Self-suction sand dredger

A technology of sand mining and self-priming, applied in special purpose ships, mechanically driven excavators/dredgers, transportation and packaging, etc. The effect of sand and gravel blocking the pipeline and increasing the liquid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

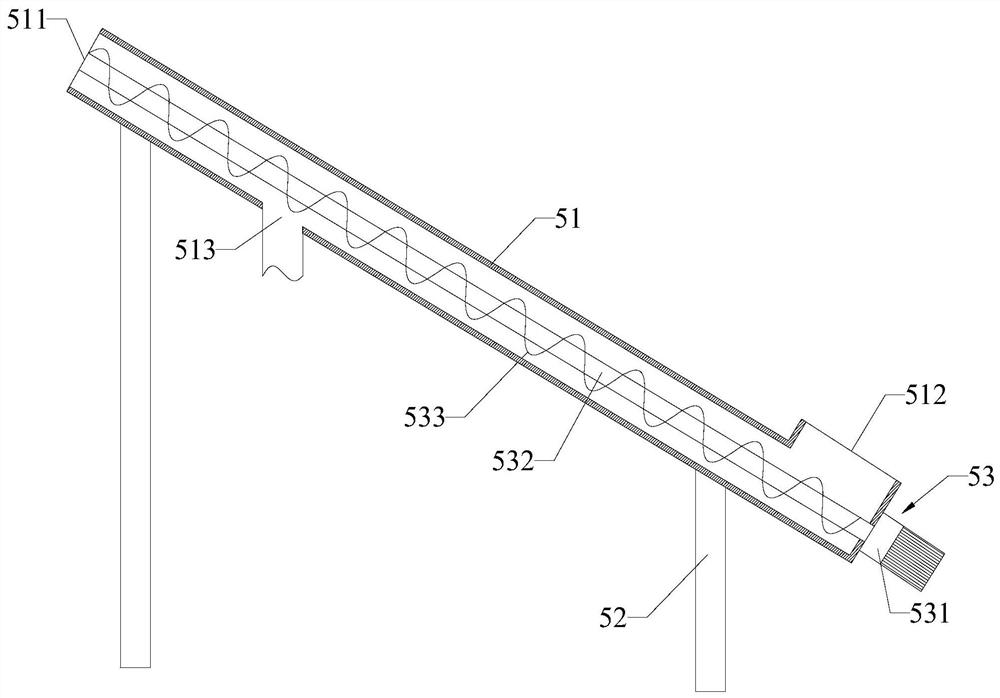

[0025] The application scene of a self-priming sand mining ship of the present invention is: in the process of extracting sand and gravel in the river channel by the sand mining ship, since the inner diameter of the mixing pipe is smaller than the inner diameter of the water outlet pipe of the circulating water tank, the water outlet pipe of the circulating water tank When the water inside enters the mixing pipe of the mortar pipe through the adapter, the flow rate will increase, so that the sand and gravel can be quickly sent to the next process.

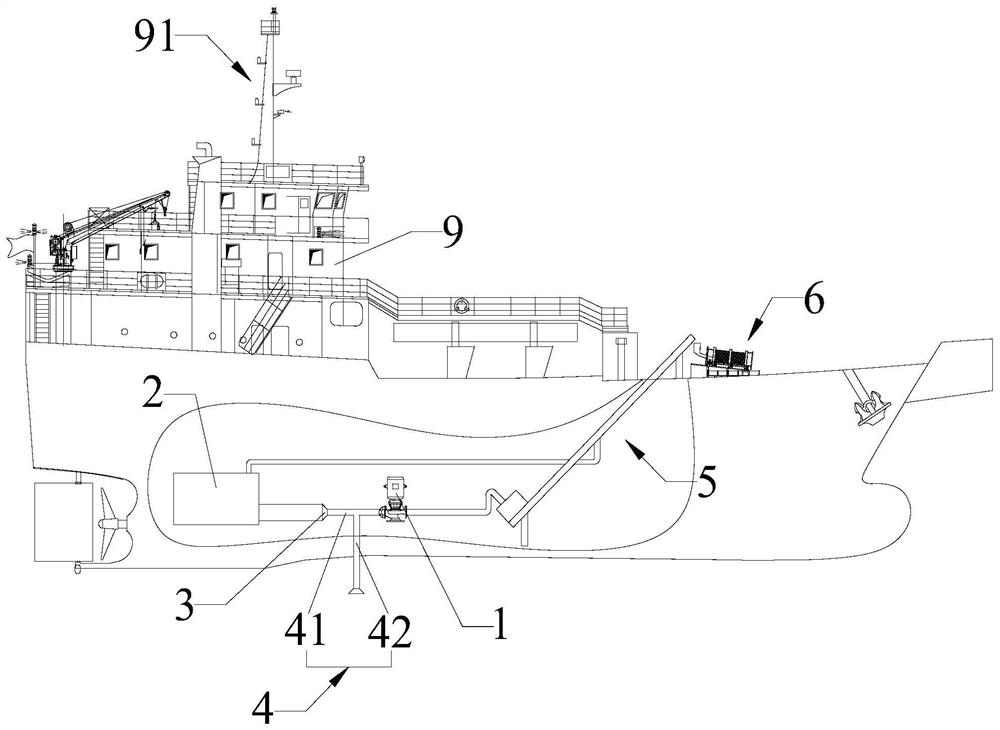

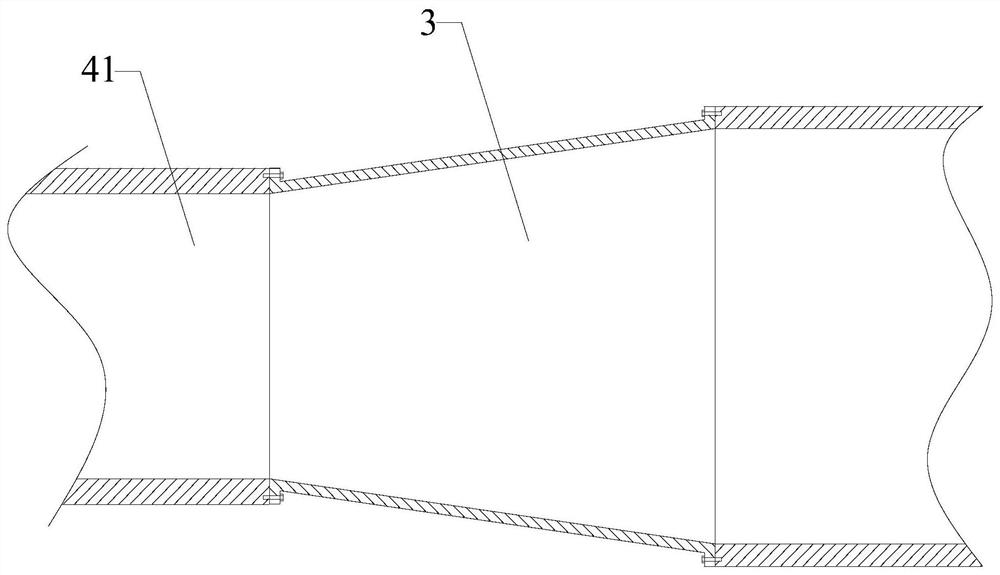

[0026] Please refer to Figure 1 to Figure 2 Shown, a kind of self-priming dredging ship comprises adapter 3, and all is arranged on the mortar pump 1 and circulating water tank 2 in the cabin of dredging ship, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com