Automatic walking equipment and system and regression control method and device

A technology of automatic walking equipment and regression control, applied in non-electric variable control, control/regulation system, two-dimensional position/channel control, etc., can solve the problems of large error, low docking accuracy, and unstable equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In one embodiment, the present application provides a self-propelled device. The self-propelled device may be a lawn mower, a sweeping robot, a snowplow, and other intelligent devices with self-propelled kinetic energy.

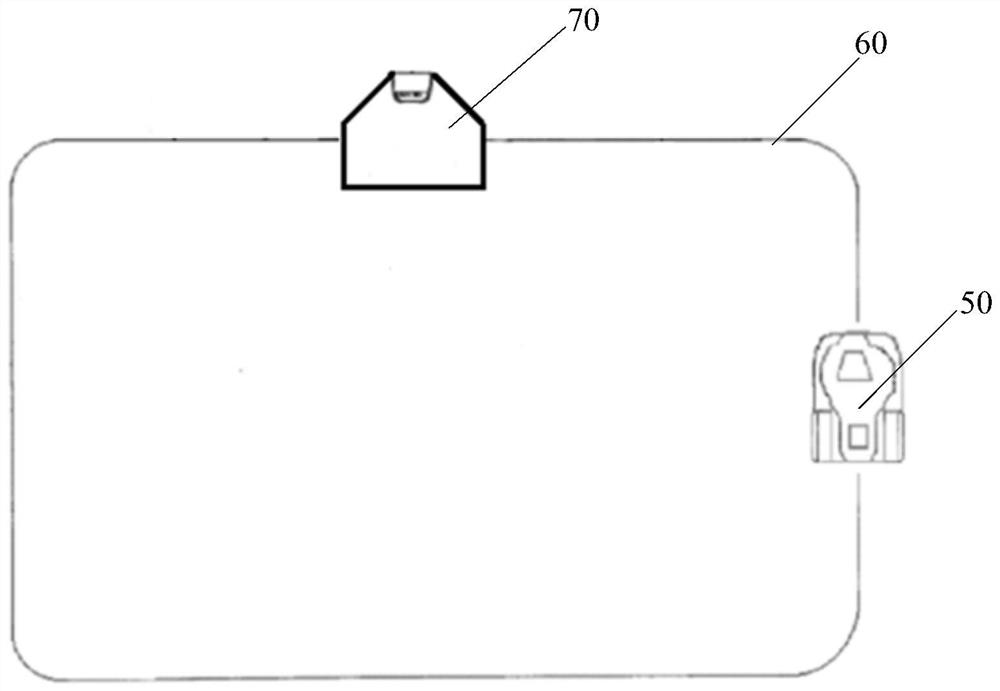

[0079] The self-propelled device provided by the embodiment of the present application includes a working mode and a returning mode. When it is in the working mode, the automatic running device 50 performs work tasks in the boundary line 60, such as mowing or snow removal or mopping the floor; when it is in the return mode, the automatic running device 50 moves to the stop 70 along the boundary line , and dock with the docking station 70 to realize the return function (refer to figure 1 ). Wherein, the boundary line 60 is used to define the working area of the automatic walking device 50, and there is a boundary line signal on the boundary line 60, and the boundary line signal may be a magnetic field signal.

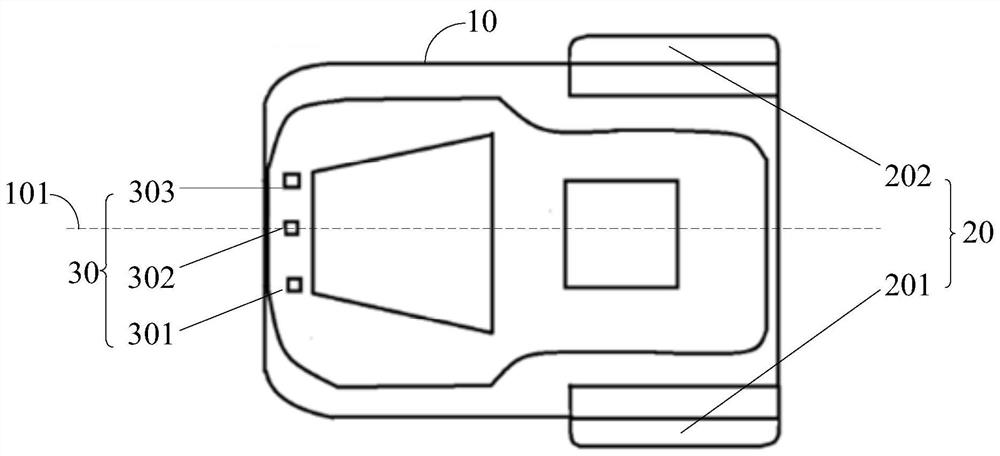

[0080] Such as figure 2 with 3 As s...

Embodiment 2

[0115] In another embodiment, the present application provides an automatic working system, such as figure 1 As shown, it includes a boundary line 60, a docking station 70, and the self-propelled device 50 as described in the first embodiment.

[0116] The boundary line 60 is used to define the working area of the automatic walking device 50 , and the boundary line 60 has a signal of the boundary line 60 . The docking station 70 is arranged on the boundary line 60, and is used for providing pulse current to the boundary line 60 to form a signal of the boundary line 60, and the signal of the boundary line 60 is a magnetic field signal. The docking station 70 also includes a charging module, which is used for docking with the returned automatic running device 50 , and then charging the automatic running device 50 .

[0117] For the specific structure of the automatic walking device 50, please refer to the relevant content in the first embodiment, and details will not be repea...

Embodiment 3

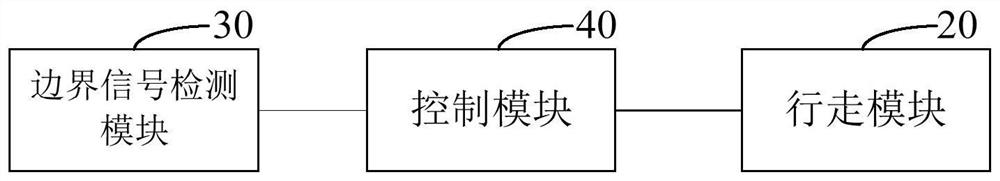

[0120] In another embodiment, the present application provides a regression control method for an automatic walking device 50, the automatic walking device 50 includes a walking module 20, a boundary signal detection module 30 and a control module 40, and the execution subject of the method is the control module 40 For the specific structure of the self-propelled device 50, please refer to the relevant content in the first embodiment, and details will not be repeated here.

[0121] Such as Figure 9 As shown, the regression control method provided in this embodiment includes the following steps:

[0122] Step S20 , controlling the walking module 20 to drive the automatic walking device 50 to move along the boundary line 60 . Firstly, the automatic walking device 50 is controlled to enter the return mode, that is, the walking module 20 is controlled to drive the automatic walking device 50 to move to the boundary line 60 and move back along the boundary line 60 .

[0123] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com