Fabric correction equipment of sewing machine

A sewing machine and fabric technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of difficult adjustment, inconvenient adjustment process, and biased cloth, so as to achieve the effect that it is not easy to be stretched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

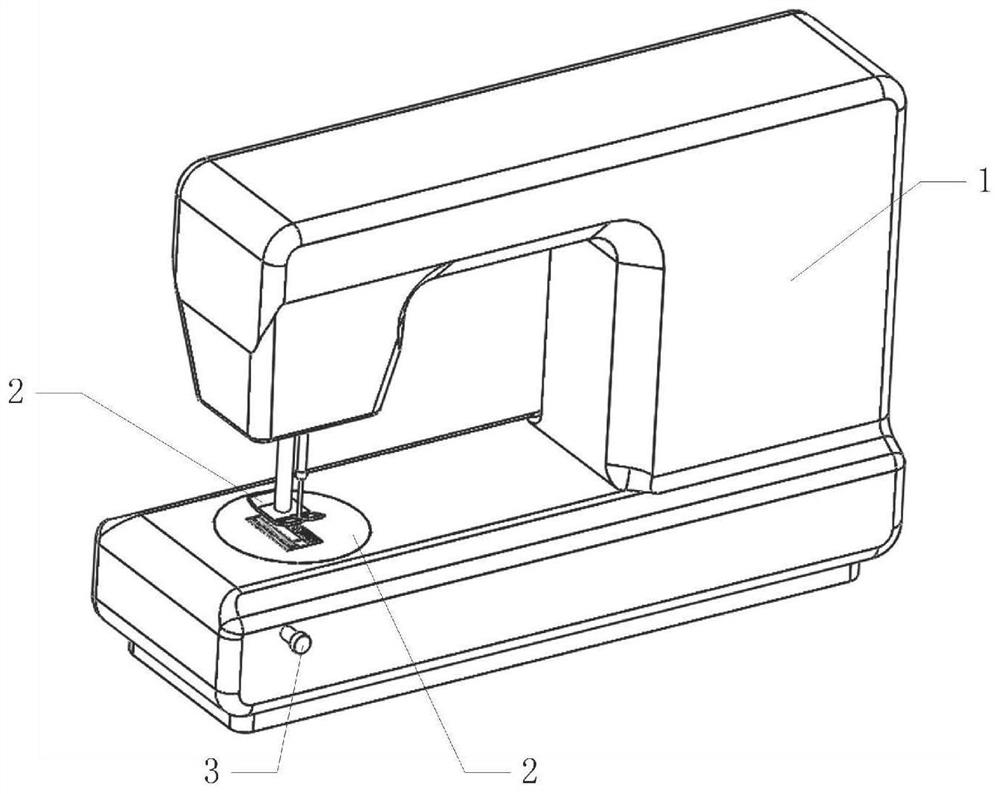

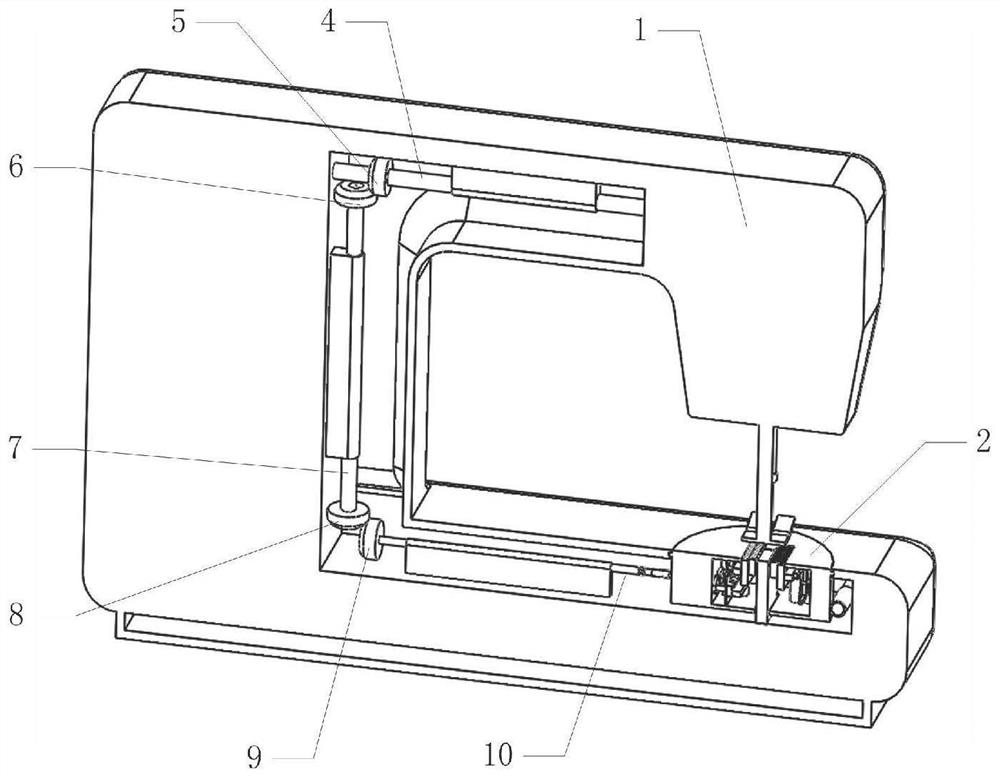

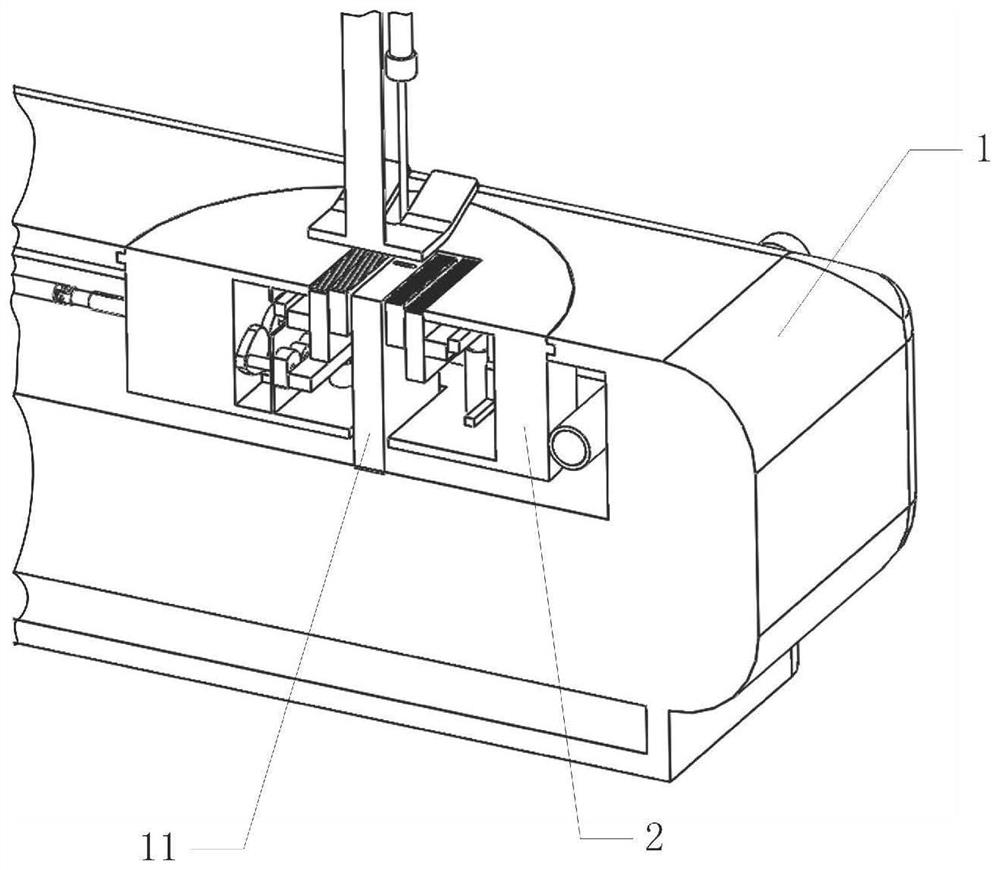

[0035] Such as figure 1 , 2 , 3, it includes a body 1, a rotating mounting case 2, an adjustment rod 3, a pulley wheel module 11, a worm 12, a main shifting tooth plate 16, and an auxiliary cloth moving tooth plate 17, wherein as Figure 7 As shown, the rotating installation shell 2 is provided with an installation through hole 44 of a square shape in the up and down direction, such as figure 2 , 3 As shown, the rotatable installation shell 2 is rotatably installed on the sewing table at the lower side of the body 1, and the rotatable installation shell 2 is located at the lower side of the presser foot 45; Figure 4As shown, there are worm teeth on the outer circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com