Dustproof tool jig for part production

A technology of tooling fixtures and parts, which is applied in the field of dust-proof tooling fixtures, which can solve the problems of difficult dust-proof devices, no protective measures, and reduced device use effects, so as to achieve the effects of dust prevention and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

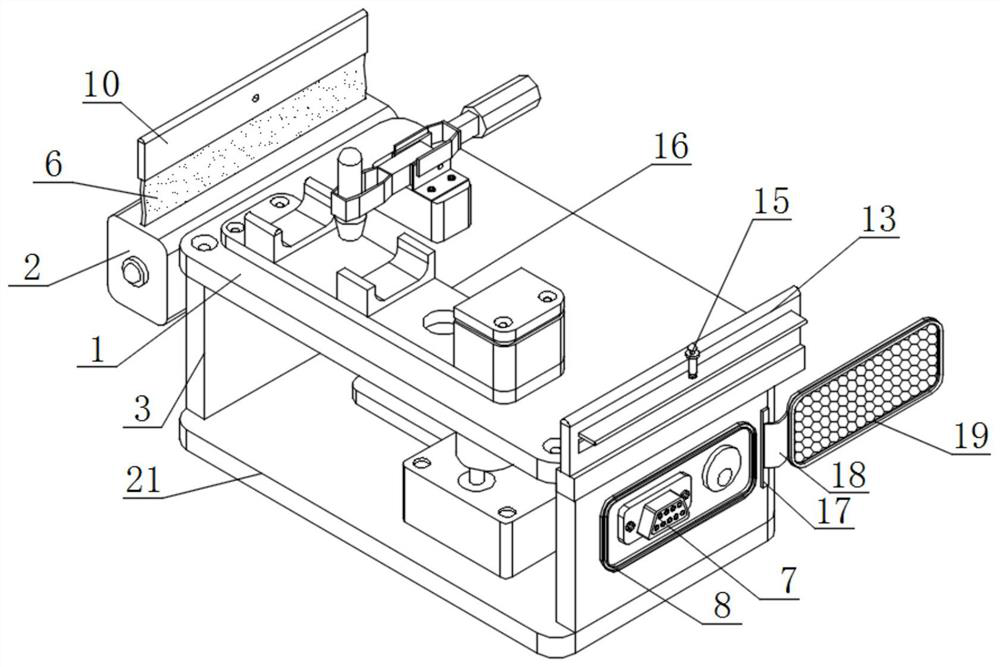

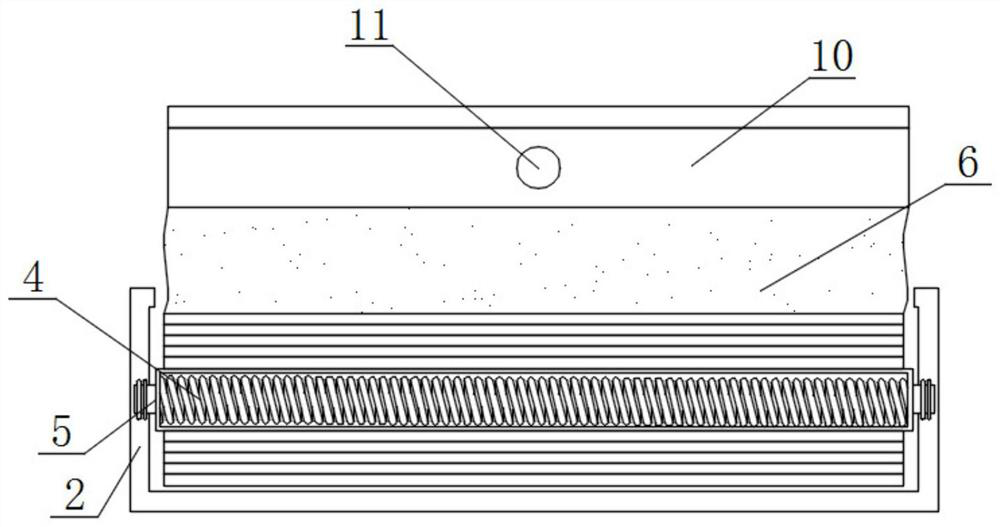

[0026] see figure 1 and figure 2 and Figure 4 , an embodiment provided by the present invention is a dust-proof tooling fixture for parts production, including a work platform 1, a wire take-up box 2 and a fixed panel 3, and a wire take-up box 2 is arranged on one side of the work platform 1, One side of the bottom of the working platform 1 is provided with a fixed panel 3, one side of the inner wall of the take-up box 2 is connected with a torsion spring 4, one side of the surface of the torsion spring 4 is connected with a winding rod 5, and one end of the winding rod 5 is connected to the The inner wall of the take-up box 2, one side of the surface of the winding rod 5 is connected with a dustproof cloth 6;

[0027] When in use, the staff needs to idle the working platform 1 of the device to prevent dust, because a take-up box 2 is installed on one side of the work platform 1, and the inside of the take-up box 2 is connected with a torsion spring 4, and the surface of t...

Embodiment 2

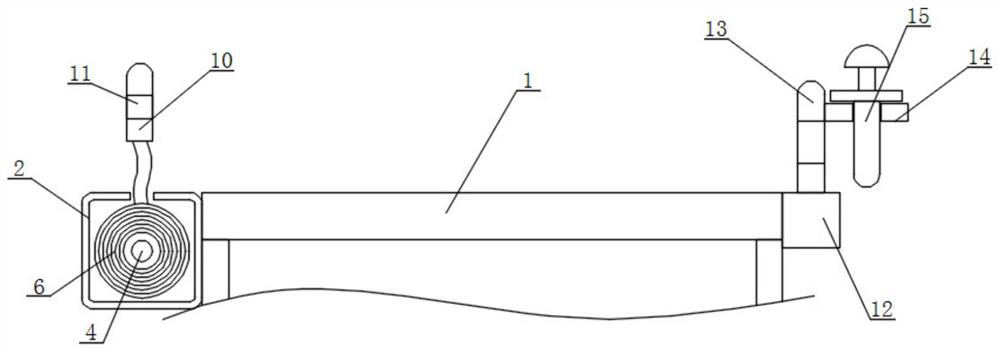

[0029] see figure 1 and figure 2 and image 3 and Figure 4 , an embodiment provided by the present invention, a dust-proof tooling fixture for parts production, including a plug-in interface 7, a mounting panel 8 and a fixed panel 3, one side of the surface of the fixed panel 3 is provided with a plug-in interface 7 , the middle part of the surface of the fixed panel 3 is equipped with an installation panel 8, one side of the surface of the installation panel 8 is provided with a plug-in groove 9, one side of the dustproof cloth 6 is connected with a fixed block 10, and the middle part of the surface of the fixed block 10 is provided with a plug-in slot Hole 11, a connection block 12 is installed on one side of the working platform 1, a plug-in board 13 is installed on the top of the connection block 12, and a connecting plate 14 is installed in the middle of one side of the plug-in board 13, and the middle part of the top of the connecting board 14 passes through the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com