Rapid automatic battery replacing system and electric automobile

An electric system and fast technology, applied in electric vehicles, charging stations, vehicle energy storage, etc., can solve manufacturing costs, reliability and durability, poor maintainability, complex mechanical devices of power exchange systems, and low flexibility and other issues to achieve the effect of ensuring accuracy and safety, simple and fast grasping and releasing process, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

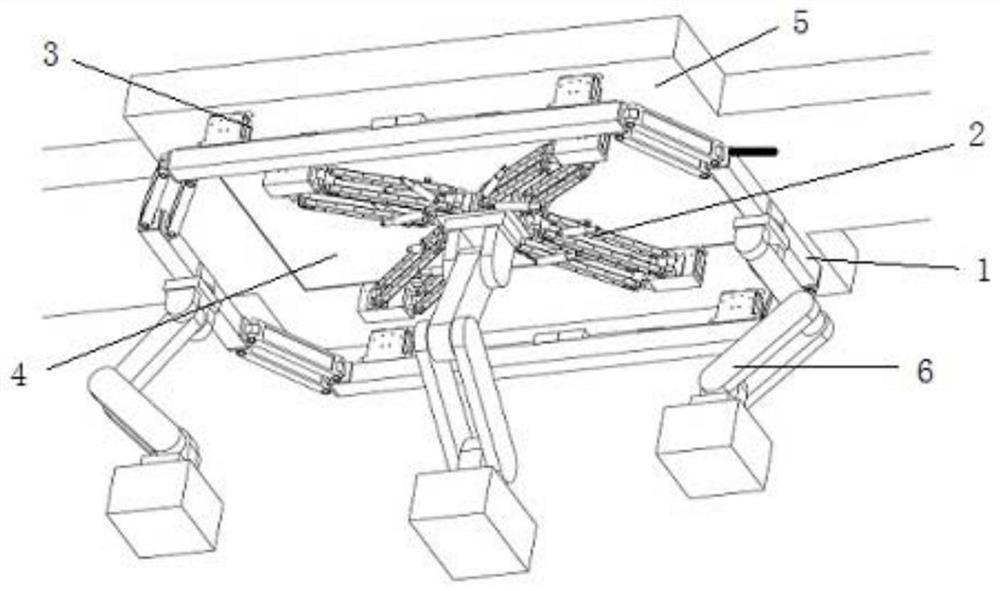

[0079] Such as figure 1 An embodiment shown: a fast automatic power exchange system, including: a vehicle body bracket 1, a battery pack bracket 2, a clamping mechanism 3 and a robot 6; the vehicle body bracket 1 includes: a parallelogram frame main body , wherein the clamping mechanism 3 is arranged on the upper part of one group of relative frames, and is used for clamping the underbody panel 5, and the robot 6 is arranged on the lower part of the other group of relative frames;

[0080] The battery pack bracket 2 includes: an X-shaped frame body, the free end of the frame body is provided with the clamping mechanism 3 for clamping the battery pack 4, and a robot 6 is provided at the center lower part of the frame body. The frame body is on the inner side of the parallelogram frame body;

[0081] The robot is used to drive the vehicle body bracket 1 and the battery pack bracket 2 to move up and down.

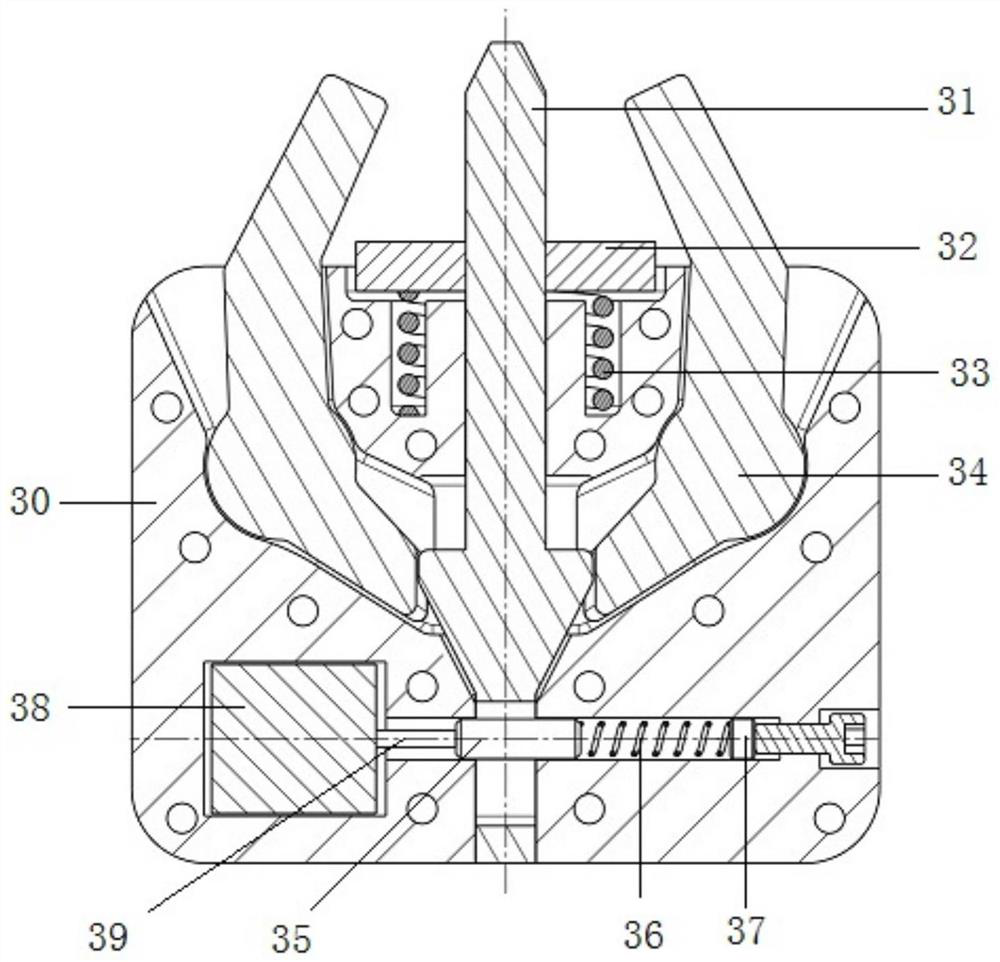

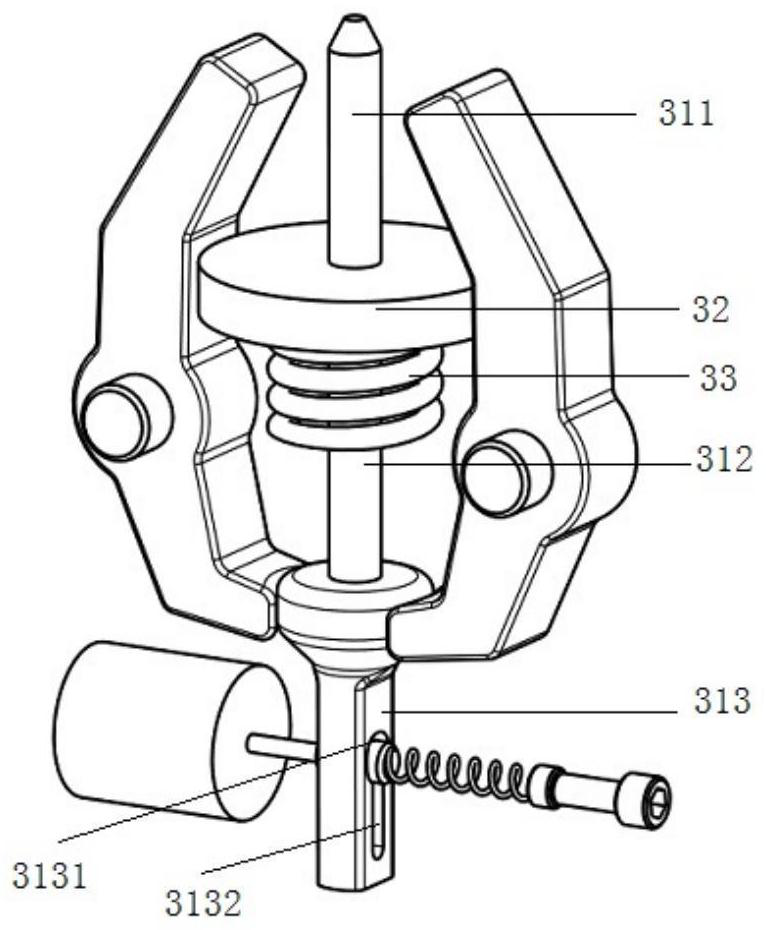

[0082] Such as Figure 2~3 As shown, the clamping mechanism 3 includes...

Embodiment 2

[0113] Such as Figure 16~18 In another embodiment shown, this embodiment modifies the constraining bracket in the above embodiment, and adopts an adjustable constraining bracket 228, and the adjustable constraining bracket 228 includes: an electric push rod 2281; At least one set of electric push rods 2281 parallel to each other is arranged between the first adjusting frame 221 and the second adjusting frame 222; The rod 2222 is provided with at least one set of electric push rods 2281 parallel to each other.

[0114] When the battery packs 4 of different brands and different models adopt different dimensions and specifications, the unification of the specifications of the battery packs 4 cannot be realized, and the parallelogram multi-link mechanism is required to be able to adjust in real time to change the relative spacing of the battery pack 4 clamping mechanism 3, thereby To adapt to battery packs 4 with different dimensions and specifications, the distance between the ...

Embodiment 3

[0118] Such as Figure 19~23 An embodiment shown: an electric vehicle, which is applied to the above-mentioned rapid automatic power exchange system, includes: a vehicle body floor 5 and a battery pack 4, the battery pack 4 is connected to the lower side of the vehicle body floor 5, and the vehicle body The surface of the bottom plate 5 and the battery pack 4 is provided with an interface for the clamping mechanism 3 to extend into. The interface includes: a clamped part, a guide hole 52 is provided in the center of the clamped part, and the clamped part Locking grooves 51 are set on both sides of the part. When the clamping mechanism 3 works, its guide rod 31 extends into the guide hole 52, and the upper part of the rotating lock block 34 extends into the corresponding locking groove 51, and is connected with the clamped part. The locking surface on the side is tightly fitted, so as to grasp and hold the battery pack 4 or the vehicle body.

[0119] In this embodiment, under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com