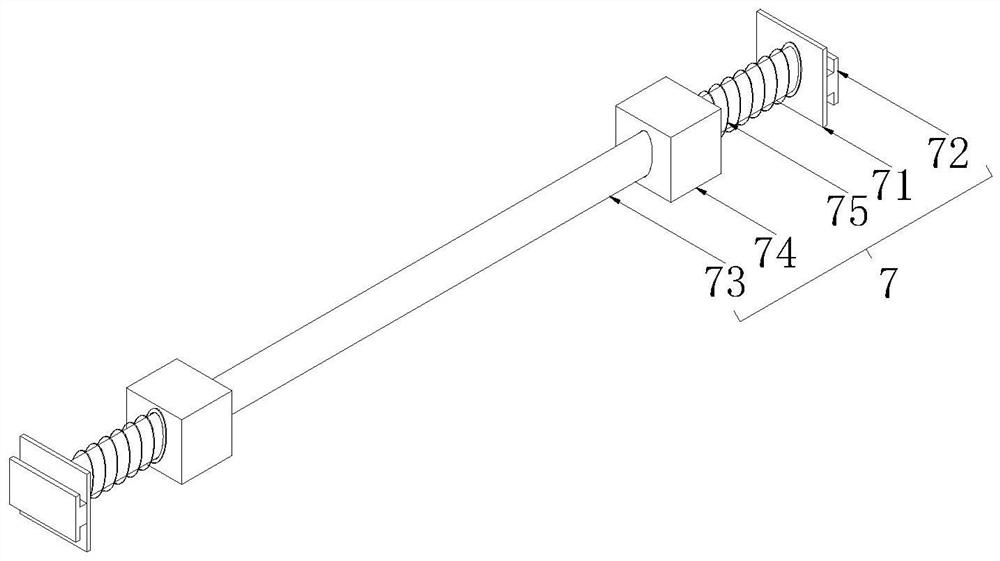

[0028] refer to Figure 1-5 , a high-efficiency sand screening device for road and bridge construction with dustproof function, comprising a box body 1, two screening frames 2 are installed on the inner surface of the box body 1, and the two screening frames 2 are installed on the box body 1 through a guide assembly 7 The inner surface of the guide assembly 7 includes four slide plates 71, four stop blocks 72, two slide bars 73, four slide blocks 74, four springs 75 and two stop slots 76, two slide bars 73 Two by two are fixedly connected between the four sliding plates 71, four sliding blocks 74 are slidingly sleeved on the two sliding rods 73 in pairs, and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com