Technical field of reinforced spliced two-way folio tent

A spliced and reinforced technology, applied in building types, walls, roofs, etc., can solve the problems of tent deformation and collapse, weak strength of the connection between supports and pillars, bending deformation, etc., to ensure safety and improve overall firmness. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

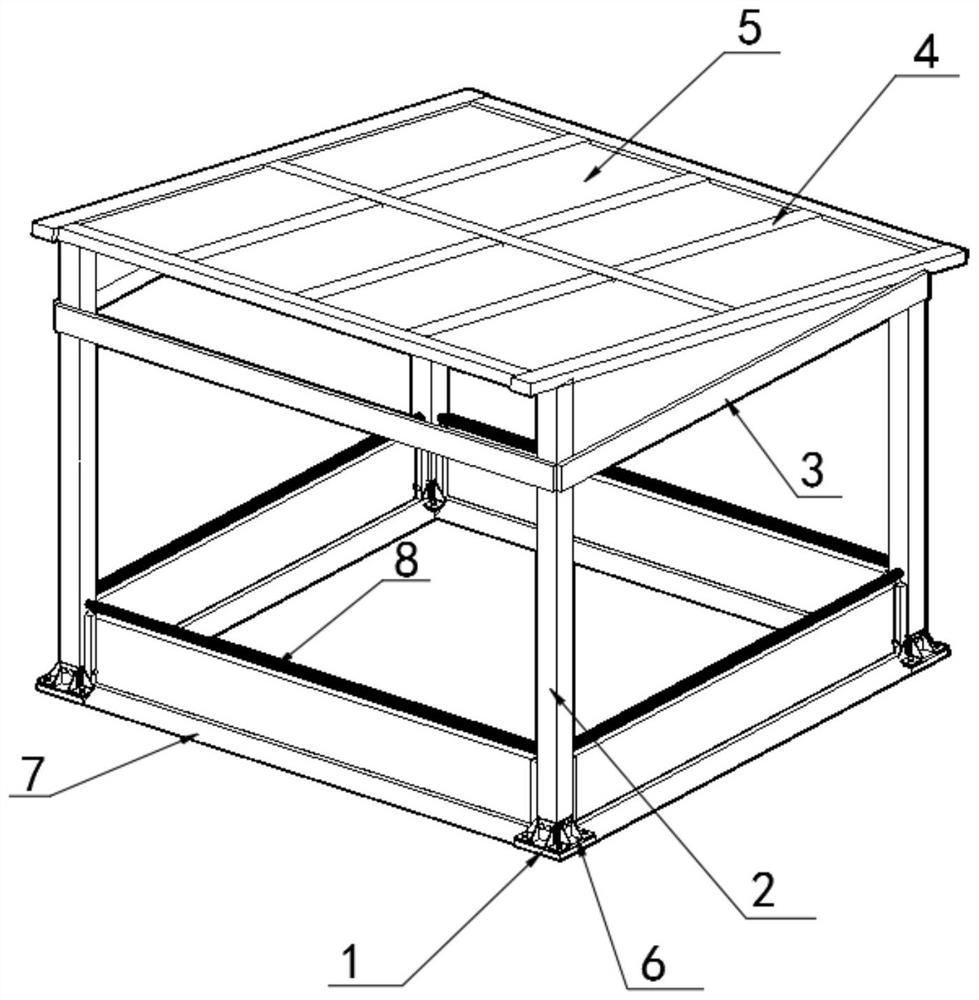

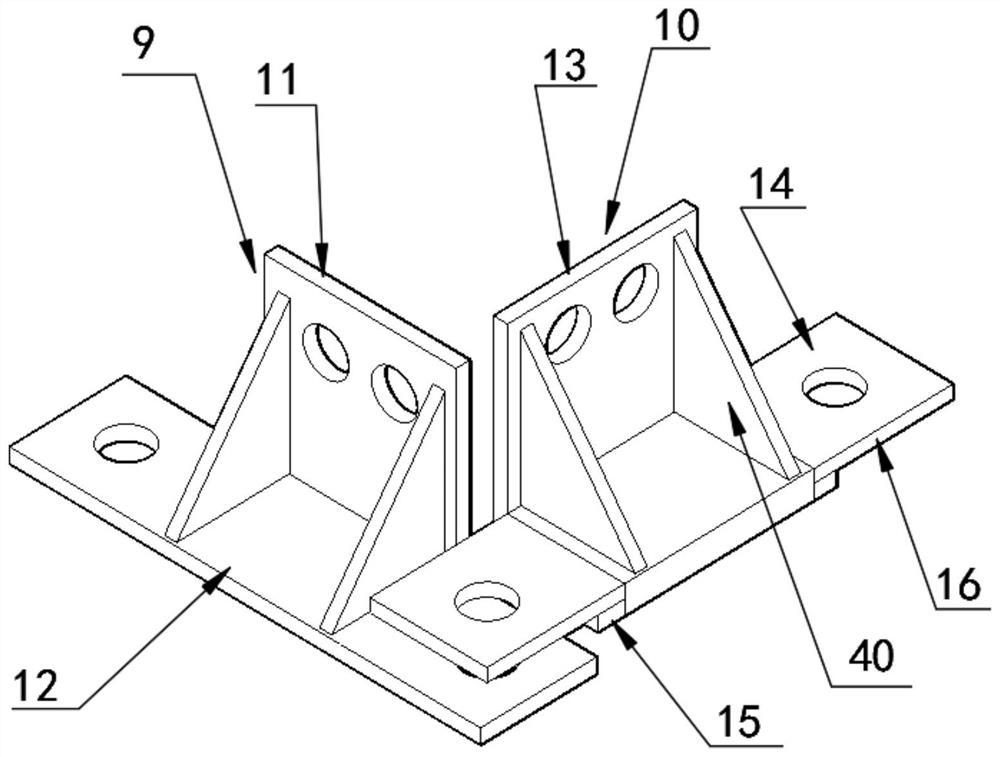

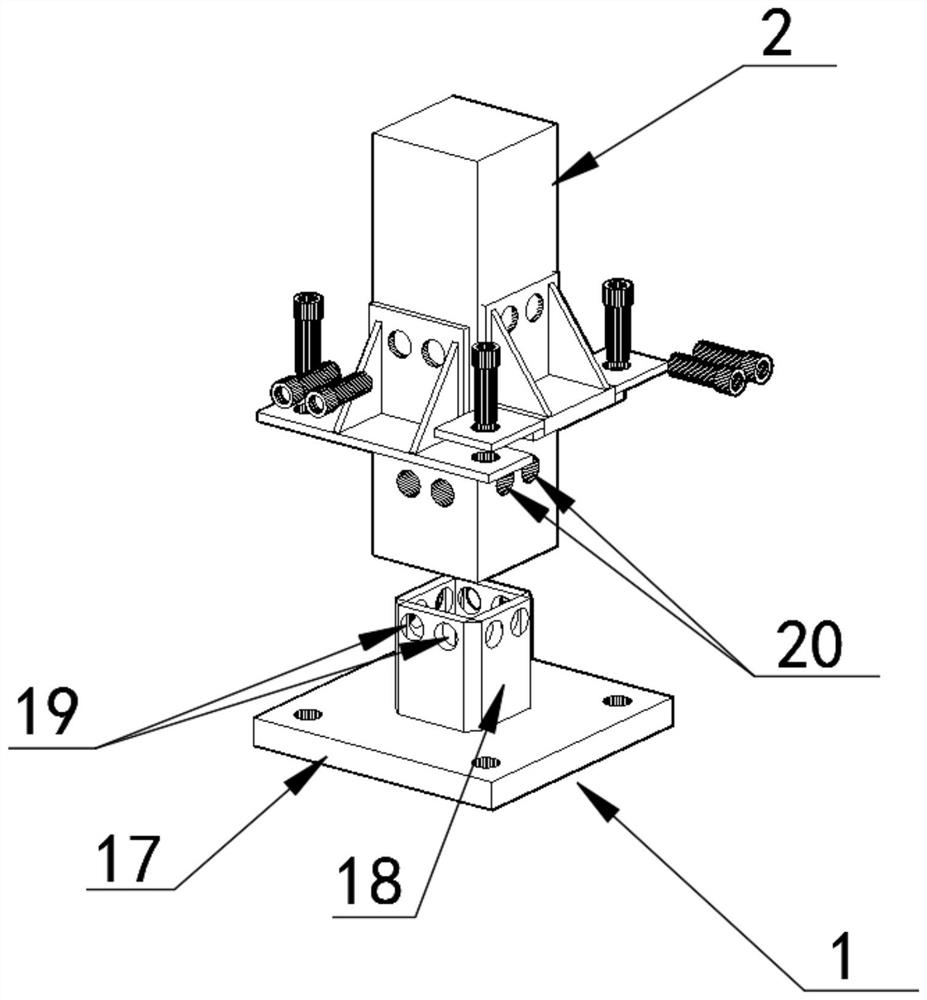

[0042] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Concerning the specific mechanical structure of the present invention, refer to below Figure 1 to Figure 6 The detailed description of the structure will clearly show that the structural content mentioned in the following embodiments are all based on the accompanying drawings.

[0043] Such as Figure 1 to Figure 6 As shown, the reinforced splicing two-way split tent of this embodiment includes a support 1 and a pillar 2, the number of the support 1 and the pillar 2 is not less than four, and the upper ends of the four pillars 2 are connected with beams 3. Slide rails 4 are fixed on the upper parts of the two opposite beams 3, and top plates 5 are fixed inside the slide rails 4. A reinforcement plate assembly 6 is provided between the support 1 and the pillar 2, and a reinforcing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com