Gradient measuring instrument for constructional engineering floor tiles

A technology for measuring instruments and construction engineering, which is applied in the direction of instruments, measuring devices, measuring inclination, etc., which can solve the problems of inconvenience for measuring personnel, troublesome operation, waste of time, etc., and achieve the effect of simple measurement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

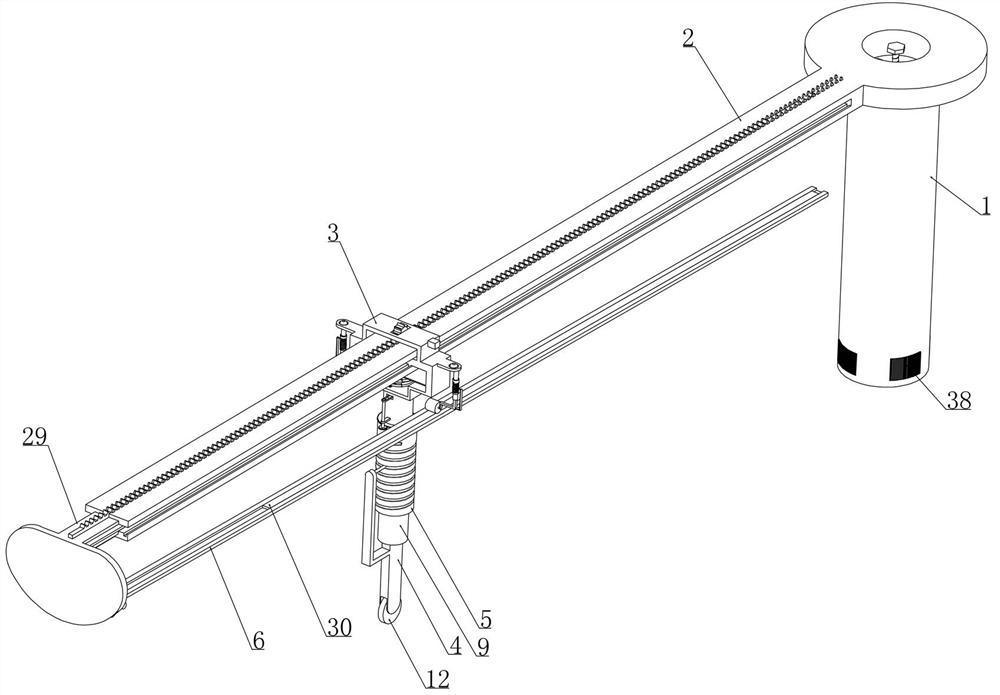

[0027] Embodiment 1, this scheme provides a kind of construction engineering floor tile slope measuring instrument, as attached figure 1 As shown, the base 1 is included and a level is provided on the base 1 (the level is not shown in the figure). When measuring the laying slope of bathroom floor tiles, the surveyor fixes the base 1 at the position of the floor drain and passes The level set on the base 1 adjusts the levelness of the base 1 (so that the base 1 is in a horizontal state to ensure the accuracy of the detection structure), the level is the prior art, and those skilled in the art combine the The design can set the level in the prior art on the base 1, and adjust the levelness of the base 1 according to the level, and when the base 1 is adjusted to a horizontal state, the surveyor will fix and position the base 1 ( to achieve subsequent measurement work);

[0028] The improvement of this scheme is that: a slide bar 2 is installed on the base 1 and a bearing frame 3...

Embodiment 2

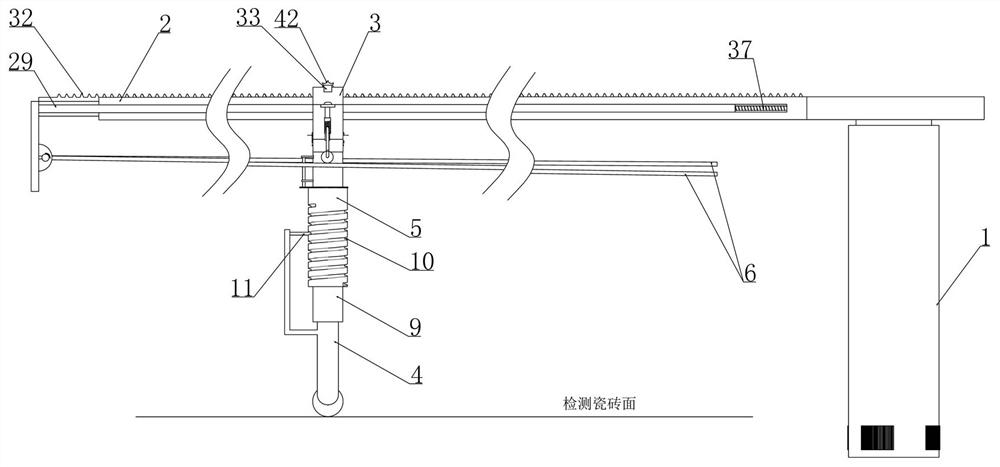

[0035] Embodiment 2, on the basis of embodiment 1, as attached figure 2 As shown, a round rod 9 is integrally provided on the lower end surface of the carrier frame 3 and vertically slides between the detection rod 4 and the round rod 9 (as attached Figure 8 shown), the detection cylinder 5 is rotatably mounted on the round rod 9, and how the detection rod 4 drives the detection cylinder 5 is described in detail below:

[0036] as attached figure 2 As shown, the outer surface of the detection cylinder 5 is provided with a spiral groove 10 and the detection rod 4 is integrally provided with a pin 11 that cooperates with the spiral groove 10 (one end of the head of the pin 11 is located in the spiral groove 10), when the detection rod 4 is opposite to the When the round rod 9 moves vertically, it will drive the detection cylinder 5 to rotate around the round rod 9 through the matching pin 11 and spiral groove 10. It is better to make the detection rod 4 collide with the end ...

Embodiment 3

[0037] Embodiment 3, on the basis of embodiment 2, as attached Figure 9 As shown, the verification device includes a rotating rod 13 that is rotatably installed on the carrier frame 3 and an arc-shaped plate 14 is slidably installed on the rotating rod 13 (a detection spring 15 is connected between the arc-shaped plate 14 and the rotating rod 13), as shown in the attached Figure 11 As shown, the upper and lower ends of the arc-shaped plate 14 are vertically slidably mounted with arc-shaped rods 22 respectively, and a collision spring 16 is connected between the arc-shaped rods 22 and the arc-shaped plates 14. A number of pressure sensors are evenly distributed on the sides. Initially (when the device is working), the side of the pressure sensors installed on the two arc rods 22 is in contact with the calibration device under the action of the conflict spring 16;

[0038] When the measurement work is started, the speed regulating device drives the rotating rod 13 to rotate (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com