Zero-steering electric mower

A lawn mower and electric technology, which is applied to the chassis of harvesters, cutters and agricultural implements, etc., can solve the problems of affecting lawn life, high labor cost, poor operation quality, etc., so as to improve operation performance and improve operation adaptability. good performance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Attached below Figure 1-11 Specifically describe the detailed structure and setting relationship of each component in this embodiment:

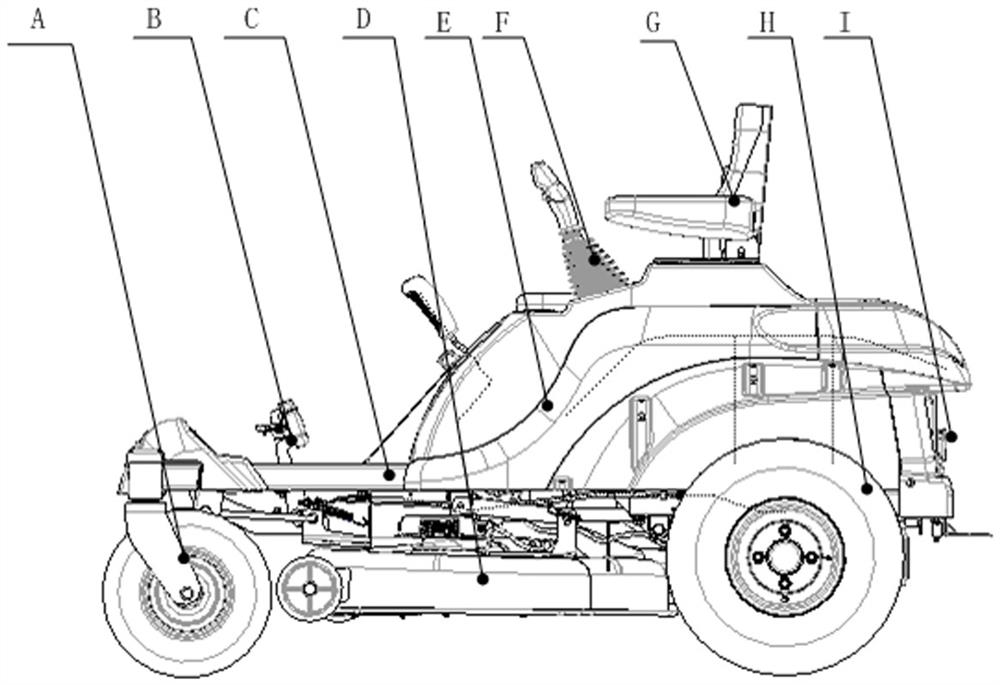

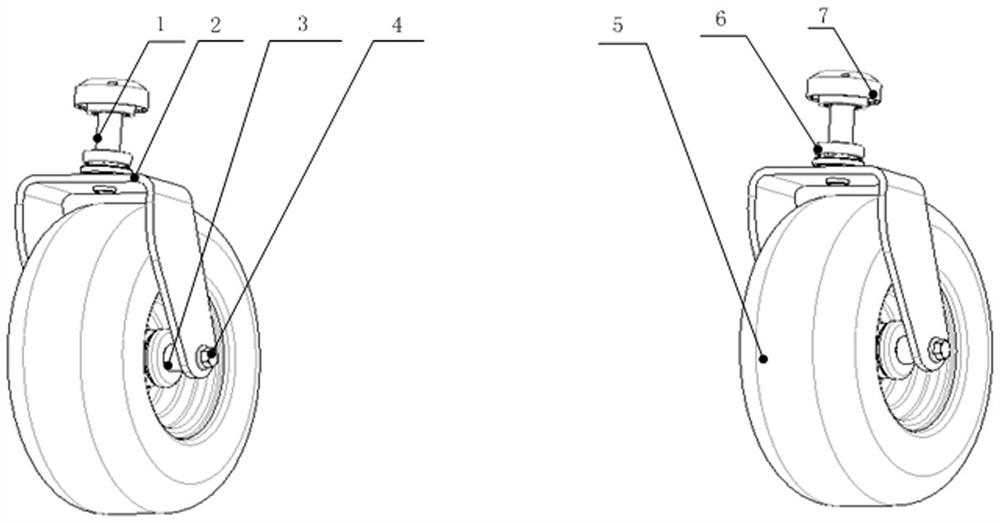

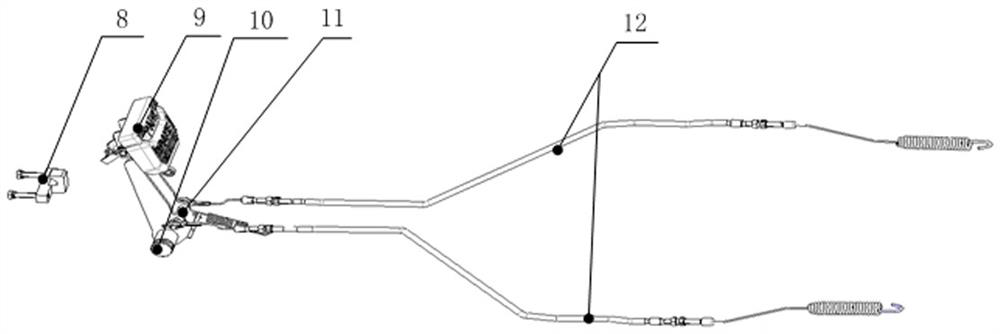

[0054] In this embodiment, the directions described are based on the direction of the front of the lawnmower as the front, as shown in the attached figure 1 Shown: a zero-turn electric lawn mower, which can be used for gardening lawn trimming and other operations, mainly including: universal front wheel assembly A, emergency brake parking brake assembly B, integral welded frame assembly C , Central mowing disc and height adjustment assembly D, cover parts and console assembly E, driving control assembly F, seat assembly G, wheel side deceleration drive wheel assembly H and energy system assembly I;

[0055] The integral welded frame assembly C is the assembly basis of the whole lawn mower. Other parts are directly or indirectly assembled and fixed on the frame. The integral welded frame assembly C can greatly improve the structural s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com