Hub bearing working clearance analysis device and analysis method

A technology of wheel hub bearing and analysis device, applied in the field of wheel hub bearing, can solve the problem of not measuring the wheel hub bearing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

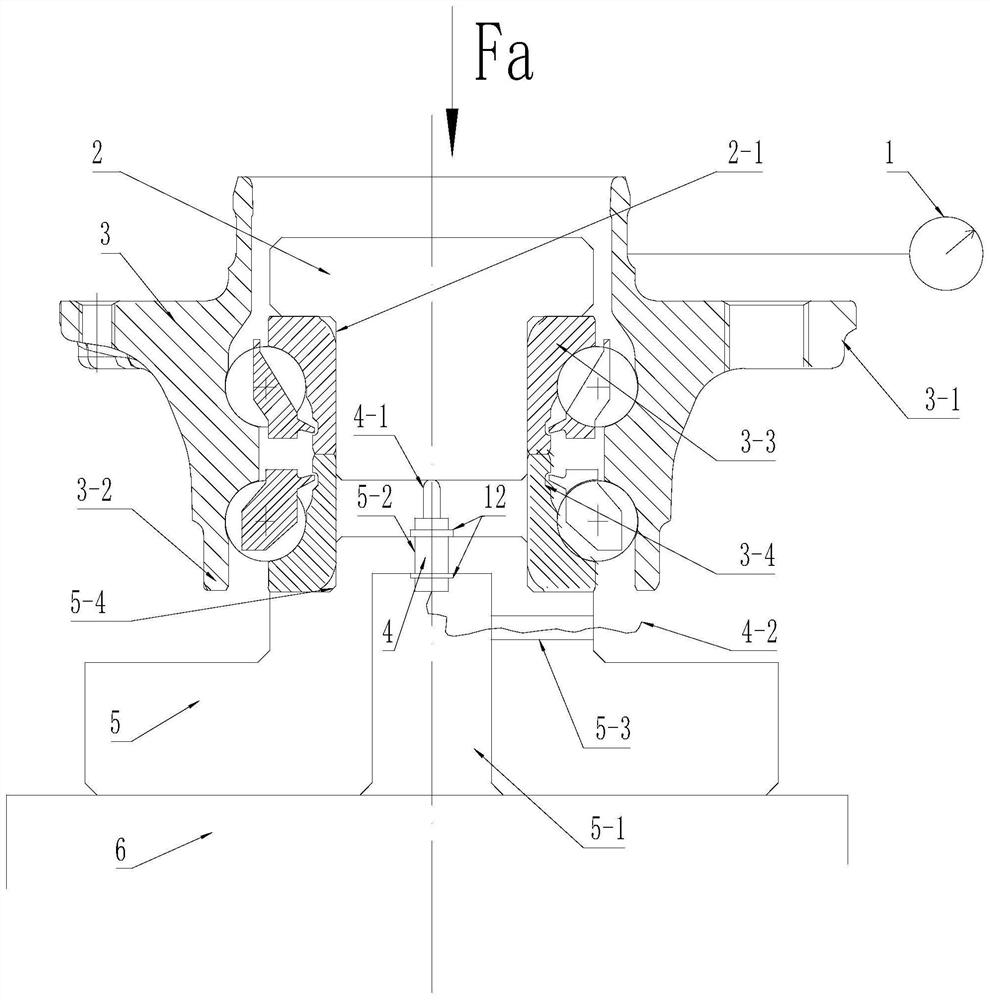

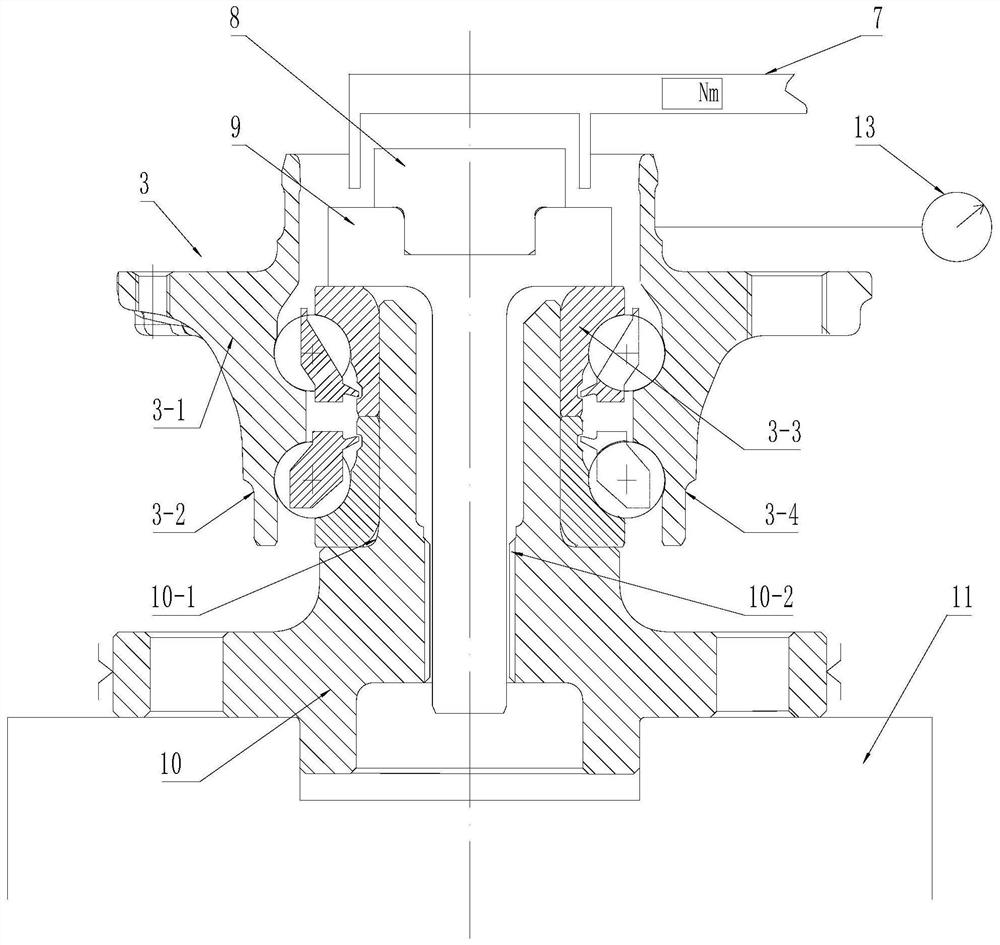

[0026] Embodiment: As shown in the accompanying drawings, a wheel hub bearing working clearance analysis device includes a device for analyzing the clearance of the wheel hub bearing 3. The wheel hub bearing 3 includes a flange 3-1, a bearing inner ring and a cage The rollers held between the flange 3-1 and the inner ring of the bearing, the bearing inner ring includes the upper inner ring 3-3 close to the leading end 3-2 of the flange 3-1 and the upper inner ring 3-3 away from the leading end 3 The lower inner ring 3-4 of -2; the device includes a first analysis device and a second analysis device;

[0027] Reference attached figure 1 , the first analysis device includes a first tension gauge 1, a gland 2, a displacement sensor 4, a support base 5 and a platform 6, and the gland 2 is used to place the upper inner ring axially from the leading end 3-2 3-3, make the bottom of the gland 2 penetrate into the lower inner ring 3-4, and at the same time, the gland step 2-1 provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com