Cooling tail gas treatment system and using method thereof

A technology for tail gas treatment and tail gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as acid rain, acidification of water sources, skin burns, etc., and achieve the effect of reducing blockage and effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

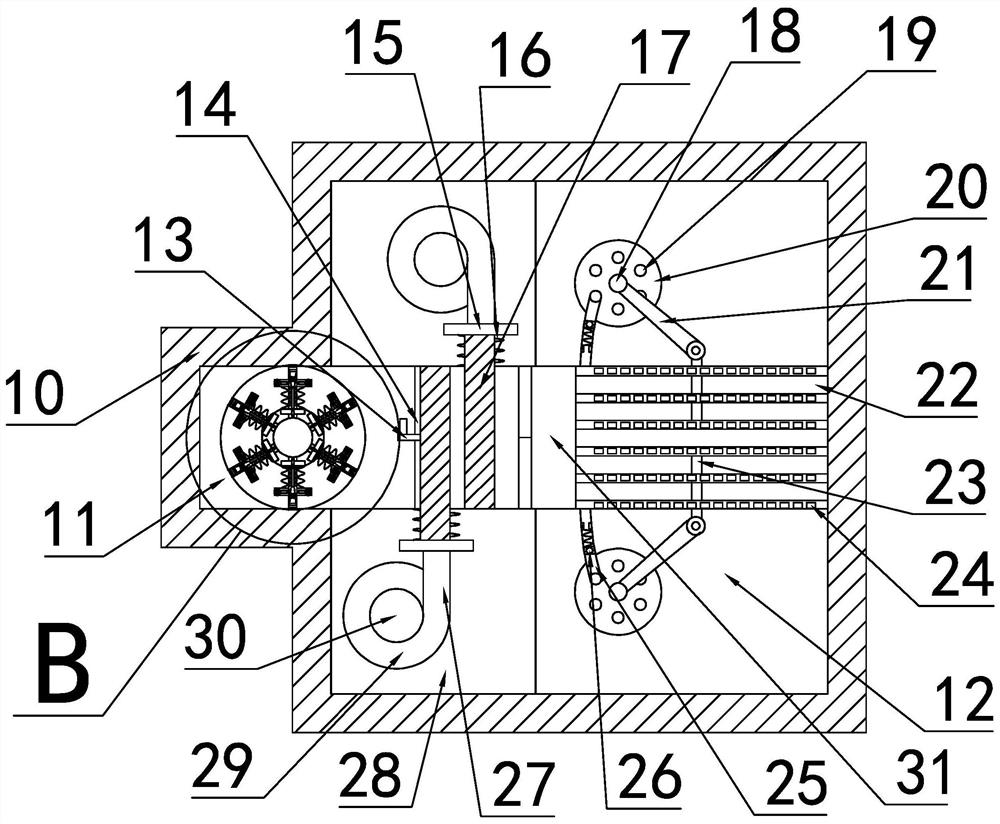

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

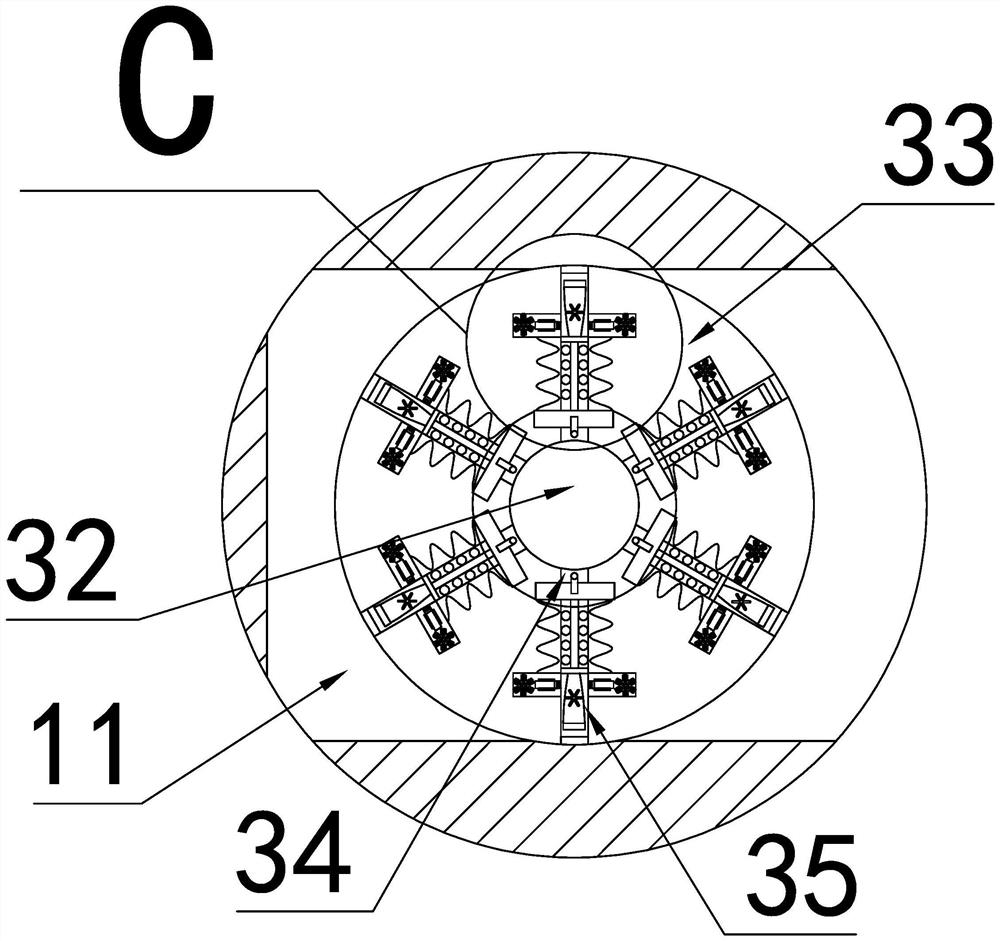

[0029] like figure 1As shown, a cooling tail gas treatment system includes a housing 10, an exhaust port 11 is provided on the upper end wall of the housing 10, a water spray adsorption device and a reciprocating clay device are provided on the exhaust port 11, and the exhaust port 11 The right end wall is provided with a friction filter chamber 28, and the friction filter chamber 28 is provided with a filter friction device. The right end wall of the friction filter chamber 28 is provided with a cooling treatment chamber 12, and the cooling treatment chamber 12 is provided with a water inlet cooling device.

[0030] like figure 1 and figure 2 As shown, the water inlet cooling device includes five cooling tubes 22 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com