Method of plasma arc welding process and motion centralized control system

A technology of centralized control system, plasma arc, applied in plasma welding equipment, general control system, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

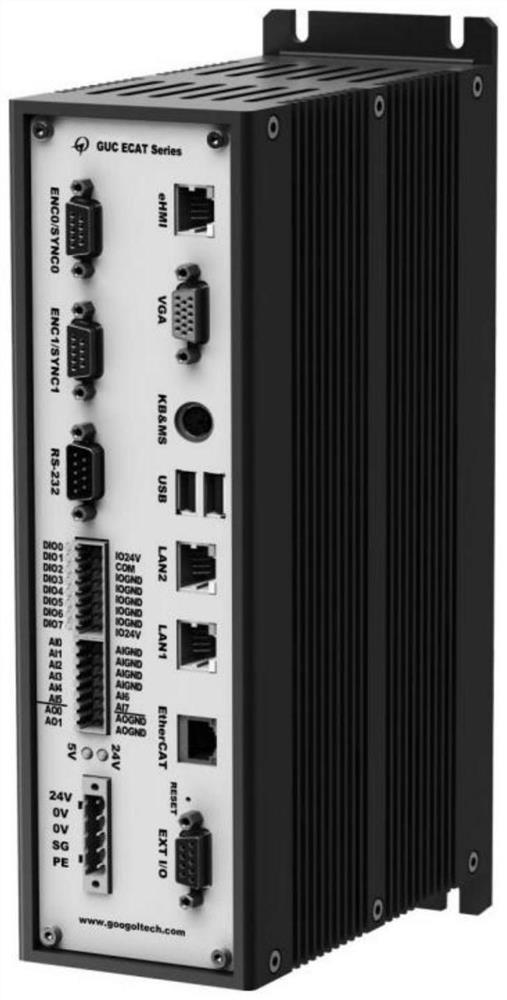

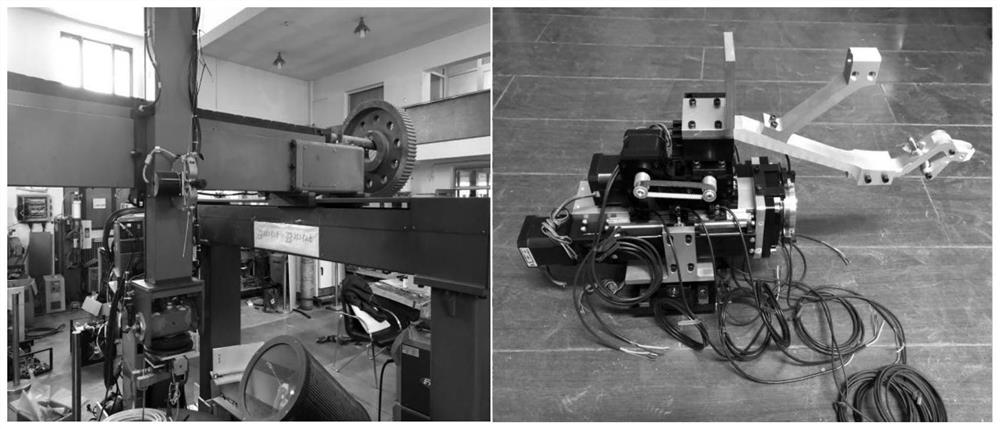

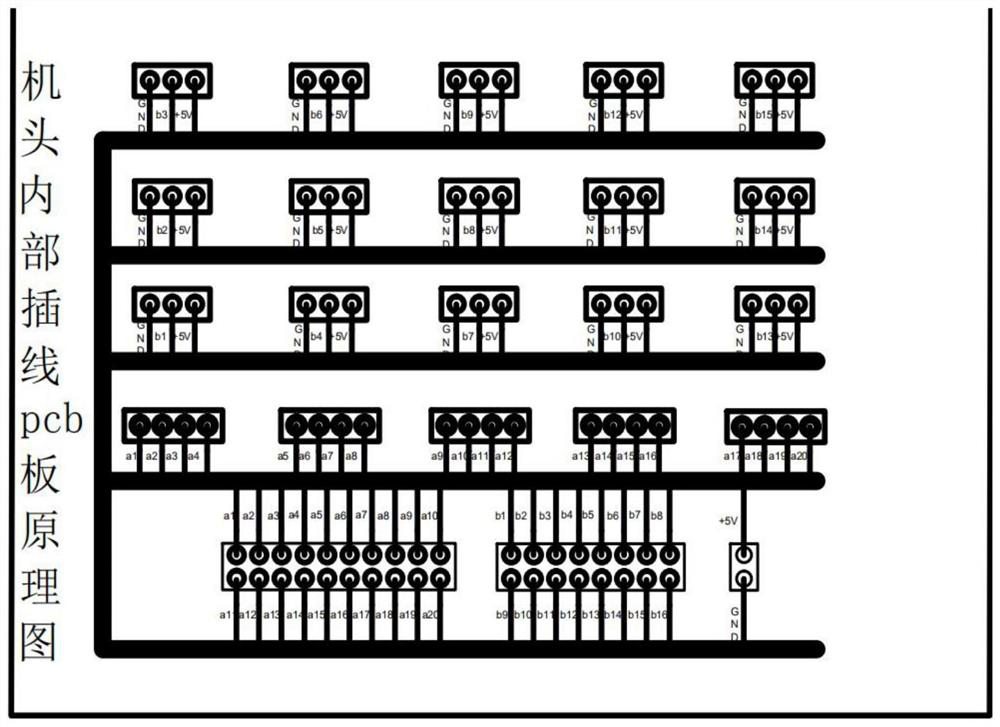

[0023] The equipment used in this embodiment includes: 1. welding Cartesian coordinate system robot, 2. plasma arc welding machine body, 3. GUC-EtherCAT multi-axis motion controller, 4. Otostudio open software platform, 5. Ethercat stepper motor driver and Servo motor driver, 6. Teach pendant.

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings. The present invention is concretely realized according to the following steps:

[0025] (1) Integrate welding special machine process control and welding robot motion control

[0026] Connect the plasma arc welding special frame to the 4+2-axis Cartesian coordinate system robot, that is, the X, Y, Z axes, and the rotation axes of the Z axis and the rotation and rolling axes of the worktable. To achieve the combination of welding process control and motion control, the plasma arc welding machine has a tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com